Polyaramid Honeycomb: Stability, Manufacturing, And Applications

Polyaramid honeycomb structures are manufactured from high-strength, lightweight and dense core products composed primarily of aramid fibres such as Nomex®. These honeycomb cores are common in applications with a high composite material content – from interior components in aerospace to explosion protection panels in defence. This article provides a technical summary of their structures and primary uses in various sectors.

1. Introduction to Polyaramid Honeycomb Structures

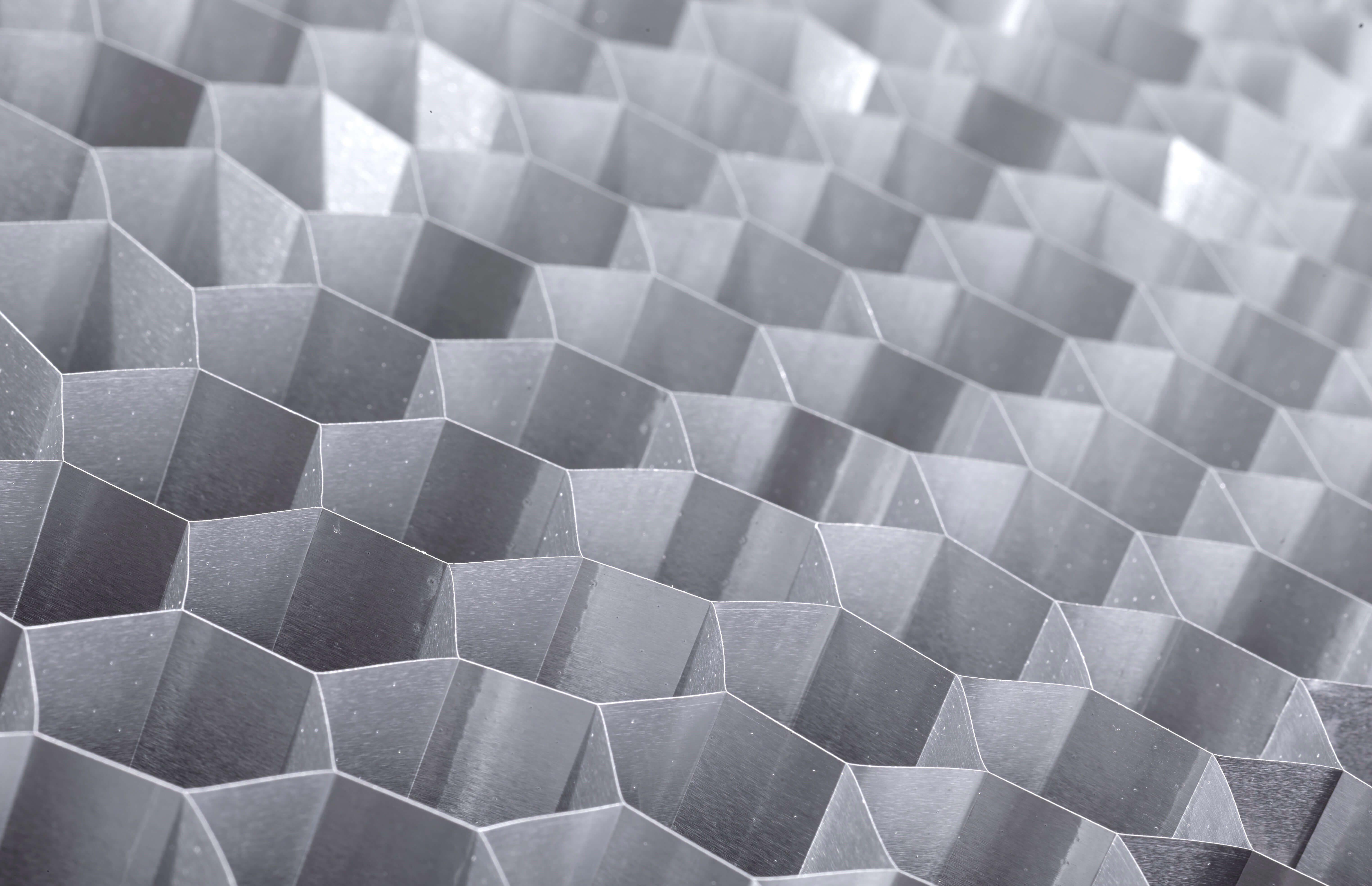

Polyaramid honeycomb cores are produced by expanding aramid fibres impregnated or coated with phenolic resin, typically Nomex® paper. The process creates a cellular structure with a hexagonal or elongated cell pattern, thereby replicating the load bearing behaviour of natural honeycombs. They are used as a core material in sandwich panels, in which thin, high-strength composite facings (e.g. carbon or glass fibre reinforced plastics) are adhesively bonded to both sides. The polyaramid core provides stiffness, energy absorption and insulation without adding significant weight. It is particularly suitable for weight-sensitive applications.

Fig. 1 Polyaramid Honeycomb Structure

2. Mechanical Properties of Polyaramid Honeycomb Cores

The mechanical properties of polyaramid honeycomb cores are one of their defining characteristics.

Their main properties are:

- High strength-to-weight ratio: Despite its low weight, the core can support large loads in both shear and compression.

- Fatigue resistance: Polyaramid honeycombs resist cyclic loads, thereby maintaining performance under long-term stress.

- Damage tolerance: In contrast to brittle core materials, polyaramid honeycombs undergo plastic deformation under strong impact, thereby reducing the risk of complete structural failure.

Given these properties, they are suitable for structural and semi-structural applications on both civil and military platforms.

3. Thermal and Chemical Stability of Aramid-based Honeycomb

Polyaramid honeycomb cores exhibit high chemical and thermal stability. They perform reliably in environments up to 180°C and maintain dimensional stability over a wide temperature range. They are employed in heat-resistant adhesive bonds due to their resistance to thermal degradation.

Chemically, they are resistant to moisture, solvents, fuels and acids. This is beneficial for applications in marine and humid environments. Their fire behaviour complies with requirements such as FAR 25.853 regarding flame, smoke and toxicity for aircraft interiors.

4. Comparison with Other Honeycomb Materials

Engineers compare honeycomb materials based on weight, strength, durability, corrosion resistance and cost. Polyaramid honeycombs perform well in these aspects:

- Compared with aluminium honeycombs: Although aluminium is stiffer and has better temperature resistance, polyaramid honeycombs are lighter, resistant to corrosion and better meet FST (Flame, Smoke and Toxicity) requirements.

- Versus thermoplastic honeycombs: Thermoplastic cores are less costly and recyclable; however, they typically do not provide the mechanical strength or the thermal stability required of aramid cores.

- Versus carbon/Kevlar honeycombs: Whilst carbon and Kevlar cores offer higher performance, they incur higher costs. Polyaramid honeycombs constitute an economically efficient choice.

These comparisons indicate that polyaramid honeycombs are applicable in various sectors. Further honeycomb products are available from Stanford Advanced Materials (SAM).

Fig. 2 Aluminium Honeycomb

5. Acoustic and Vibration Damping in Polyaramid Panels

Polyaramid honeycombs absorb sound and mechanical vibrations. As the core for sandwich panels, the material absorbs vibrational energy and functions as an acoustic barrier. In the transport sector – including aircraft cabins, train carriages and automotive interiors – reduced noise contributes to improved comfort and passenger satisfaction.

6. Applications of Polyaramid Honeycomb Cores

Sandwich Structures for Aerospace

Polyaramid honeycombs are extensively used in aircraft interiors such as floor panels, side walls, ceilings, overhead bins and partitions. They enhance safety and performance by providing flame retardance, reduced smoke generation and improved mechanical properties. The material reduces overall weight, thereby enhancing fuel efficiency and payload capacity.

Automotive Interior Applications

Aramid honeycombs are employed in vehicles as the core material for door panels, boot covers and headliners. They assist in meeting fuel efficiency targets by reducing vehicle weight while maintaining the necessary flammability standards. Their capacity to absorb energy further contributes to occupant protection during accidents.

Marine and Railway Panels

In maritime applications, the corrosion resistance of polyaramid honeycomb panels is advantageous. They are utilised in ship interiors, bulkheads and deck constructions. In rail transport, manufacturers use them to satisfy weight restrictions and stringent fire safety standards, particularly in high-speed trains and underground services.

Defence and Energy Absorption

Polyaramid honeycombs are implemented in armoured systems, explosion protection panels for vehicles and mobile protective structures where energy absorption is critical. Their low weight and plastic deformation under impact help absorb and dissipate energy.

UAV and Drone Structures

Unmanned Aerial Vehicles (UAVs) and drones require lightweight and strong structures. Polyaramid honeycomb cores are employed in wings, fuselage shells and control surfaces. They enable extended flight endurance and manoeuvrability without compromising structural integrity.

7. Conclusion

Both in aerospace and in defence, polyaramid honeycombs meet technical requirements in mechanical, thermal and acoustic domains. They serve as an important core material in composite engineering. As new processing technologies and resin systems become available, polyaramid honeycomb material will continue to support lightweight structural applications.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento