Several Important Aspects Of High-entropy Alloy That You Must Know

Introduction

High-entropy alloys (HEAs) are a class of advanced materials that provide an alternative to conventional alloys. The text below summarises essential information about HEAs. It aims to facilitate a factual understanding of these materials for future applications.

[1]

[1]

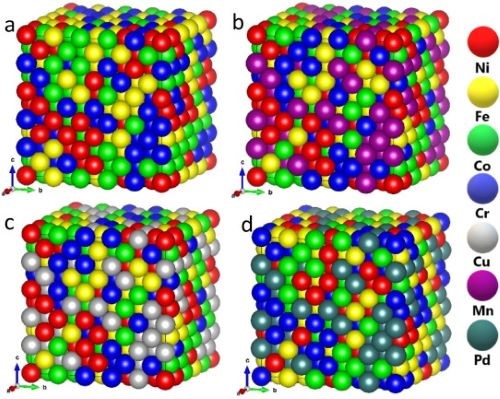

Figure 1. Examples of high-entropy alloys

What is a high-entropy alloy?

-Definition

A high-entropy alloy (HEA) is an advanced material containing five or more metallic elements and features a random crystalline structure with high configurational entropy. HEAs differ from conventional alloys as they do not have a primary component. Instead, they consist of several principal elements in equal or nearly equal proportions. The high configurational entropy yields distinct properties and applications.

-Properties

HEAs exhibit a group of specific properties that are not observed in conventional alloys. These properties include high strength, ductility and thermal stability. They also show excellent wear resistance, corrosion resistance and performance at high temperatures. For example, VNbMoTaW demonstrates a yield strength in excess of 600 MPa (87 ksi) at 1 400 °C. CoCrFeMnNi has been observed to exhibit notable mechanical behaviour at low temperatures along with high fracture toughness. Al0,5CoCrCuFeNi records an extended fatigue life compared with traditional steel and titanium alloys.

-Manufacturing

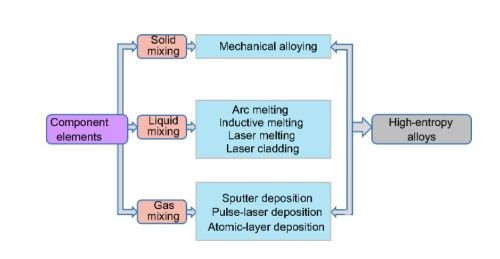

Manufacturing HEAs requires specialised techniques due to their complex composition and microstructure. Methods such as powder metallurgy, electrodeposition and mechanical alloying are employed. Most HEAs are produced using arc melting and induction melting; sputtering, molecular beam epitaxy (MBE) or mechanical melting may also be used. These techniques are applied to achieve HEAs with a tailored microstructure and defined properties for specific applications.

Figure 2. HEA production methods

-Application

HEAs have been investigated for employment in high-temperature thermoelectric systems, wear-resistant coatings and structural materials. They have also been studied for use in the aerospace, automotive and biomedical fields. Their unique combination of properties makes them suitable for operation in harsh conditions given that conventional alloys may fail under similar circumstances. In the automotive industry, HEAs are used to produce engine components, drive systems and other structural parts. In addition, the alloys provide radiation and corrosion resistance suitable for certain nuclear applications.

Four Fundamental Principles of High-entropy Alloys

The following section outlines the basic principles underlying high-entropy alloys.

1. Entropic Stabilisation of Solid Solutions

The first effect is entropic stabilisation. High configurational entropy stabilises the solid solution phase, thereby yielding a lower Gibbs energy than intermetallic phases. [2]

2. Significant Lattice Distortion

Lattice distortion occurs due to the differences in atomic sizes among the constituent elements. This factor influences the physical and mechanical behaviour of HEAs.

3. Slow Diffusion Kinetics

HEAs exhibit slow diffusion kinetics. Atoms in these solid solutions move at a reduced rate given the high concentration of elements, thereby affecting material processing.

4. The Cocktail Effect

The complexity of HEA compositions results from the interactions among multiple elements. These interactions produce physical properties that cannot be predicted solely from the individual characteristics of each element. This phenomenon is referred to as the cocktail effect. The element interactions generate measurable properties which require detailed investigation.

Conclusion

In summary, high-entropy alloys combine distinct properties, specific production methods and the capacity for varied applications. They are defined by (1) entropic stabilisation, (2) significant lattice distortion, (3) slow diffusion kinetics and (4) the cocktail effect. Further investigation of HEAs is expected to elucidate their potential for developing advanced materials for diverse applications. Stanford Advanced Materials (SAM) supplies high-entropy alloys. Please contact us if further details are required.

Reference:

[1] Saro San, Yang Tong, Hongbin Bei, Boopathy Kombaiah, Yanwen Zhang, Wai-Yim Ching, First-principles calculation of lattice distortions in four single phase high entropy alloys with experimental validation, Materials & Design, Volume 209, 2021, 110071, ISSN 0264-1275, https://doi.org/10.1016/j.matdes.2021.110071.

[2] Pickering, E., & Jones, N. (2016). High-Entropy Alloys: A critical assessment of their founding principles and future prospects. International Materials Review. https://doi.org/10.1080/09506608.2016.1180020

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento