What Is The Si3N4 Ceramic Powder Granulation?

Silicon nitride ceramic (Si3N4) has quantifiable mechanical properties including strength, hardness, fracture toughness and self‐lubricating behaviour. It is under investigation in high performance ceramic research.

Si3N4 ceramic powders are the essential raw materials for the production of Si3N4 ceramics. The granulation process is a key procedure that influences the ceramic’s density and mechanical attributes. Consequently, it is necessary to investigate the granulation treatment of Si3N4 powders and select the appropriate method according to actual production conditions.

![]()

Granulation Methods for Silicon Nitride Ceramic Powders

During industrial production, Si3N4 ceramic powders are granulated by dry roll granulation, cold isostatic pressing and spray granulation. Compared with other oxide ceramic powders, Si3N4 ceramics are temperature sensitive during sintering. As a result, powder particle size and surface morphology must be controlled precisely.

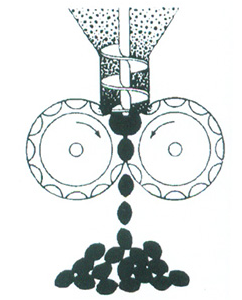

1. Dry Roll Granulation

Dry roll granulation is a dry extrusion process. In this process, Si3N4 ceramic powder with a water content below 10% is pressed into a plate. The compacted block is subsequently crushed, granulated and sieved to yield granules that meet application requirements. The method relies on external pressure to compact the powder through the gap between two rotating rolls. During rolling, the material density increases by a factor between 1.5 and 3 to satisfy specified strength requirements. Dry roll granulation offers high granulation efficiency and low production cost. It requires a lower binder content than spray granulation.

2. Cold Isostatic Pressing Granulation

Cold isostatic pressing granulation involves placing Si3N4 ceramic powder into a specialised mould. The mould is then processed in a cold isostatic press, where equal pressure is applied in every direction. The resulting compact is later broken and sieved. This method exploits the incompressibility of the liquid medium and equal pressure transmission to ensure that the powder is uniformly pressed from all directions.

3. Spray Granulation

Spray granulation is a process in which a mixed slurry is sprayed into heated air and rapidly dried to form spherical powder particles. Centrifugal or pressure spray granulation equipment is used to mix the Si3N4 slurry with the granulate simultaneously. This procedure ensures that the Si3N4 powder is uniformly distributed. Particle sphericity and flowability improve, and the particle size distribution is controlled. Process parameters such as temperature, pressure, feed rate, mixing time and binder type significantly influence the final powder size and dispersion.

Spray granulation avoids agglomeration and sedimentation of slurry components. It preserves the initial uniformity of the slurry and produces a controlled particle size distribution with good flowability. The technology enables continuous automated production, improves production efficiency and reduces dust levels. Its application can enhance the density and uniformity of the compact and improve sintering performance. Spray granulation is widely used in the chemical, metallurgical, ceramic, cement, food and medical industries.

Furthermore, the choice of binder is an important factor in the spray granulation process. Currently, phenolic resin and polyvinyl alcohol are generally used as binders. Ethylene glycol is readily soluble in ethanol and can be fully mixed using a roll ball mill. After treatment, the powder particles are uniform, exhibit good sphericity and display high sintering reactivity.

The technology of Si3N4 ceramic powder granulation demonstrates that powder post‐treatment is a systematic process involving multiple units and disciplines. Given that this represents a new industrial sector, powder granulation is receiving increased attention. Technological advancements and improved granulation equipment have led to its widespread adoption.

- END -

About the Author

Cathie Montanez is the project scientist at Stanford Advanced Materials (SAM). She previously served as a research professor in the School of Materials Science and Engineering at the University and is now responsible for performance testing and technical consultancy of SAM products such as refractory metals, ceramics, laboratory crucibles and grinding mills, etc.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento