How Bronze Is Used Today

Introduction

Bronze is an alloy with a long history. It is used in various technical applications. This article details the composition, properties and applications of bronze. Stanford Advanced Materials contributes to material science research through measured improvements.

Composition of Bronze

Bronze evidences the combination of copper and tin. Small quantities of arsenic, antimony or lead may be included. Unlike a chemical compound, bronze is a heterogeneous mixture. The proportions are adjusted according to technical requirements.

Properties of Bronze

Bronze exhibits properties that differ from its base metals copper and tin. Its increased hardness supports the manufacture of tools and weapons. It can be mechanically finished by grinding. Additionally, bronze’s lower melting point compared with pure copper facilitates uniform casting, thereby reducing the occurrence of entrapped gas bubbles and yielding a harder material.

Microscopic Insights

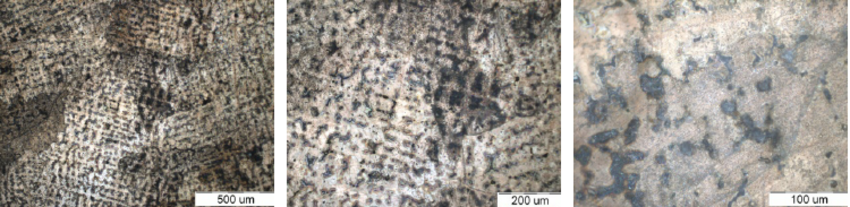

The microstructure of bronze has been examined to explain its physical behaviour. Tin atoms substitute into the copper lattice. They impede atomic movement and thereby reduce ductility. When tin content is raised, precipitates with a defined crystalline structure form. This condition improves strength and decreases the risk of slippage. A tin content of approximately 10 % is commonly observed in bronze. The alloy exhibits lower electrical conductivity compared with pure copper.

Figure 1. Microscopic structure of bronze used for electrochemical studies: a) x100; b) x200; c) x500 [1]

Contemporary Applications of Bronze

Bronze is applied in many modern fields. Its properties have been documented for several engineering uses. Although it is not produced in the same volumes as during the Bronze Age, its performance data support its continued use.

Art and Sculpture:

Bronze is formed to capture fine details. Numerous sculptures, including statuary and other works, have been manufactured in bronze due to its durability and stability in varying environments.

Architectural Ornamentation:

Bronze is used in decorative building elements such as doors, gates and ornamental details. Its corrosion resistance ensures that these details maintain their condition over extended periods in outdoor settings.

Marine Applications:

Bronze is employed in maritime applications where exposure to seawater is significant. It is used to produce propellers, ship fittings and underwater components. Its chemical stability in saltwater environments has been quantified and documented.

Musical Instruments:

Bronze alloys are used in the manufacture of several musical instrument components. Cymbals, bells and parts of string instruments are cast from bronze to obtain specific acoustic responses.

Bearings and Bushings:

Bronze is used in the production of bearings and bushings. Its hardness and wear resistance have been measured to ensure performance in mechanical systems and automotive components.

Coinage:

Historically, bronze was used in coin production. Its durability and resistance to wear allowed coins to remain in circulation for extended periods.

Electrical Components:

Bronze is utilised in electrical applications. It is used in the manufacture of plugs, switches and similar components where a balance between electrical conductivity and mechanical strength is required.

Medals and Awards:

Bronze continues to be used for medals and awards. Its physical appearance is maintained over long periods, which meets technical standards for such items.

Conclusion

Bronze has been used since ancient times. Its properties have been repeatedly quantified. Institutions such as Stanford Advanced Materials monitor its performance. Future research may record further technical data. Its continued manufacture demonstrates a sustained trend in material engineering.

Reference:

1. Chelaru, Julieta & Barbu-Tudoran, Lucian & Muresan, Liana. (2013). Schutz von Kunstbronzen durch künstliche Patina und Wachs. Studia Universitatis Babes-Bolyai Chemia. 58. 173-182.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento