Something You Should Know About Lithium-Ion Battery

Introduction

Lithium-ion batteries, frequently abbreviated as LIBs, are rechargeable energy storage devices that have become the standard for powering a variety of modern technologies. From smartphones and laptops to electric vehicles and renewable energy storage systems, LIBs have changed the methods by which electrical energy is utilised and stored. This article examines the role of LIBs in these sectors and provides detailed information on their operating principles, raw materials, advantages and applications.

[1]

[1]

Figure 1. Lithium-ion battery

Operating Principles of Lithium-ion Batteries

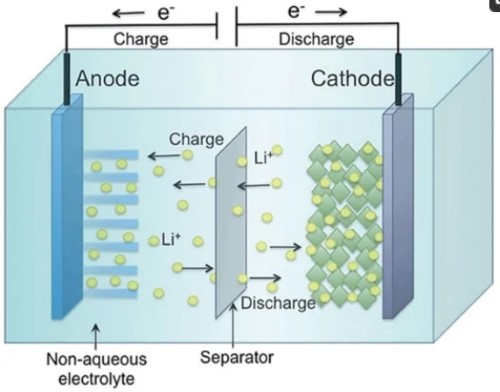

Lithium-ion batteries operate on an electrochemical process. They function by moving lithium ions (Li+) between two primary components: the anode and the cathode. During the charging phase, lithium ions are removed from the cathode and stored in the anode, thereby creating a potential difference. During the discharging phase, as the battery supplies power, these ions pass through an electrolyte solution back to the cathode.

[2]

[2]

Figure 2. Structure of a lithium-ion battery

Materials in Lithium-ion Batteries

In the electrochemical process, different LIB materials are selected and developed to maximise battery performance, energy density and overall efficiency. The following are the main components of lithium-ion battery materials:

-Anode Materials

Anodes in LIBs typically consist of materials that can absorb and release lithium ions during charging and discharging cycles. Common anode materials include graphite and silicon.

lGraphite is the most common anode material in commercial lithium-ion batteries due to its stability and electrochemical performance.

lSilicon offers a higher theoretical capacity for storing lithium compared to graphite. The expansion and contraction of silicon during lithiation and delithiation cycles poses a technical challenge.

-Cathode Materials:

Cathodes determine battery voltage and capacity. Different cathode materials present varying voltage plateaus and energy densities.

lLithium cobalt oxide (LiCoO2) was frequently used in early LIBs, particularly in consumer electronics. It provides an acceptable energy density, although its use in high-capacity and high-power applications is limited owing to safety concerns and cost.

lLithium iron phosphate (LiFePO4) is known for its safety and long cycle life. It is used in electric vehicles and renewable energy storage systems where safety and durability are necessary.

lLithium nickel cobalt manganese oxide (NCM) and lithium nickel cobalt aluminium oxide (NCA) cathodes are frequently employed in batteries for electric vehicles. They balance energy density with power density.

lLithium manganese oxide (LMO) is valued for its thermal stability and safety, and is suited for applications that require effective temperature control.

-Electrolyte:

The electrolyte is the conducting medium that enables the movement of lithium ions between the anode and cathode during charging and discharging. Common electrolytes include lithium salts dissolved in organic solvents, although solid-state electrolytes are also under development to improve safety and energy density.

-Separators:

Separators are porous membranes that physically separate the anode and cathode while allowing the transfer of lithium ions. They are usually composed of polyethylene (PE) or polypropylene (PP) and help to prevent short circuits and enhance safety.

Advantages of Lithium-ion Batteries

Lithium-ion batteries are used in various applications because of the following features:

lEfficiency: LIBs offer a high energy density, are rechargeable and exhibit a low self-discharge rate.

lDurability: LIBs operate across a wide temperature range, from sub-zero conditions to high temperatures. They undergo many charge and discharge cycles before a significant reduction in capacity is observed.

lSustainability: LIBs produce fewer emissions and possess a lower environmental impact compared to some alternative energy storage solutions.

lSafety: Modern LIBs incorporate safety features such as thermal protection, overcharge protection and integrated battery management systems (BMS) to monitor and control battery performance and safety.

Applications of Lithium-ion Batteries

LIBs have been implemented in various sectors as a result of their characteristics:

lConsumer Electronics: LIBs supply smartphones, tablets, laptops, cameras and other portable devices with the power required for modern connectivity.

lElectric Vehicles (EVs): LIBs serve as the primary energy storage system in electric vehicles. They store large quantities of energy and deliver it efficiently, thereby supporting the growth of the electric vehicle market.

lRenewable Energy Storage: LIBs are essential for storing electricity generated from renewable sources such as solar panels and wind turbines. The stored energy can be deployed during periods of low generation or at peak demand.

lAerospace: LIBs are used in aerospace applications, for instance in satellites, spacecraft and unmanned aerial vehicles (UAVs), where high energy density and reliable performance are required.

lMedical Devices: LIBs are employed in medical devices to ensure that critical equipment, such as implantable cardioverter-defibrillators (ICDs) and portable medical monitors, remain operational when required.

Conclusion

In summary, lithium-ion batteries provide a viable solution for clean, efficient and sustainable energy storage. They change the way in which devices, vehicles and renewable energy systems receive power, supported by their high energy density, extended service life and versatility.

Stanford Advanced Materials (SAM) supplies a range of lithium-ion battery materials, including lithium nickel cobalt manganese oxide (NCM), lithium nickel cobalt aluminium oxide (NCA), lithium cobalt oxide (LCO) and lithium iron phosphate (LFP). Please contact us if interested.

Reference:

[1] Chandler, D. L. (23/03/2023). Study indicates cost reduction in lithium-ion batteries. MIT News. Retrieved on 12/09/2023, from https://news.mit.edu/2021/lithium-ion-battery-costs-0323

[2] Ghiji, M.; Novozhilov, V.; Moinuddin, K.; Joseph, P.; Burch, I.; Suendermann, B.; Gamble, G. A Review of Lithium-Ion Battery Fire Suppression. Energies 2020, 13, 5 117. https://doi.org/10.3390/en13195117

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento