Case Study: Revolutionizing Automotive Innovation With Tantalum-Niobium Foil

Introduction

Tantal-Niob Foils (Ta-Nb Foils) derived from a Tantalum–Niobium alloy are gaining importance in the automotive industry, where advanced materials are critical for improving performance and reducing fuel consumption. These foils are comprised of Tantalum and Niobium and exhibit defined properties such as a high melting point, strong corrosion resistance, low density and high thermal and electrical conductivity. This case study examines the use of Tantal-Niob Foils in automotive components and their measured contribution to vehicle technology.

[1]

[1]

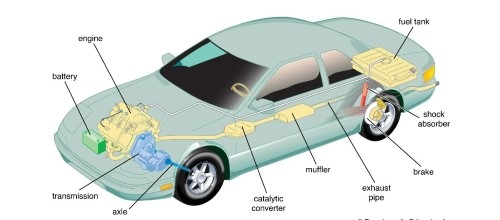

Figure 1. Automotive Components

Performance of Tantal-Niob Foils

Tantal-Niob Foils are more than a mere combination of metals. The integration of Tantalum and Niobium in thin sheets produces a composite material that retains the chemical properties of both transition metals. These include a high melting point, proven corrosion resistance, low mass and high thermal and electrical conductivity. Consequently, these measured properties support their applications in the automotive sector.

Figure 2. Tantal-Niob Foil

Applications in the Automotive Sector

1. Capacitors for improved electronics: Tantal-Niob Foils are used extensively in the manufacture of high-performance capacitors. These capacitors serve as essential electronic components in automotive systems, such as engine control units (ECUs), power management modules and advanced driver assistance systems (ADAS). They deliver a high capacitance, stable performance and a low equivalent series resistance (ESR), which is required for critical automotive applications.

2. Promoting miniaturisation: Ta-Nb Foils are utilised in the production of microelectronic components and integrated circuits for vehicle electronics. This contributes to the miniaturisation and improved functionality of control units, sensors and communication modules in vehicles.

3. Withstanding high temperatures: The foils demonstrate resistance to elevated temperatures. They are deployed in automotive exhaust systems and engine components where they function as thermal barriers and protective coatings in parts that are exposed to heat. Consequently, their use enhances durability and service life.

4. Facilitating lightweight construction: They are applied as lightweight materials in specific automotive components. Their high strength-to-weight ratio enables the design of parts that are lighter while maintaining structural integrity, thereby reducing overall vehicle mass and improving fuel efficiency.

5. Resistant to corrosion: The notable corrosion resistance of Tantal-Niob Foils makes them a valued material for automotive applications exposed to harsh conditions, such as road salts and corrosive fluids. They are incorporated in critical components to improve durability and ensure performance under challenging conditions.

6. Advanced batteries: These foils are also employed in lithium-ion battery technologies, which are increasingly used in electric and hybrid vehicles. Ta-Nb Foils contribute to the efficiency, performance and safety of batteries, thereby supporting the progress of battery technology.

Conclusion

In summary, the applications of Tantal-Niob Foils in the automotive sector illustrate their role in shaping future automotive technologies. Their contributions to automotive electronics, thermal management, lightweight construction and corrosion mitigation play a significant part in enhancing vehicle performance, sustainability and safety.

Stanford Advanced Materials (SAM) is a supplier and manufacturer of Tantal-Niob Foils and other products derived from Tantal-Niob. For further information, please visit our homepage.

Reference:

[1] Encyclopædia Britannica (2023). Automobile [Photograph]. https://www.britannica.com/technology/automobile#/media/1/44957/120667

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

.jpg)

Chin Trento

Chin Trento