Which Inorganic Powder Filler Will Win In The 5G Copper Clad Markets?

5G, fully known as the mobile communications standard of the fifth generation, marks the start of the 5G era. This also upgrades the electronic information industry. The market for copper-clad laminates is being upgraded gradually.

To meet the demand for high-frequency and high-speed switching in the 5G era, the performance of copper-clad 5G plates must be improved. Research confirms that adding inorganic fillers improves the properties of copper-clad laminates. Consequently, inorganic fillers are gaining significance. Inorganic fillers have become the fourth most important raw material for copper-clad laminates and hold a defined position in the 5G copper-clad plates market.

Why are inorganic fillers important for 5G copper-clad plates?

* Reduction of production costs for 5G copper-clad plates

Fillers exhibit a volume effect. The substitution of a portion of costly resin with inexpensive inorganic fillers reduces production costs. This change improves market competitiveness.

* Improvement of the performance of copper-clad 5G plates

Electronic components on copper-clad laminates are highly integrated. Their heat output per area increases accordingly. The thermal conductivity of the plates is enhanced by adding inorganic fillers with high thermal conductivity.

* Improvement of the production process of 5G copper-clad plates

Inorganic fillers control the viscosity of the adhesive and reduce the flowability of the semi-cured plate. This adjustment improves the production process. The fillers also reduce the amount of adhesive in the subsequent densification process, enhance the uniformity of plate thickness, and improve the flatness of the appearance. Consequently, 5G copper-clad plates with extremely low roughness and uniform thickness are produced.

Types of inorganic fillers for 5G copper-clad plates

1. Silicon dioxide powder

The insulating layer of 5G copper-clad plates is filled with silicon dioxide powder. All forms of this powder reduce the reactivity and fluidity of the resin system. They also improve plate stiffness, moisture resistance and toughness. Spherical silicon dioxide powder reduces the coefficient of thermal expansion, enhances electrical insulation and improves heat resistance. It also facilitates the drilling process and sheet forming.

![]()

2. Aluminium hydroxide

Aluminium hydroxide is used as a flame retardant. It reduces surface decomposition and the formation of carbonaceous particles. Consequently, the non-flammability of the material is enhanced. It also reduces the coefficient of thermal expansion and the water absorption of the plates.

3. Spherical alumina

Spherical alumina offers high filling efficiency, high thermal conductivity and low wear. It improves thermal conductivity, accelerates heat dissipation and reduces both the dielectric constant and the coefficient of thermal expansion.

4. Titanium white powder

Titanium white powder alters the colour of the insulating layer and increases its whiteness. It is used in the production of white copper-clad LED plates on chip substrates.

Aluminium nitride exhibits good thermal conductivity and a low coefficient of thermal expansion. It provides effective electrical insulation. It also improves the thermal conductivity and various electrical properties of the plate.

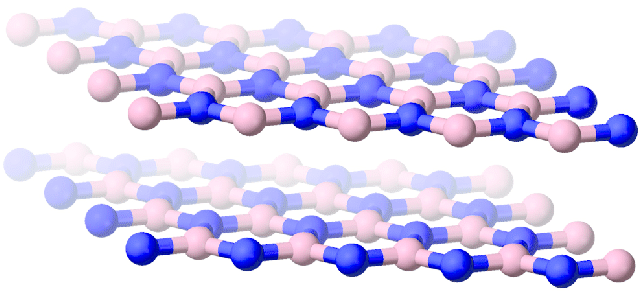

6. Hexagonal boron nitride (H-BN)

Hexagonal boron nitride has a low friction coefficient and a low expansion coefficient. It offers stable performance at high temperatures, good resistance to thermal cycles, strength and high thermal conductivity. It also demonstrates high specific resistance and corrosion resistance. These qualities enhance the performance of the plate.

Silicon carbide shows high thermal conductivity and a low coefficient of thermal expansion. It improves the thermal conductivity of 5G copper-clad plates and reduces their thermal expansion.

8. Other inorganic powder fillers

Other inorganic powder fillers such as talc, mica powder and bromite enable efficient filling. Their use reduces material costs.

Growing trend

The development of the 5G communications market necessitates continuous improvements in copper-clad plates. A 5G copper-clad plate must offer low loss, a low dielectric constant and an extremely low surface roughness of the copper foil. It must also ensure adequate peel strength and uniform thickness. In addition, the plate must exhibit minimal impedance variation, higher heat resistance and an efficient processing technology for PCBs. Consequently, only inorganic fillers that enhance the function, reliability and stability of the copper-clad plate will maintain their market position.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento