Graphene Film: Strong Or Fragile?

Introduction

Graphene is a one-atom thick layer composed entirely of carbon. It is the subject of detailed scientific investigation given its unique atomic arrangement and potential technical applications. This article details the atomic structure, the measured tensile strength, the issues associated with increasing sheet size, and the progress made in scalable production methods.

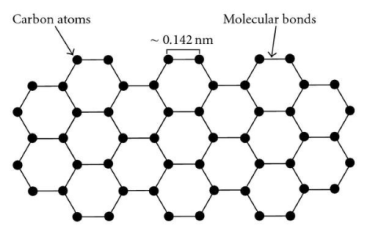

The Atomic Structure of Graphene

Graphene forms a hexagonal lattice of carbon atoms. A single layer has a thickness of approximately 1 nm. When multiple layers are stacked, the resulting material is known as graphite. In contrast, carbon fibres employ a different structural configuration that limits interlayer movement.

The Measured Tensile Strength of Graphene

Graphene is reported to exhibit high tensile strength. A study conducted by the Columbia University in 2008 attributed this strength to the covalent carbon–carbon bonds and the low incidence of microscopic defects. The theoretical tensile strength is measured at 42 N/m; however, practical use must account for defects such as cracks and scratches.

The Issue of Fragility

Graphene exhibits high intrinsic strength at the atomic scale. As the area of a graphene sheet increases, the likelihood of structural imperfections also increases. This reduction in effective strength poses a challenge for its application as a macroscale material. Production and handling processes therefore must implement measures that reduce defect occurrence.

Advances in Production Methods

Production techniques directly affect the performance characteristics of graphene. Chemical vapour deposition (CVD) uses a process in which carbon atoms are deposited onto a substrate. Consequently, the surface quality is improved although some imperfections may still be present. In 2011, silicon-based epitaxial growth technology was introduced, and it has been evaluated for large-scale production with improved surface consistency.

The Promise of Roll-to-Roll Manufacturing

On 01/09/2013, Graphene Frontiers introduced a roll-to-roll manufacturing technique for graphene. Although CVD produces consistent quality, it is expensive and impractical for commercial production. The approach by Graphene Frontiers has the potential to overcome these challenges, thereby yielding a mass production method that produces graphene meeting strict technical specifications.

Conclusion

The investigation demonstrates that graphene is not merely a subject of academic interest but holds potential for practical applications. Its hexagonal atomic structure and the challenges related to size-dependent fragility require further detailed research. Stanford Advanced Materials remains engaged in research to develop scalable and cost-efficient production methods, thereby assisting in making graphene a viable material for various industrial applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento