What Is The Use Of Tungsten-Copper Alloy?

Tungsten-Copper Alloy is an alloy composed of Tungsten and Copper. Standard tungsten-copper alloys contain 10 to 50 % copper. The alloy is produced via powder metallurgy and exhibits excellent electrical conductivity, thermal conductivity, good high‐temperature strength and moderate ductility. At extremely high temperatures, above 3000 °C, the copper liquifies and evaporates. This evaporation absorbs heat and reduces the material’s surface temperature. Please read on; this article details key applications of tungsten-copper alloys.

-

High-Temperature Resistant Materials for Defence

Tungsten-copper alloys are used in the aerospace sector for manufacturing rockets, nozzle components for rocket engines, gas vanes, air vanes and nose cones. The critical specifications are high‐temperature resistance (3000 K to 5000 K) and resistance to high‐temperature airflow. The evaporation of copper at high temperatures (copper melting point 1083 ℃) produces a cooling effect. This cooling effect lowers the surface temperature of the tungsten-copper alloy and permits use under extreme conditions.

-

Electrical Alloy for High Voltage Switches

Tungsten-copper alloy is widely used in high voltage switches, for example, in a 128 kV SF6 power switch (WCu/CuCr), high voltage vacuum switches (12 kV, 40.5 kV, 1 000 A) and lightning arrestors. The high voltage vacuum switch is compact and easy to maintain. It operates in humid, flammable, explosive and corrosive environments. The major performance criteria are resistance to arc erosion, resistance to melt welding, low interrupt current, minimal air content and low thermionic emission. Porosity and microstructural integrity are also required. Consequently, specific procedures such as vacuum degassing and vacuum infiltration are employed.

-

Electrodes for EDM Applications

Initially, copper or graphite electrodes were used for electrodischarge machining. They were cost-effective but not sufficiently wear-resistant. They were replaced by tungsten-copper electrodes. Tungsten-copper electrodes provide high temperature resistance and retain strength at elevated temperatures. They resist arc erosion. They offer efficient electrical conductivity, good thermal conductivity and rapid heat dissipation. They are used for spark erosion electrodes, resistance welding electrodes and high voltage discharge tube electrodes.

-

Microelectronic Materials

Tungsten-copper materials for electronic enclosures and heat sinks combine tungsten’s low thermal expansion with copper’s high thermal conductivity. The coefficient of thermal expansion and thermal conductivity can be adjusted by modifying the alloy composition. Tungsten-copper exhibits high heat resistance and efficient thermal conductivity. Its thermal expansion coefficient is compatible with that of silicon wafers, gallium arsenide and ceramic materials. It is therefore used in semiconductor applications. It is suitable for packaging high performance devices. It is also applied in heat sink components, thermal conduction elements, ceramics and gallium arsenide bases.

Conclusion

Thank you for reading this article. We trust it has clarified the applications of tungsten-copper alloys. If further information is required, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials has over two decades of experience in the manufacture and distribution of tungsten-copper alloys. They supply quality materials for both research and production needs. Consequently, SAM is likely to be your preferred supplier and business partner for tungsten-copper alloys.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

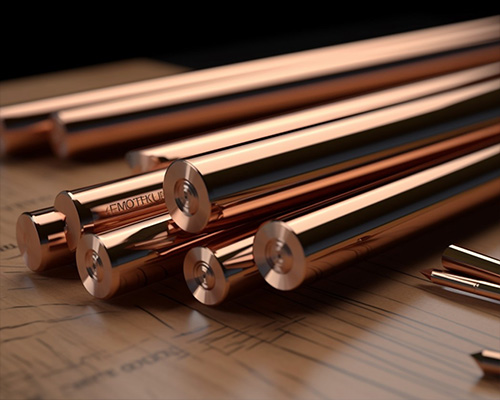

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento