Stanford Advanced Materials (SAM) provides services for custom single crystals. The company specialises in manufacturing alloy single crystals, exotic materials and custom single crystal geometries. This expertise enables the production of single crystals that meet strict tolerance levels for applications including crystal substrates, laser crystals and scintillation crystals.

Our commitment extends to final processing. We supply polished and oriented single crystals and polished curved single crystal surfaces. These single crystals are fabricated to a specified surface roughness for applications including windows, NLO crystals, prisms and lenses.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

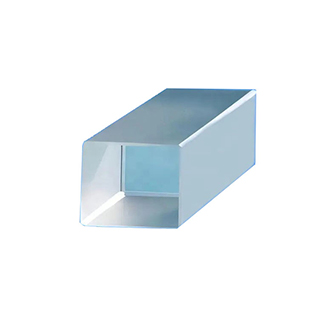

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators