LCP Film: Enabling 5G, Wearables, And Aerospace Advances

1 Introduction

Liquid crystal polymers (LCP) are high-performance polymers. When heated or dissolved, they show both fluidity and molecular ordering in their liquid crystalline phases. LCPs have rigid, rod-like molecular chain structures. They demonstrate high-temperature resistance, stable dielectric properties and dimensional stability. Since the 1970s, improvements in LCP materials have led to their use in electronics, telecommunications and industrial manufacturing.

LCPs can be categorised by their thermal and processing characteristics. Type I is used for high heat-resistant electronic components, Type II for antenna materials and Type III for connectors and sensors. LCP films exhibit specific electrical and mechanical properties. Their dielectric constant lies between 2.9 and 3.5. They absorb less than 0.04% water. They have a heat deflection temperature between 250 and 320 °C and tensile strengths of 150–300 MPa. Consequently, LCP films are used in high-speed and high-frequency electronics such as 5G mobile antennas, portable circuits and communication systems in aerospace, where material performance is critical.

2 Introduction to LCP Films

Liquid crystal polymers (LCP) provide fluid and molecularly ordered structures when heated or dissolved. They have a rigid, rod-like molecular chain structure and exhibit high-temperature resistance, stable dielectric properties and dimensional stability.

Since their development in the 1970s, LCPs have been adapted into various forms for electronics, telecommunications and industrial manufacturing. They can be divided into solvatochromic, thermochromatic and piezotropic liquid crystals. Thermochromatic liquid crystals are the most widely used.

Depending on product requirements, LCP is available in injection-moulded, film and fibre grades. Based on different synthetic monomers, LCP is divided into Types I, II and III. Type I LCP has high heat resistance, Type II offers both high heat resistance and processability, while Type III has lower heat resistance. Type I was commercialised in 1972; Type II and Type III were developed in 1984 and 1976, respectively. Type I is suited to electronic components, Type II to antenna materials and Type III to connectors and sensors.

LCP films remain stable at high speeds and frequencies. Their dielectric constant is between 2.9 and 3.5, making them suitable for high-speed and high-frequency applications. The low dielectric loss ensures effective performance in the GHz range. They absorb less than 0.04% water and have a low coefficient of thermal expansion of 10–17 ppm/°C. Given that they have a heat deflection temperature of 250–320 °C, performance remains consistent under extreme humidity and temperature fluctuations. Their tensile strength ranges from 150 to 300 MPa and elastic modulus from 10 to 25 GPa, thereby retaining stability in high-temperature environments. As a result of their low dielectric loss and measured mechanical properties, LCP films are widely used in modern electronic applications.

Fig. 1 LCP Films

3 Applications of LCP Films in Various Sectors

3.1 Flexible, Wearable Circuits

LCP films have excellent dielectric properties and act as effective electrical insulators. This function is important for portable electronic devices, as it prevents short circuits and signal interference. Their inherent flexibility enables compact and adaptable circuit designs. They can be integrated into clothing and accessories, thereby allowing the development of compact wearable technologies. Their low dielectric constant and minimal loss tangent ensure signal integrity, which is critical for high-frequency applications such as fitness trackers and smartwatches.

LCP films provide high tensile strength and flexibility. They can be bent and stretched without compromising structural integrity. The low weight of LCP films also contributes to user comfort. Devices that remain compact and unobtrusive are preferred by users.

LCP films are processed at high speeds, thereby enabling the production of detailed and complex geometries. This capability benefits manufacturers who wish to develop innovative wearable technologies. The films exhibit high thermal resistance and maintain performance over a wide temperature range. They are resistant to a variety of chemicals, including sweat and other body fluids, thereby withstanding direct contact with such substances.

Fig. 2 Flexible Wearable Circuit

3.2 5G Mobile Antenna

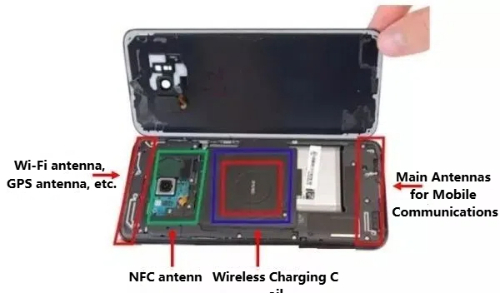

LCP films are increasingly used in 5G mobile antennas given that their electrical properties meet the demands of high-frequency communication. Their low dielectric constant helps reduce signal loss at high frequencies. This reduction is critical for 5G applications operating in millimetre-wave bands. The low loss tangent improves signal integrity, thereby allowing a higher proportion of the transmitted signal to reach its target. LCP antennas can be designed to support broad bandwidths, thereby enabling access to multiple frequency bands simultaneously. They can be integrated into printed circuit boards with minimal adjustment, thereby aiding efficient assembly and performance. The thin profile of LCP films permits the creation of compact antennas suitable for modern smartphones that prioritise a slender design. This compact design also contributes to the overall appearance of the device.

LCP films maintain their characteristics over a wide range of temperatures. Their thermal stability is important for 5G antennas that may generate heat during operation. Maintaining performance under variable temperatures is essential for dependable operation. Their flexibility and stability allow the production of lightweight, compact antennas that integrate into mobile devices without excessive space requirements. The films do not deform during either manufacturing or use. They are also resistant to moisture and chemicals, which is important for devices exposed to varying environmental conditions. Consequently, their performance remains steady throughout the service life of the device.

High-volume processing of LCP films ensures consistent quality, thereby providing a cost-effective option for manufacturers producing 5G smartphones in large quantities.

Fig. 3 Internal Antenna of a Mobile Phone

3.3 Large Aircraft High-Frequency Antenna

LCP films are used in high-frequency antennas for large aircraft given their favourable electrical properties. Their low dielectric constant reduces signal losses, thereby permitting efficient transmission of high-frequency signals essential for modern aircraft communication systems. The low loss tangent maintains signal integrity with minimal distortion. LCP antennas can support a broad frequency range, thereby accommodating the multiple communication channels needed for navigation, air traffic control and passenger connectivity. This capability improves overall communication efficiency.

LCP films function in extreme temperatures typically encountered in aviation. Their performance remains consistent over a wide temperature range. Their flexibility and strength enable the construction of lightweight antennas that integrate into the aircraft structure, thereby contributing to fuel efficiency. They can be integrated into existing RF systems without extensive redesign, thereby simplifying upgrades or replacements of conventional antenna materials. High-volume production of these antennas ensures consistent quality, thereby offering a cost-effective solution for aircraft RF systems.

LCP films are impact-resistant and withstand vibrations during flight. They are resistant to moisture and chemicals, which is essential for aircraft operating under variable weather conditions. Their low weight minimises additional burden on the aircraft, thereby benefiting fuel efficiency.

Fig. 4 High-Frequency Antenna

3.4 5G Millimetre-Wave Radar Communication

5G millimetre-wave radar communication uses the millimetre-wave frequency band (typically between 30 GHz and 300 GHz) for high-speed data transmission. Millimetre-wave bands provide a wider bandwidth, and 5G can support data rates exceeding 10 Gbps. Such rates are important for applications that transmit large volumes of data, for example high-definition video streaming, virtual reality (VR) and augmented reality (AR). These applications impose increased material requirements, and LCP materials meet these by maintaining low dielectric constants and low losses.

LCP films are being considered for 5G millimetre-wave radar communication given their stable electrical characteristics, thermal stability and mechanical strength. They have extremely low dielectric constants and low dielectric losses. Low dielectric losses reduce signal attenuation, thereby improving transmission efficiency. LCP films retain their stable electrical properties at high frequencies, thereby making them applicable in the 30 GHz to 300 GHz range required for millimetre-wave radar systems.

The thermal stability of LCP films allows operation in high-temperature environments without loss of performance. This factor is important for 5G communication base stations and millimetre-wave devices. LCP films withstand repeated thermal cycling, thereby ensuring consistent performance in harsh conditions. They also have high mechanical strength and toughness, thereby resisting physical damage and environmental stresses. Their flexibility permits the production of thinner antennas and circuits, thereby aiding higher integration and reduced weight in millimetre-wave radar devices.

In the manufacture of millimetre-wave antennas, LCP film is used as the dielectric material. Its low dielectric constant contributes to increased antenna gain and radiation efficiency. Given that LCP films perform well at high frequencies and can be processed efficiently, they are also used to produce array antennas for 5G communication. Furthermore, LCP films are used as encapsulation materials in millimetre-wave RF devices to protect electronic components from external influences.

Fig. 5 Communication Radar Base Station 5G Device Signal Transmission

3.5 5G Base Station Flexible Transmitter Unit

LCP films exhibit a low dielectric constant and a low dielectric loss factor. They are used for the transmission of high-frequency signals in the millimetre-wave range. Consequently, signal losses during high-speed and high-frequency transmission are reduced. In the antenna arrays and transmission channels of 5G base stations, LCP film is employed as a flexible circuit material to optimise transmission paths for high-frequency signals. This use results in improved transmission speed and signal stability, especially in the connection and signal modulation circuits within the antenna units.

LCP films offer excellent flexibility and mechanical properties. They retain structural integrity when bent or stretched. Their thin and durable nature permits processing in multiple layers without functional impairment. These characteristics meet the miniaturisation requirements of 5G base station modules, particularly in micro and nano base stations. Reduced thickness and weight simplify the installation of base station equipment in constrained locations such as flats on high-rise buildings or installations on street lamp columns, thereby extending 5G signal coverage.

Fig. 6 5G Base Station

4 Conclusion

In summary, LCP films display measured dielectric properties, defined mechanical strength, thermal stability and resistance to environmental influences. They provide a versatile solution for various high-performance applications. LCP films are used in flexible circuits, 5G mobile antennas, RF systems for aerospace and millimetre-wave radar communication, thereby preserving high-frequency signal integrity, enabling device miniaturisation and supporting flexible circuit designs. With increasing demand for high-speed, high-capacity and resilient technologies, LCP films deliver the necessary material properties for modern electronics, telecommunications and industrial systems.

Stanford Advanced Materials (SAM) is an important supplier of high-grade LCP films. They support these critical applications with reliable material solutions.

Further reading:

Main-chain liquid crystalline polymers for optical applications

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento