Case Study: Enabling Advancements In Nuclear Energy With Beryllium Foil

Introduction

Beryllium Foil plays an important role in the nuclear energy sector and contributes to several aspects of nuclear engineering and research. Its specific properties and applications improve reactor performance, fuel efficiency and safety measures in nuclear energy. This article discusses its specific applications in nuclear energy.

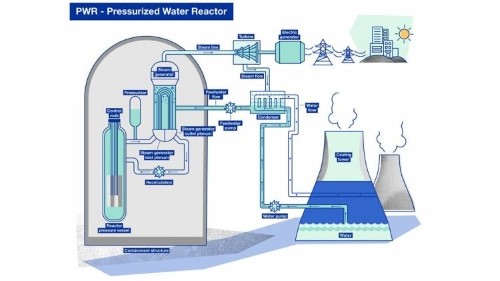

[1]

[1]

Figure 1. Nuclear Reactors

Understanding Beryllium Foil

Beryllium foil is a thin sheet of beryllium. It is a lightweight, high-strength metal with low density that exhibits good thermal conductivity, electrical conductivity and permeability to X-rays and ionising radiation. These properties support various functions in multiple industrial and research fields.

Figure 2. Beryllium Foil

Applications of Beryllium Foils in Nuclear Energy

Beryllium foil has several applications, particularly in the nuclear energy field. Below are a few examples.

Moderation and Neutron Reflection: Beryllium has a low neutron absorption cross-section and high scattering capacity. It is used as a neutron moderator and reflector in nuclear reactors. This slows fast neutrons. Consequently, the slower neutrons interact better with fissionable materials such as Uranium‑235 and Plutonium‑239.

Trident Nuclear Weapons: It is used as a component in the construction of the Trident nuclear warhead. Its mechanical properties, such as high stiffness and low density, permit its use in the warhead’s detonator system.

Fusion Reactors: This foil is employed as a plasma‑facing material in fusion reactors. It withstands high temperatures, has a low atomic number and resists plasma bombardment. Given that these properties minimise plasma contamination, it is used for lining the walls of fusion devices such as tokamaks. Its use results in effective heat and radiation management.

Radiation Windows and Shielding: The properties of beryllium foil extend to its use in radiation windows and shielding. Because it has low absorption of X‑rays and gamma rays, it is suitable for windows in radiation detectors that permit these high‑energy photons for analysis. Beryllium shielding is used to protect sensitive equipment from radiation and to increase safety in nuclear research.

It is important to note that beryllium presents potential health risks. Inhalation of dust or fumes can affect health. Proper handling, disposal and adherence to safety protocols are required to reduce risks for workers and the environment.

Conclusion

In summary, diverse applications of beryllium foil in nuclear energy illustrate its contribution to improving reactor performance, fuel utilisation and safety protocols. Whether it is used for neutron moderation, fusion research or nuclear weapons technology, the properties of beryllium help shape the field of nuclear energy and research, thereby emphasising the importance of safety protocols.

Beryllium foil (Be‑foil) is offered by Stanford Advanced Materials (SAM. Customised forms and component ratios of beryllium products are also available. Please submit an enquiry if you are interested.

Reference:

[1] Galindo, A. (2022). What is Nuclear Energy? The Science of Nuclear Energy [Photo]. https://www.iaea.org/newscenter/news/what-is-nuclear-energy-the-science-of-nuclear-power

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento