What Can We Expect To Acquire From Tantalum Carbide In The Future?

Tantalum Carbide is a type of transition metal carbide with a black or dark brown colour. It belongs to the cubic crystal system. Tantalum carbides are used in cutting tools and are sometimes added to tungsten carbide alloys. Their melting points can reach approximately 3880 °C, which is among the highest for binary compounds.

Tantalum carbide exhibits physical and chemical properties. It has high hardness and a high melting point. It shows notable electrical conductivity and thermal shock resistance. It resists chemical corrosion and oxidation. It also has catalytic properties. These characteristics lead to its use in industry and the military sector.

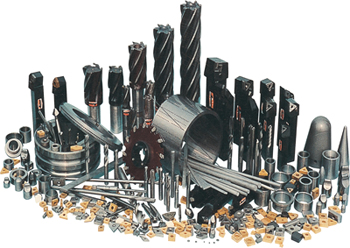

Tantalum carbide is often used as an additive in hard alloys. Its primary function is to improve the high-temperature strength of cemented carbide and tungsten carbide particles. In cutting tools, it is applied as a hard coating to increase chemical corrosion resistance and wear resistance of the substrate. In military applications, it is used as a coating for turbine blades of jet engines and rocket nozzles, thereby improving erosion resistance and extending service life. Its electrical conductivity permits use in electrode materials. It can be processed into complex shapes by wire cutting. It is also employed as a second-phase particle in metal matrix composites. It is used in aerospace, metallurgy, construction materials, electrical energy, hydropower, mining and other sectors.

Additionally, tantalum carbide is applicable in powder metallurgy, cutting tools, precision ceramics, chemical vapour deposition and as a wear-resistant alloy additive to enhance alloy toughness. The sintered body of tantalum carbide exhibits a golden colour; it can be used in watch jewellery. In combination with Tantal, Niob and tungsten carbide, cemented carbide can be produced.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento