Liquid Crystal Polymer (LCP) Films In The Electronics Industry

1 Introduction

Liquid Crystal Polymer (LCP) is a class of high-performance polymers that exhibit liquid crystalline behaviour when heated or dissolved in solvents. This property results in a combination of fluidity and molecular order, and the material demonstrates measured thermal resistance, dielectric properties and dimensional stability.

Characterised by a rigid rod-like molecular structure, LCPs show a tightly packed molecular organisation with significant intermolecular forces. These features contribute to high-temperature performance, water absorption typically below 0.04% and predictable flow behaviour during processing. Since the development of these materials in the 1970s, LCPs have been categorised into Type I, II and III; each type has a distinct structural composition and thermal behaviour suitable for various electronics, telecommunications and industrial manufacturing applications.

Among LCP products, LCP films are used in applications that require stability under high-speed and high-frequency conditions, notably in electronic packaging and communication systems.

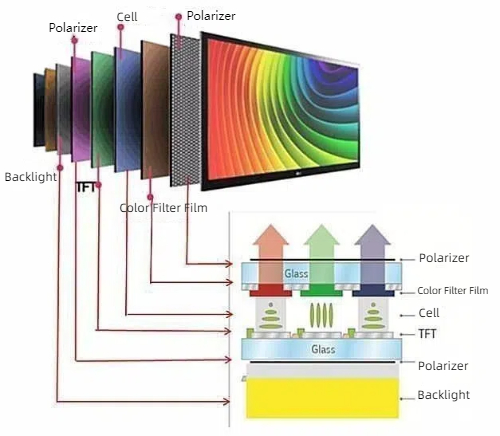

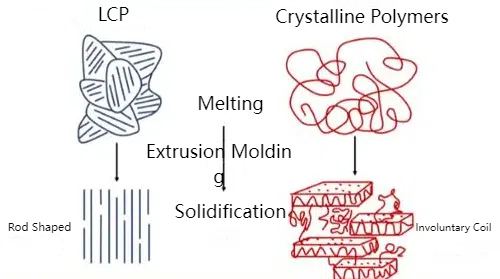

Fig. 1 Principle of Liquid Crystal Display

2 Introduction to LCP Film

2.1 What is LCP Film?

Liquid Crystal Polymer (LCP) is a macromolecule that can exist in a liquid crystalline state after being heated or dissolved by a solvent. When subjected to elevated temperatures or dissolved conditions, the rigid structure of the polymer changes to a more fluid state while preserving the molecular orientation and order. As a result, the material exhibits both liquid behaviour and an orderly molecular arrangement. In terms of structure, LCPs possess a rod-shaped molecular chain that can align in a high degree of orientation. The close stacking and strong intermolecular forces lead to high high-temperature resistance, a low water absorption rate and predictably high flow behaviour during processing.

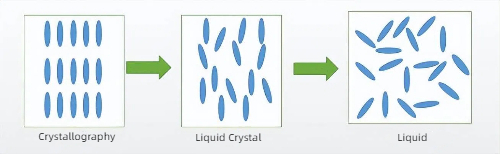

Fig. 2 Molecular Structure of Different States of Matter

2.2 Development History of LCP Film

The production of Liquid Crystal Polymers (LCPs) has been documented since the early 1970s. Various types of LCP were introduced during this period with research and development undertaken in several countries.

- Type I LCP: The first commercialised LCP, referred to as Ekonol, was developed in the United States in 1972. It was synthesised from monomers such as p-hydroxybenzoic acid (PHB), bisphenol A (BP) and terephthalic acid (TPA), resulting in a rigid molecular structure and a heat distortion temperature between 250℃ and 350℃. In 1979, Sumitomo Chemical in Japan independently developed the E2000 series, thereby contributing to the global availability of Type I LCP materials.

- Type II LCP: In 1984, Hoechst-Celanese introduced Type II LCP under the brand name Vectra. Type II LCP is composed of p-hydroxybenzoic acid (PHB) and 6-hydroxy-2-naphthoic acid (HNA), with a heat distortion temperature in the range of 180℃ to 250℃. In 1996, Polyplastics further developed this material under the brand name LAPEROS, extending its use in applications that require controlled mechanical properties.

- Type III LCP: Eastman Kodak introduced Type III LCP in 1976 and began production in 1986 under the brand name X-7G. This type, based on a flexible ester structure including HBA (p-hydroxybenzoic acid) and PET (polyethylene terephthalate), has a heat distortion temperature between 100℃ and 200℃. Its lower heat resistance has limited its application mainly to plastic connecting tubes and sensor components.

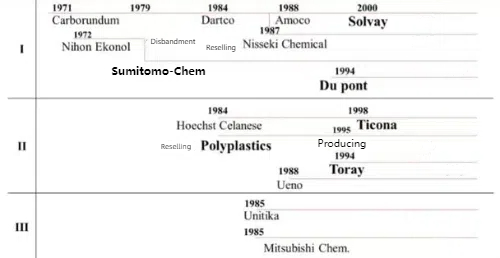

Fig. 3 Development History of LCP

2.3 Classification of LCP Films

LCP films can be classified according to their molecular characteristics, processing methods and end-use applications. This classification assists in the selection of an appropriate LCP material for various industrial applications.

2.3.1. Classification by Liquid Crystal Formation

Based on the conditions required for liquid crystal formation, LCPs can be divided into Lyotropic LCP (LLCP), Thermotropic LCP (TLCP) and Piezotropic Liquid Crystals.

- Piezotropic Liquid Crystals occur infrequently;

- Lyotropic LCPs are processed in solution and are typically employed in the production of fibres and coatings;

- Thermotropic LCPs are processed in the molten state and are available as injection moulding-grade, fibre-grade and film-grade materials. They are currently the most commonly used variant.

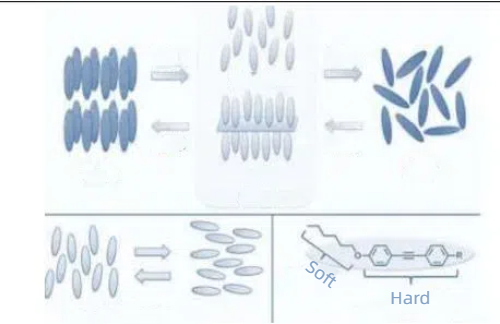

Fig. 4 Schematic Diagram of LLCP and TLCP

2.3.2. Classification by Product Grade

According to product specifications, LCP can be divided into injection moulding, film and fibre grades.

- Injection grade LCP is used in injection moulding to form intricate geometries by utilising the material’s fluidity at high temperatures. It offers a heat distortion temperature within the ranges indicated, chemical resistance and mechanical strength that meet the requirements of high-precision parts.

- Film grade LCP is manufactured to produce films with controlled heat resistance, electrical insulation properties and chemical stability. The low dielectric constant and low dielectric loss associated with these films facilitate high-frequency applications in the electronics and electrical industries.

- Fibre-grade LCP is processed into high-strength fibres with high tensile strength and modulus, and is used to reinforce composite materials. Its chemical stability and dimensional constancy are appropriate for applications requiring high-performance fibres.

2.3.3. Classification by Heat Resistance and Molecular Structure

Based on the variation in monomer synthesis and heat-related properties, LCP materials are divided into Type I, Type II and Type III.

- Type I LCP film is composed of p-hydroxybenzoic acid, bisphenol A and phthalic acid (PHB, BP and TPA). Its heat distortion temperature is between 250℃ and 350℃. However, the processing performance is relatively limited, and it is chiefly used in electronic components such as connectors.

- Type II LCP film is based on monomers p-hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid (PHB and HNA), with a heat distortion temperature between 180℃ and 250℃. This formulation balances heat resistance with processability and is particularly used for antenna materials.

- Type III is synthesised from HBA and PET with a heat distortion temperature between 100℃ and 200℃. The lower heat resistance of Type III restricts its current use.

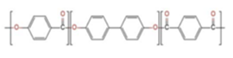

Table 1 3 Types of LCP

|

Types |

Heat Deformation Temperature |

Molecular Structure |

|

Type I |

250-350℃ |

|

|

Type II |

180-250℃ |

|

|

Type III |

100-200℃ |

|

3 LCP Film Product Characteristics

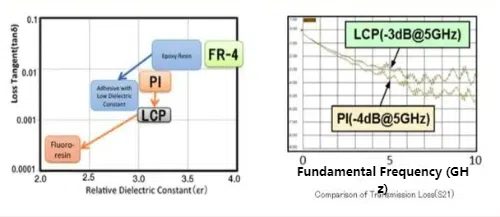

3.1 Stable Low Dielectric Constant and Dielectric Loss at High Speed and High Frequency

The dielectric constant quantifies the ability of a material to store electrical energy under an electric field. LCP films exhibit dielectric constant values typically between 2.9 and 3.5. A lower dielectric constant facilitates a faster electrical signal transit, thereby increasing the overall communication rate. Given that measurements are taken at frequencies above 10 GHz, these values help reduce signal delay and distortion during high-frequency transmission.

Dielectric loss represents the energy dissipated as heat when a material is subjected to an electric field. LCP films record dielectric loss values in the range of 0.002 to 0.004, which indicates minimal energy loss during signal transmission at high frequencies. Consequently, signal attenuation is reduced, maintaining data integrity over extended distances or at elevated speeds. These properties enable LCP films to operate over a broad temperature range (from -50°C to over 250°C) while preserving electrical performance.

The measured low dielectric constant and low dielectric loss of LCP films underpin their use in high-speed, high-frequency signal transmission.

Fig 5 LCP Reduces High-Frequency Transmission Losses

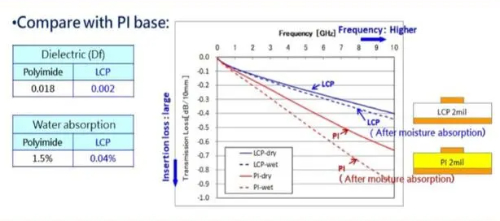

3.2 Low Water Absorption and Low Thermal Linear Expansion Coefficient

LCP films are applied in high-precision electronics and communication devices owing to their low water absorption and limited linear expansion under thermal variations. These characteristics assist in maintaining performance in environments where humidity and temperature fluctuate.

Water absorption quantifies how much water a material can absorb from its surroundings. LCP films exhibit water absorption below 0.04%, thereby ensuring that moisture has little effect on the electrical properties. This low rate also means that physical dimensions remain consistent in varying humidity levels. Consequently, LCP films are suitable for applications where moisture resistance is critical.

The Coefficient of Thermal Expansion (CTE) indicates the extent to which a material expands with temperature change. LCP films typically have a CTE in the range of 10 ppm/°C to 17 ppm/°C. This low thermal expansion assists in maintaining dimensional accuracy even during significant temperature changes, particularly when compared with materials such as copper in high-frequency electronic applications.

Fig. 6 Comparison of Transmission Loss Before and After Moisture Absorption Between LCP Substrate and PI Substrate

3.3 High-Dimensional Stability and Barrier Properties

LCP films are used in applications requiring precise dimensional stability and effective barrier performance against gases, moisture and chemicals.

The stability in dimensions is a result of the organised molecular structure, which maintains shape and size when subjected to heat or mechanical stress. The low CTE further ensures that the material exhibits minimal expansion or contraction during temperature fluctuations, even under conditions above 250°C. Such stability is particularly significant in heat-sensitive devices.

Furthermore, the molecular structure contributes to high tensile strength and resistance to impact. These attributes ensure that the material retains its dimensions under stress. In addition, LCP films possess effective barrier properties against gases such as oxygen, carbon dioxide and nitrogen. With water absorption remaining under 0.04%, moisture penetration is reduced. The chemical inertness of LCP films further allows prolonged exposure to corrosive agents without degradation. These properties make LCP films suitable in electronic devices and components that require controlled permeability and dimensional accuracy.

Fig. 7 The Molecular Structure of LCP underpins its Measured Performance in Comparison with Other Thermoplastic Materials

3.4 Heat Resistance and Hot/Cold Alternating Properties

The heat resistance and the ability to withstand alternating hot and cold conditions are critical for LCP films in electronic, communication and industrial applications. These properties ensure that the physical and electrical characteristics remain stable under extreme temperature variations.

LCP films display measured heat distortion temperatures between 250°C and over 320°C. This thermal stability allows the films to operate for extended periods in high-temperature environments with minimal physical deformation. In high-frequency circuits and 5G communication devices, LCP films maintain low dielectric constant and loss even at elevated temperatures. In addition, LCP films are self-extinguishing and can cease combustion rapidly when exposed to an ignition source.

Fig. 8 Heat Resistance of LCP Films as determined by their Liquid Crystalline Molecular Structure

LCP films also exhibit stable performance across cycles of high and low temperatures. The low CTE (typically between 10 ppm/°C and 17 ppm/°C) implies minimal dimensional changes during thermal cycling. This contributes to the long-term serviceability of components that undergo repeated heating and cooling cycles.

3.5 Mechanical Properties (High Strength, High Modulus)

LCP films are employed in environments that demand resistance to mechanical stress. The molecular chains, arranged in a liquid crystalline state, are aligned to provide resistance against tensile stresses. Measured tensile strengths are typically in the range of 150 MPa to 300 MPa. The materials are also lightweight, with densities around 1.4–1.6 g/cm³.

The films also show a high Young's modulus, typically between 10 GPa and 25 GPa. This characteristic ensures minimal elastic deformation under applied stress. The high flexural modulus contributes to resistance against bending forces, which is critical for applications such as flexible printed circuit boards and antennas. Furthermore, LCP films retain these mechanical properties at temperatures above 250°C and at low temperatures, making them suitable for aerospace and defence applications where repeated thermal cycling occurs.

Fig. 9 LCP is utilised in avionics as a consequence of its measured mechanical and electrical properties

Table 2. Key Properties of LCP (Liquid Crystal Polymer) Films

|

Property |

Values |

|

Dielectric Constant (Dk) |

2.9 – 3.5 |

|

Dielectric Loss (Df) |

0.002 – 0.004 |

|

Water Absorption |

< 0.04% |

|

Coefficient of Thermal Expansion (CTE) |

10 – 17 ppm/°C |

|

Operating Temperature Range |

-50°C to over 250°C |

|

Tensile Strength |

150 – 300 MPa |

|

Young's Modulus |

10 – 25 GPa |

|

Key Applications |

High-frequency applications, 5G communications, Flexible circuits, Aerospace |

4 Conclusion

LCP films are employed in high-performance applications owing to a combination of measured properties. They exhibit low dielectric constant and dielectric loss, water absorption below 0.04% and a low coefficient of thermal expansion, ensuring stable performance in controlled environments. In addition, LCP films provide dimensional stability, high strength and consistent behaviour under temperature fluctuations. These attributes support their application in high-frequency circuit boards, flexible circuits and precision electronic packaging. As electronic devices progress towards higher frequencies and greater miniaturisation, LCP films will continue to support such advancements.

Stanford Advanced Materials (SAM) remains a provider of high-quality LCP films, supporting critical applications with reliable material solutions.

Related Reading:

Main-chain Liquid Crystalline Polymers for Optical Applications

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento