Super Performance Of Niobium In Superconducting Applications

Many years ago, researchers discovered that the chemical properties of certain materials can change sharply, resulting in superconductivity with negligible electrical resistance when the temperature is near absolute zero. This performance temperature is defined as the critical temperature. The critical temperature varies among materials.

It is well known that achieving ultra‐low temperatures requires significant resources, thereby increasing costs. The closer the temperature approaches absolute zero, the higher the cost incurred. In the case of superconducting materials, a higher critical temperature is advantageous. Many elements exhibit superconductivity, and Niob is one of those with one of the highest critical temperatures. A niobium alloy exhibits a critical temperature between 18.5 and 21 K, which makes it one of the principal superconducting materials.

Researchers conducted an experiment in which a metal ring made of Niob, cooled to its superconducting state, was supplied with an electrical current. The current was then disconnected and the apparatus sealed and maintained at a low temperature. After 2 ½ years, the instrument was reactivated and it was noted that the current in the niobium ring continued to flow, with the current level nearly identical to the initial supply.

The experiment demonstrates that superconducting materials experience minimal electrical losses. Consequently, the use of a superconducting transmission cable improves energy transfer efficiency because the absence of electrical resistance prevents energy loss.

A superconducting magnetic wheel has been developed for a high‐speed magnetic levitation system. The superconducting magnet causes the train to levitate approximately 10 centimetres above the rail, thereby eliminating friction between the two and reducing movement resistance. With an engine power of only 100 horsepower, the train, which carries 100 passengers, can achieve speeds exceeding 500 kilometres per hour.

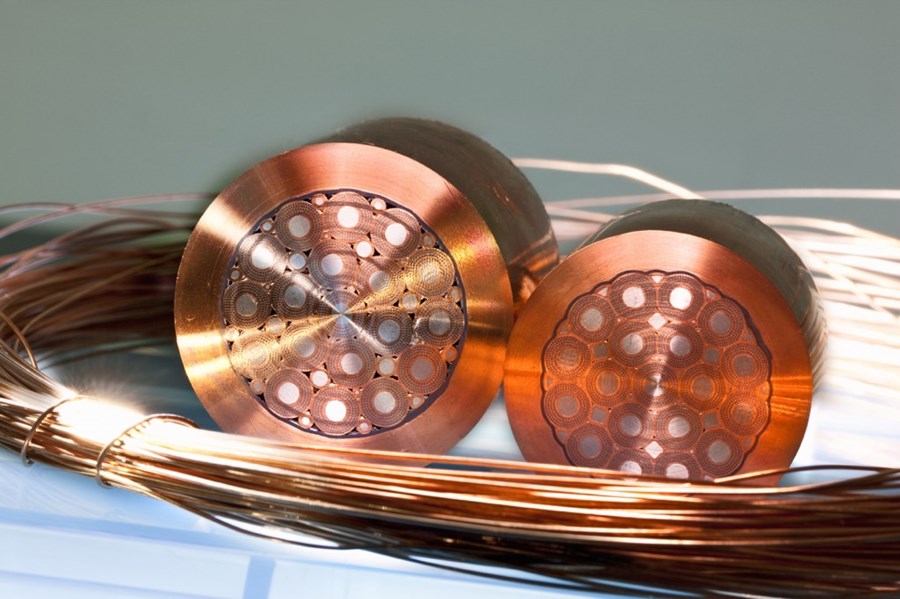

If a 20 kilometre-long band composed of Niob and tin is wound around a rim with a diameter of 1.5 metres, the winding can generate a stable magnetic field. This magnetic field is capable of lifting an object weighing 122 kg and maintaining its levitation. Given that this magnetic field can be employed in a controlled thermonuclear fusion reaction, it is feasible to supply a substantial volume of low-cost and nearly inexhaustible energy.

Read more: The role of Niob in superconducting materials

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento