Solubility Behavior Of Yttrium In Mg-Y Alloys And Recommended Processing Route

Magnesium-Yttrium (Mg-Y) Alloys have attracted increased attention in lightweight applications because of their excellent strength-to-weight ratio and thermal stability. Mg-1 at.% Y is a typical composition for examining yttrium solubility and its effect on alloy performance. This article explains the solubility behaviour of yttrium in magnesium, outlines key processing parameters and presents a method to produce a fully dissolved Mg-Y solid solution.

1. Alloy Composition and Solubility Requirements

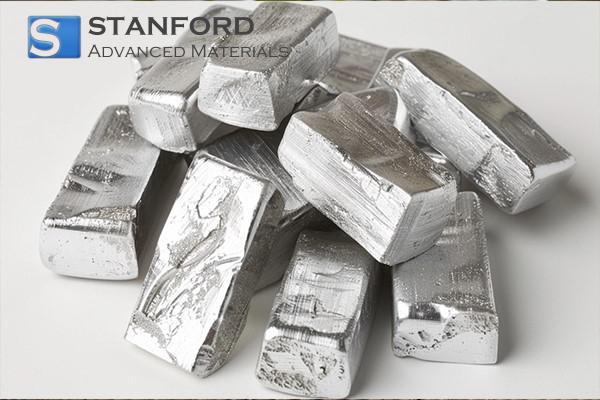

The base alloy is Mg-1 at.% Y. It is produced from high-purity magnesium (≥99,99% pure). Yttrium, a rare earth element with limited solubility at room temperature, can dissolve into the α-Mg matrix at elevated temperatures. Achieving complete solubility is crucial for mechanical performance and suppresses the formation of intermetallic compounds such as Mg₂₄Y₅ or Mg₄₂Y₅ that cause embrittlement.

The goal is to create a uniform solid solution in which yttrium is fully dissolved in the α-Mg matrix. This process improves corrosion resistance, thermal stability and strength while preventing unwanted precipitations during processing or service.

2. Mechanism of Yttrium Solubility in Magnesium

Yttrium dissolves in magnesium via a standard substitutional mechanism. At temperatures above 500 °C, yttrium atoms occupy positions within the magnesium matrix.

Given the narrow solid solubility range of yttrium in magnesium at lower temperatures, precise control of the thermal profile is required. Temperature is the primary driving force for dissolution, while time and atmosphere serve as supporting factors. Maintaining the alloy at the required temperature allows uniform diffusion. The cooling phase must be carefully controlled to prevent precipitation of secondary yttrium-rich phases. Inert or semi-inert protective gases are necessary to prevent oxidation during melting and heat treatment, thereby ensuring chemical stability.

3. Recommended Processing Procedure

To fully dissolve yttrium in magnesium, the following processing steps are recommended.

Melting and Alloying

The alloy is prepared by mixing high-purity magnesium with a Mg-25 wt% Y master alloy. The melting process is carried out in an induction furnace at approximately 760 °C under a protective gas atmosphere. A mixture of 99% CO₂ and 1% SF₆ is used. This gas mixture shields the melt from oxygen and prevents oxidation of the rare earth. The mould is preheated to between 200 °C and 300 °C. Preheating improves metal flow and reduces thermal gradients during casting.

Casting and Cooling

Once the alloy is molten and homogenised, it is cast under a continuous protective gas flow into a mould. The cooling rate is carefully controlled. A rapid cooling rate may cause thermal stress, whereas slow cooling could allow precipitation of intermetallic compounds. A moderate cooling profile ensures phase stability and grain refinement.

Solution Treatment and Quenching

After casting, the alloy undergoes solution treatment at 525 °C for 15 hours. This treatment dissolves any remaining yttrium-rich particles in the magnesium matrix. A protective atmosphere is maintained to preserve surface quality and internal cleanliness. The treated alloy is then quenched in hot water at approximately 70 °C, thereby preventing the precipitation of secondary phases during cooling.

4. Operational Flexibility and Practical Considerations

The recommended parameters may be adjusted according to equipment constraints or production scale. Operators must ensure uniform temperature distribution, strictly control the atmosphere and adhere to precise timing at each stage. Gas release, local overheating or delayed quenching may result in inclusions or the precipitation of intermetallic compounds, which in turn adversely affect alloy quality.

The design of the casting mould and the stirring of the melt are also important. Minimising turbulence during casting and using smooth-walled crucibles help to maintain the chemical homogeneity of the final product.

References

Several peer-reviewed studies and technical articles support the described process and solubility mechanism:

-

Effects of Y Additions on the Microstructures and Mechanical Behaviours of as-Cast Mg-xY-0.5Zr Alloys, Advanced Engineering Materials, 2022.

-

Microhardness and In Vitro Corrosion of Heat-Treated Mg-Y-Ag Biodegradable Alloy, PMC, 2017.

-

Effect of Solution Treatment Time on Microstructure Evolution and Properties of Mg-3Y-4Nd-2Al Alloy, Materials (MDPI), 2023.

-

Thermodynamic and Microstructural Evolution in Mg-Y Binary Alloys during Solidification, Wiley Online Library, 2021.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento