High-entropy Alloys For Thermoelectric Applications

Introduction

High‐entropy alloys (HEAs) have been studied for thermoelectric high‐temperature applications owing to their distinct properties. The following text sets out specific advantages of utilising HEAs in thermoelectric applications. Our aim is to improve the understanding of the characteristics and applications of high‐entropy alloys.

What is a High‐Entropy Alloy?

A high‐entropy alloy is an alloy that contains at least 5 elements in equiatomic or near‐equiatomic proportions. In contrast to conventional alloys, which have a single primary element, high‐entropy alloys consist of multiple principal elements. This composition results in a random atomic arrangement, a high configurational entropy and, importantly, notable properties and applications.

HEAs are distinguished by properties that conventional alloys do not exhibit. These properties include high strength, considerable ductility, high electrical conductivity and favourable thermal stability. They also possess high wear resistance, corrosion resistance and reliable performance at high temperatures, thereby making them suitable for use in demanding environments.

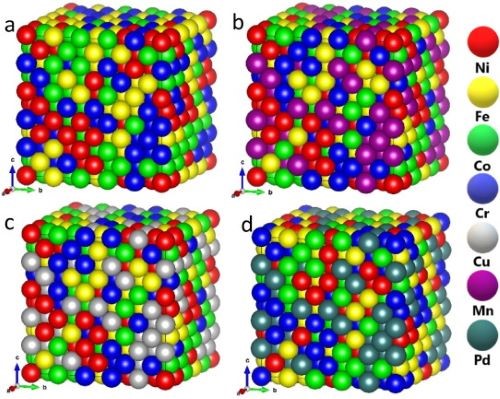

[1]

[1]

Figure 1. Examples of high‐entropy alloys

Because of these structural and functional characteristics, HEAs have a range of applications in sectors such as aerospace, automotive and biomedical. This article addresses high‐entropy alloys that are employed in thermoelectric applications.

What are Thermoelectric Materials?

The use of thermoelectric (TE) technology has grown in response to a steadily increasing energy demand. On one hand, a substantial quantity of renewable energy is harnessed to meet rising requirements. On the other hand, TE technology can convert waste heat into electrical energy. TE materials are also valued for their compact operational size and may be used in solid‐state cooling as well as portable electronics.

For the direct conversion of waste heat into electrical energy, TE technology employs a range of advanced materials. Common thermoelectric materials include Zintl, Heusler, SiGe, MgSi, clathrates and CoSb3–Ba. Pb(Te, Se, S)–SeTe, SiGe and skutterudites have also been used. [2] Various high‐entropy alloys have been developed for thermoelectric applications that demand performance at high temperatures.

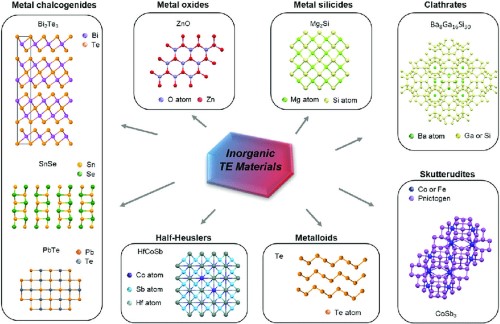

[3]

[3]

Figure 2. Examples of TE materials

Why are High‐Entropy Alloys Suitable for Thermoelectric Applications?

High‐entropy alloys are well suited for thermoelectric applications due to the following properties.

- High Thermal Stability

Firstly, the high configurational entropy results in a random distribution of atoms and, consequently, high thermal stability. This atomic arrangement reduces the occurrence of phase transitions even at elevated temperatures, thereby making HEAs appropriate for thermoelectric applications.

- High Thermal Conductivity

Secondly, the metallic nature of these alloys contributes to a high thermal conductivity. This facilitates a high electron mobility and reduces resistance to heat flow, thereby improving heat transfer efficiency.

- High Electrical Conductivity

In addition to their thermal properties, HEAs exhibit high electrical conductivity, which permits efficient conversion of heat into electrical energy. As a result, HEAs provide a viable option for thermoelectric power generation.

-- Low Thermal Expansion Coefficient

Due to their random atomic arrangement, HEAs exhibit a low thermal expansion coefficient. This reduces the likelihood of thermal stresses or deformations.

- Enhanced Mechanical Properties

The disordered structure also leads to enhanced mechanical properties, such as high strength and ductility. These properties enable HEAs to withstand severe operating conditions in high‐temperature thermoelectric applications.

Conclusion

In conclusion, HEAs offer several advantages for thermoelectric applications, including high thermal stability, high thermal and electrical conductivity, a low coefficient of thermal expansion and enhanced mechanical properties. Consequently, these properties allow the development of thermoelectric devices with improved energy conversion efficiency and a longer operational lifetime.

Stanford Advanced Materials (SAM) is a reliable supplier of high‐entropy alloys. Many high‐quality HEAs are available for thermoelectric applications, 3D printing and other uses. HEAs are available in multiple forms and specifications. Please submit an enquiry if you are interested.

References:

[1] Saro San, Yang Tong, Hongbin Bei, Boopathy Kombaiah, Yanwen Zhang, Wai‐Yim Ching, First‐principles calculation of lattice distortions in four single‐phase high‐entropy alloys with experimental validation, Materials & Design, Volume 209, 2021, 110071, ISSN 0264–1275, https://doi.org/10.1016/j.matdes.2021.110071.

[2] Shafeie, Samrand & Guo, Sheng. (2020). Advantages of selecting and using high‐entropy alloys for thermoelectric high‐temperature applications. 10.1201/9780367374426-16.

[3] Zeng, Minxiang & Zavanelli, Duncan & Chen, Jiahao & Saeidi-Javash, Mortaza & Du, Yipu & LeBlanc, Saniya & Snyder, G. & Zhang, Yanliang. (2021). Thermoelectric printing inks for energy and heat devices. Chemical Society Reviews, 51. 10.1039/D1CS00490E.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento