SAM Showcases HBN For Thermal Management In Power Electronics

Introduction

Stanford Advanced Materials (SAM), an established supplier of high‐performance ceramics and technical materials, presents data regarding the increased usage of its high‐purity hexagonal boron nitride (h-BN) in addressing thermal management issues in electronic high‐voltage systems. The material is employed in applications such as electric vehicles, semiconductor devices and power modules.

Dr. Samuel R. Matthews, Chief Materials Officer at SAM, explained,

"Hexagonal boron nitride offers a combination of thermal conductivity and electrical insulation that meets the requirements of advanced power electronics. In a recent case, a global client improved the efficiency of heat dissipation by 40% after integrating our BN plates. SAM is therefore committed to delivering quantifiable performance and sustainability benefits."

Case Study: Thermal Management in Power Electronics with Hexagonal Boron Nitride

-Challenge: Thermal Management

A global manufacturer of silicon carbide (SiC) power modules approached SAM with a critical problem. The existing thermal interface materials failed at high temperatures. The modules, designed for inverters in electric vehicles and industrial motor drives, were routinely operated at temperatures above 300 °C. Under these conditions the client observed:

- Rapid degradation of the thermal interface materials

- Insufficient dielectric insulation at voltages above 3 000 V

- Delamination and distortion of ceramic substrate stacks

- Reduced heat dissipation efficiency, resulting in localised overheating

The engineering team required a material that provided both high thermal conductivity and electrical insulation, and was stable up to at least 900 °C in air. The material was also required to be available in plates measuring 50 mm × 50 mm × 1 mm, with tight dimensional tolerances and suitable for machining in customised module designs.

[1]

[1]

--SAM’s Solution: Hexagonal Boron Nitride Grade A

After reviewing the application requirements, Stanford Advanced Materials recommended its plates made from hexagonal boron nitride Grade A, a high‐purity ceramic developed for extreme thermal and electrical conditions. In contrast to conventional interfacial materials, h-BN provides a quantifiable combination of thermal conductivity and electrical insulation, thereby meeting the demands of high‐voltage applications.

The product specifications are as follows:

|

Property |

Specification |

|

Purity |

99.5% |

|

Thermal Conductivity |

~35 W/m-K (in-plane) |

|

Electrical Specific Resistivity |

>10¹³ Ω-cm |

|

Dielectric Strength |

>3.5 kV/mm |

|

Operating Temperature |

900 °C in air, 1800 °C in inert gas |

|

Density |

~2.1 g/cm³ |

|

Delivered Dimensions |

50 mm × 50 mm × 1.0 mm |

|

Machinability |

Meets CNC processing requirements |

SAM also provided support for customised machining and vacuum-sealed packaging, thereby preserving the material’s integrity during shipping and storage.

-Implementation and Results

The manufacturer integrated the h-BN plates into its power module assembly, using them as the thermal interface between the SiC chips and the copper heat spreaders. Subsequent tests and field data indicated improvements as follows:

- A 40% improvement in heat dissipation efficiency compared to the previous interface material

- A reduction in hotspot peak temperatures by 20 °C under full load

- No dielectric breakdown after 1 000 thermal cycles between 25 °C and 300 °C

- A consistent flatness of the plate within ±0.02 mm, thereby mitigating mechanical stresses during bonding

- A reduction in integration time, given the confirmed machinability

Following these results, the client converted its entire range of high-voltage SiC modules to SAM’s h-BN solution and initiated a second phase of material evaluation for h-BN coatings in other thermally critical components.

What is Hexagonal Boron Nitride?

Hexagonal boron nitride (h-BN) is a synthetic ceramic compound with a structure that resembles that of graphite. Unlike graphite, which is electrically conductive, hexagonal boron nitride functions as an effective electrical insulator. This results in h-BN being capable of both high thermal conductivity and high electrical resistance – two attributes that are rarely encountered concurrently.

High-purity forms, particularly those with a BN content exceeding 99%, are employed in high-technology manufacturing, electronics, aerospace and energy sectors. The principal physical properties of high-purity hexagonal boron nitride are:

|

Features |

Values |

|

Thermal Conductivity |

~30-50 W/m-K (in-plane) |

|

Electrical Resistance |

>10¹²-10¹³ Ω-cm |

|

Dielectric Strength |

>3.5 kV/mm |

|

Operating Temperature |

Up to 1000 °C in air and up to 1800 °C in inert atmospheres |

|

Low Friction Coefficient |

~0.15 |

|

Density |

~2.1 g/cm³ |

|

Machinability |

Suitable for machining, comparable to that of soft metals |

Applications of Hexagonal Boron Nitride

The thermal and electrical properties of hexagonal boron nitride render it valuable across several sectors. It is available in various forms – powder, sheets, coatings and composites – each addressing specific requirements.

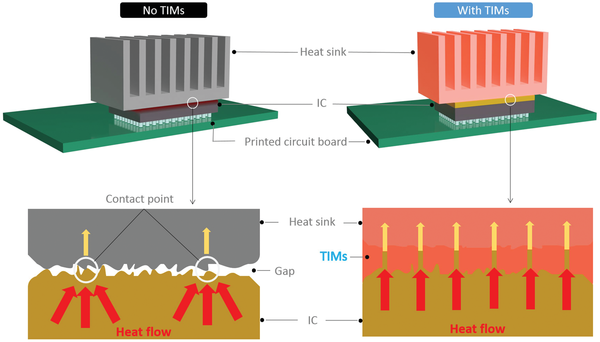

- h-BN is used as a thermal interface material in SiC/GaN power modules, LEDs and high-frequency circuit boards. It contributes to heat dissipation while providing electrical insulation, and it is also applied for EMI shielding and as a heat spreader.

- Due to its stability, h-BN is used to line crucibles for metal processing, retaining temperatures above 1 700 °C in vacuum or inert environments.

- Employed as a dry lubricant, h-BN withstands pressure and heat; this renders it suitable for aerospace and vacuum systems.

- In skincare and make-up applications, h-BN imparts a smooth feel, controls oil and is gentle on the skin.

- It increases the strength, heat resistance and thermal conductivity of composites, and it supports 3D printing applications in aerospace and defence.

Conclusion

Hexagonal boron nitride addresses advanced thermal and electrical challenges in power electronics. With a wide range of ceramic materials and application-specific technical support, Stanford Advanced Materials remains a reliable partner for engineers working at the limits of performance and reliability.

Reference:

[1] Wang, Zhengfang & Wu, Zijian & Weng, Ling & Ge, Shengbo & Jiang, Dawei & Huang, Mina & Mulvihill, Daniel & Chen, Qingguo & Guo, Zhanhu & Jazzar, Abdullatif & He, Ximin & Zhang, Xuehua & Xu, Ben. (2023). A Roadmap Review of Thermally Conductive Polymer Composites: Critical Factors, Progress, and Prospects. Advanced Functional Materials. 33. 10.1002/adfm.202301549.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento