Properties & Applications Of Nano Zirconium Carbide

Zirconium carbide is a hard material with a high melting point and is an excellent fire‐resistant material for elevated temperatures. Nano‐zirconium carbide is a form of conventional zirconium carbide. Given its measured physical and chemical properties, nano‐zirconium carbide is widely used in industrial production. In this article, we examine the properties and applications of nano‐zirconium carbide.

Properties and Applications of Nano‐zirconium Carbide

Properties of Nano‐zirconium Carbide

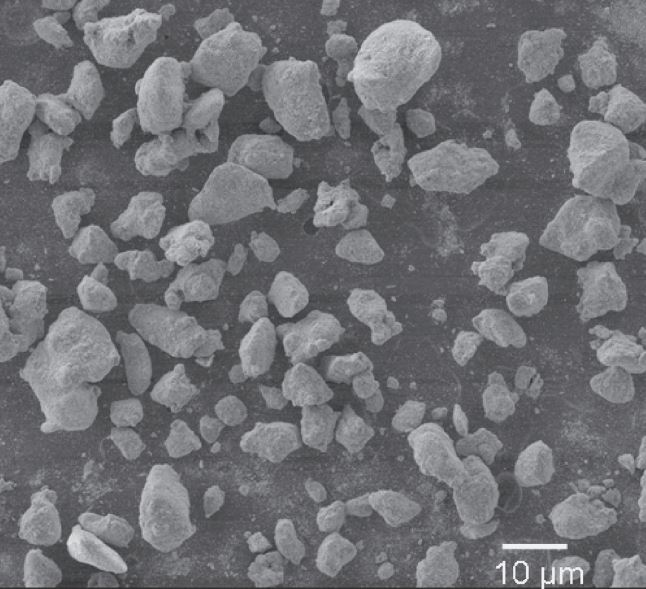

- Nano‐zirconium carbide is characterised by high purity, small particle size, uniform distribution, a large specific surface area, high surface activity and low bulk density.

- It possesses properties such as high‐temperature resistance, oxidation resistance, high strength, high hardness, high thermal conductivity and toughness.

- Nano‐zirconium carbide is used as a high‐temperature structural material owing to its high melting point, high strength and corrosion resistance. It is capable of efficiently absorbing visible light, reflecting ultraviolet light and storing energy.

Applications of Nano‐zirconium Carbide

- Application of Nano‐zirconium Carbide in Thermally Insulating and Temperature‐Regulating Textiles

Nano‐zirconium carbide efficiently absorbs visible light and reflects infrared radiation. It can absorb wavelengths under 2μm and reflect wavelengths over 2μm. Consequently, through energy conversion, it prevents heat loss from the human body.

- Application of Nano‐zirconium Carbide in Fibres

When the ZrC content in the fibre reaches 0.02% by weight, the fibre attains optimal near‐infrared absorption performance. The near‐infrared absorption exhibited by ZrC in the outer layer of the fibre surpasses that in the core layer.

- Application of Nano‐zirconium Carbide in High‐Temperature Coatings

The melting point of nano‐ZrC is 3 540℃. ZrC ceramics exhibit measured mechanical properties and high temperature resistance under elevated temperatures and in severe environments. Consequently, they are used in aerospace applications.

- Application of Nano‐zirconium Carbide in Cemented Carbide

ZrC is a high‐temperature material with a high melting point, high strength and corrosion resistance. The strength and corrosion resistance of sintered carbide containing nano‐ZrC are significantly enhanced.

- Application of Nano‐zirconium Carbide in Metallic Coating Materials

A porous ZrC coating with low density exhibits thermal load tolerance and insulation properties, thereby serving as an insulating material; in contrast, a dense ZrC coating with high density demonstrates penetration resistance and is employed as a protective layer.

- Application of Nano‐zirconium Carbide in the Nuclear Industry

Nano‐zirconium carbide exhibits high temperature resistance, high hardness, a low thermal neutron absorption cross‐section and radiation resistance. It is used as a material for coating nuclear fuel particle barriers.

- Nano‐zirconium Carbide is Used as an Abrasive

Nano‐ZrC has a Mohs hardness of 8–9 and exhibits thermal conductivity. It can serve as a substitute for conventional abrasives.

Conclusion

We appreciate your reading of this article and expect that it provides a clearer understanding of the properties and applications of nano‐zirconium carbide. Should you require further information regarding nano‐zirconium carbide, please visit Stanford Advanced Materials (SAM) for additional details.

As a leading supplier of zirconium carbide products, SAM has over two decades of experience in the production and sale of zirconium carbide powder and nano‐zirconium carbide powder. Consequently, SAM may serve as your designated zirconium carbide supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento