How Are Tungsten Alloys Used In The Aerospace Industry?

Tungsten Alloy is a type of alloy based on tungsten (85% ~ 99% tungsten content), with a small addition of Ni, Cu, Fe, Co, Mo, Cr and other elements. Its density reaches up to 16.5 ~ 18.75 g/cm³. Given that its chemical and physical properties meet established performance criteria, tungsten alloys are applied in several sectors. The aerospace industry utilises tungsten alloys extensively. However, how are tungsten alloys employed in the aerospace industry? This article provides an explanation.

How are tungsten alloys employed in the aerospace industry?

Tungsten Alloy Counterweight

In aerospace applications, counterweights are frequently fitted in confined spaces. Consequently, a higher mass per unit volume is required. Counterweight components of tungsten alloy are utilised to enhance control mechanism sensitivity and maintain aircraft operation within specified parameters.

Vibrations in the dynamic components of aircraft engines and propeller drive systems are not acceptable. Consequently, numerous counterweights may be incorporated to reduce or eliminate vibrations caused by mass imbalances in external rotating parts.

In addition, counterweights are employed in high-control propeller systems as a fail-safe mechanism. In flight, propellers are hydraulically managed to maintain the correct angle, while flight control surfaces such as the elevator, rudder and ailerons utilise counterweight components to optimise performance.

Tungsten Alloy Rotor Blade

In aerospace applications, tungsten alloys find use in a variety of counterweights for satellite and helicopter rotor blades, rockets and gyroscopic control systems. These materials are also employed in the cockpit to provide measurable vibration control. In fly-by-wire systems, a small quantity of tungsten alloy is integrated into the control stick to increase its inertia, thereby providing quantifiable control input for the elevator and ailerons.

Tungsten alloys are not restricted to counterweights and are also utilised in aircraft construction and maintenance. To mitigate vibrations produced by rivet guns, a Tungsten alloy counterweight is added to absorb external forces. Given that vibrations can adversely affect nerves, muscles and bones, potentially leading to carpal tunnel syndrome, numerous airlines currently employ vibration dampers made from tungsten alloys.

One principal requirement for the current aerospace industry is to increase long-haul passenger and freight transport capacity while concurrently reducing fuel consumption and emissions. Consequently, products and components manufactured from performance-specified tungsten alloys are required for future large civil aircraft, supersonic aircraft and other high-performance aviation vehicles.

Heat-resistant materials may lead to measurable improvements in propulsion systems, including aircraft and rocket turbine engines, as well as in the external thermospheric structures of hypersonic aircraft.

Materials that meet defined performance standards can reduce oil consumption and allow higher inlet temperatures in land-based gas turbines, thereby contributing to improved energy efficiency in aerospace. The materials must satisfy technical criteria including hot gas corrosion resistance, minimal thermal expansion, high creep resistance and reliable fatigue performance. Consequently, refractory metals from Stanford Advanced Materials are utilised in manufacturing combustion propulsion nozzles for satellites and other spacecraft.

Conclusion

The article provided detailed information regarding the application of tungsten alloys in the aerospace industry. For further information on tungsten and tungsten alloys, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of tungsten products with more than 20 years’ experience in the manufacturing and distribution of tungsten and tungsten alloys. The products are produced to meet specified research and production requirements. Accordingly, SAM is positioned to act as a supplier and partner for tungsten products.

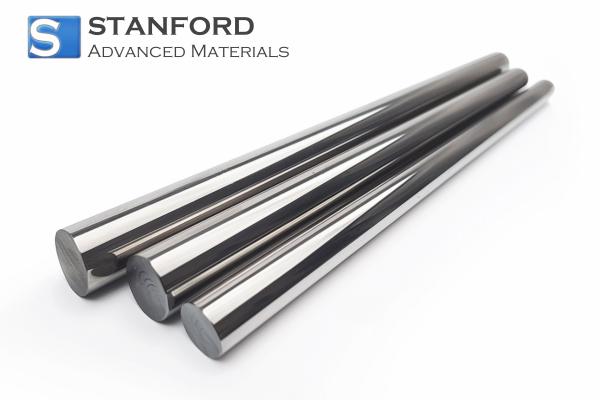

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento