General Applications Of Beryllium Copper

Beryllium Copper (BeCu) or Beryllium Bronze is a high‐performance copper alloy containing between 0.2 and 2 % beryllium. This composition produces quantifiable characteristics: high strength, good electrical and thermal conductivity, resistance to corrosion, non‐magnetic behaviour and spark resistance.

Accordingly, Beryllium Copper is used in electronics, aerospace and the oil and gas industries. The following outlines the common applications of Beryllium Copper:

1. Elastic and Conductive Components

Beryllium Copper alloys are employed in the manufacture of elastic conductive components such as switches, connectors and spring contacts. Its strength is nearly double that of other copper alloys. Beryllium Copper also offers high conductivity. Consequently, it withstands repeated bending without fatigue or deformation.

In the telecommunications and electronics industries, Beryllium Copper is used to produce signal connectors, electrical contacts and battery terminals. These components require precision and durability in compact designs.

2. Wear‐Resistant Bearings and Bushings

Due to its wear resistance, Beryllium Copper is frequently used in sliding bearings and bushings. These parts are subject to friction, vibration and significant loads. The fatigue resistance of Beryllium Copper supports long-term operation.

For example, in the aerospace sector, American Airlines replaced conventional copper bearings with Beryllium Copper bearings. This modification yielded operational lifetimes varying between 8 000 and 28 000 hours. Consequently, downtime and maintenance costs are reduced.

3. Explosion-Proof Tools

A further quantifiable property of Beryllium Copper is its non-sparking behaviour. Tools made from conventional metals may emit sparks when striking a hard surface, thereby increasing safety risks in explosive environments such as oil refineries, chemical plants and mines.

Tools manufactured from Beryllium Copper eliminate this risk. They are used in wrenches, screwdrivers, hammers and chisels where flammable gases or vapours are present. This meets strict safety requirements in hazardous work environments.

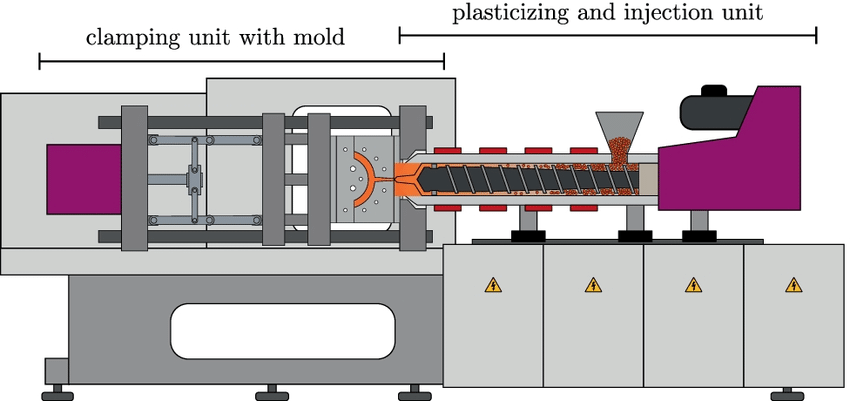

4. Precision Moulds and Die Casting

Beryllium Copper exhibits good thermal conductivity, high hardness and resistance to thermal deformation. Consequently, it is suitable for use in moulds, particularly for plastic injection and die-casting. Its high thermal conductivity also enables the rapid cooling of plastic parts.

Moulds made from Beryllium Copper deliver a high surface finish and low thermal fatigue and are capable of maintaining tight tolerances. In addition, the reusability of this alloy lowers overall production costs in mould making.

[1]

[1]

5. Electrical Components with High Conductivity

For applications that require both high strength and high electrical conductivity, certain Beryllium Copper alloys, namely Cu-Ni-Be and Co-Cu-Be, are used. These alloys can achieve an electrical conductivity of up to 50 % IACS (International Annealed Copper Standard). They are employed for electrical contacts, electrodes and in high-performance relays.

For example, electrodes for resistance welding are manufactured using these alloys. Such electrodes must transmit high electrical currents and withstand mechanical wear and thermal stress.

Types of Beryllium Copper Alloys

Beryllium Copper alloys are divided into two categories:

- High conductivity Beryllium Copper (0.2 %–0.6 % Be): The focus is on conductivity rather than strength; used in electrical applications.

- High strength Beryllium Copper (1.6 %–2.0 % Be): Provides maximum strength while maintaining high conductivity; appropriate for structural and mechanical applications;

They can also be classified into four primary types according to the American standard:

1. C17200 (1.8–2.0 % Be)

- Maximum strength of up to 200 ksi following heat treatment, with high fatigue and wear resistance.

- Used in aerospace, precision instruments, connectors and moulds.

2. C17300 (0.2–0.6 % Be, with lead addition)

- Lower strength with improved machinability.

- Employed in the manufacture of electrical connectors, switches and fasteners.

3. C17500 (0.4–0.7 % Be, with cobalt addition)

- Good electrical and thermal conductivity with moderate strength.

- Used in components for resistance welding and electrical contacts.

4. C17510 (0.4–0.7 % Be, with nickel addition)

- Provides higher strength than C17500 while retaining good conductivity.

- Used in electrical systems in the automotive and aerospace industries.

Further information: Common Types of Beryllium Copper

Conclusion

The strength and quantifiable properties of Beryllium Copper render it useful across various industries. It is applied in electrical connectors and in the manufacture of non-sparking tools. Beryllium Copper alloys consistently fulfil the technical requirements of these applications. Additional Beryllium Copper alloys are available at Stanford Advanced Materials (SAM).

Summary Table: General Applications of Beryllium Copper

|

Applications |

Properties |

Examples |

|

Elastic and Conductive Components |

High strength, elasticity, good conductivity |

Springs, connectors, switching contacts, battery terminals |

|

Wear‐Resistant Bearings & Bushings |

High wear resistance, fatigue endurance |

Aerospace bearings, bushings |

|

Explosion-Proof Tools |

Non-sparking, corrosion resistant |

Hammers, wrenches, chisels |

|

Precision Moulds and Die Casting |

High hardness, thermal conductivity |

Plastic injection moulds, die-casting, precision tool manufacture |

|

Electrical Components with High Conductivity |

Strength and conductivity (up to 50 % IACS) |

Welding electrodes, electrical contacts, relay components |

Reference:

[1] Baum, Markus & Jasser, Fabian & Stricker, Michael & Anders, Denis & Lake, Simone. (2022). Numerische Simulation des Formfüllprozesses und deren experimentelle Validierung. The International Journal of Advanced Manufacturing Technology. 120. 1–12. 10.1007/s00170-022-08888-9.

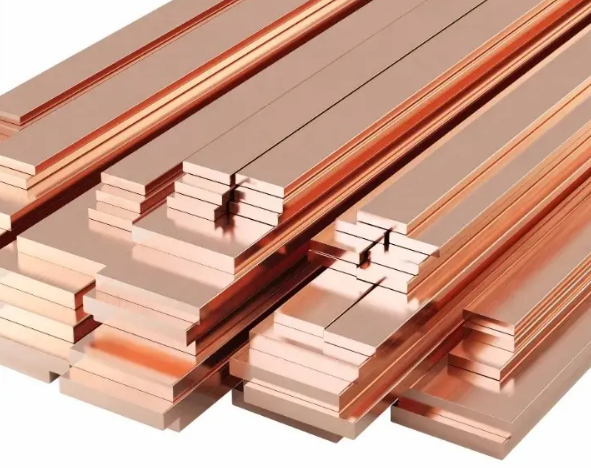

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento