Solid-State Batteries: The Future Of Electric Vehicle Energy Storage

Introduction

In the continuously developing field of electromobility, the pursuit of safer, more efficient and environmentally responsible energy storage solutions has led to the use of solid‐state batteries. This article examines how these batteries provide an improved outlook for energy storage in electric vehicles (EV). We aim to clarify both the advantages and the limitations of solid‐state batteries.

[1]

[1]

Figure 1. Solid‐State Batteries

Understanding Solid‐State Batteries

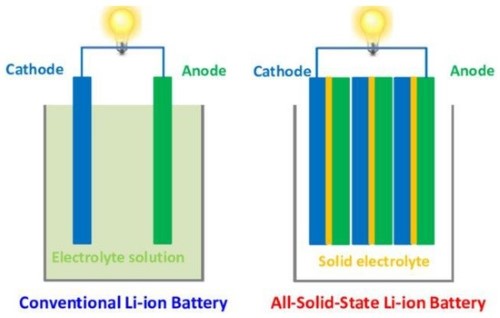

Solid‐state batteries offer an alternative method for energy storage. They replace the conventional liquid or gel electrolyte, found in Lithium‐Ion Batteries (Li‐Ion), with a solid electrolyte. Most internal components – including the electrolyte, electrodes and separators – are made from solid materials. Here is a detailed explanation:

[2]

[2]

Figure 2. Solid‐State Batteries vs. Lithium‐Ion Batteries (Li‐Ion)

Solid Electrolyte: The principal component in a solid‐state battery is the solid electrolyte. It is usually composed of materials such as ceramics, polymers or glass that offer high ionic conductivity. The electrolyte supports the transfer of lithium ions (Li+) between the cathode and anode during charge and discharge cycles.

Cathode and Anode: As with conventional Lithium‐Ion batteries, the cathode contains lithium‐based compounds, for example, Lithium Cobalt Oxide (LiCoO2) or Lithium Iron Phosphate (LiFePO4). The anode is typically manufactured from materials such as lithium metal, Lithium Titanate (Li4Ti5O12) or other lithium‐intercalating substances.

Advantages of Solid‐State Batteries

Solid‐state batteries may offer several benefits compared with Lithium‐Ion batteries (Li‐Ion):

1. Safety: They provide a safer design by replacing the liquid electrolyte with a solid one, thereby eliminating the risk of thermal runaway.

2. High Energy Density: They have the potential to store more energy within a smaller and lighter package, thereby increasing the range of electric vehicles without substantial increases in size or weight.

3. Fast Charging: They support high‐speed charging that can reduce charging time from hours to minutes. Consequently, charging efficiency is improved.

4. Extended Lifespan: They are capable of withstanding a greater number of charge and discharge cycles before replacement is required, thereby potentially reducing maintenance costs and extending overall vehicle lifespan.

5. Broad Temperature Range: They function efficiently in a wider range of temperatures than Lithium‐Ion batteries, thus guaranteeing consistent performance in both hot and cold conditions.

6. Reduced Environmental Impact: They often use materials that are more sustainable, such as solid electrolytes and electrodes, thereby lessening the environmental impact associated with production and disposal.

7. Compatibility with Solid‐State Electronics: Their solid nature makes it feasible to integrate them with solid‐state electronics, thereby supporting the development of more efficient battery systems in EVs.

Although solid‐state batteries offer several benefits, they remain in the research and development phase. They face challenges including scalable production and cost reduction. Several automotive manufacturers and battery producers are investing in solid‐state battery technology, and commercialisation efforts are underway.

Conclusion

In summary, solid‐state batteries provide enhanced safety, increased energy density, faster charging capabilities, a longer lifespan and stable performance over a wide temperature range. These attributes contribute to a safer and more efficient future for energy storage in electric vehicles (EVs). Consequently, their use may reduce the environmental impact of EVs through the adoption of more sustainable materials.

Stanford Advanced Materials (SAM), a prominent provider in the field of advanced EV batteries, is at the forefront of these developments. With its commitment to efficiency, SAM offers competitive pricing and tailored solutions for specific requirements. Should you be interested in our offerings or have any queries, please do not hesitate to contact us.

References:

[1] Winton, N. (28/11/2021). Solid‐State Batteries Promise Electric Car Popularity Boost, But Technical Mountains Await. Forbes. Retrieved on 20/09/2023, from https://www.forbes.com/sites/neilwinton/2021/11/28/solid-state-batteries-promise-electric-car-popularity-boost-but-technical-mountains-await/?sh=1ad7615632fa.

[2] Majid, M.F.; Mohd Zaid, H.F.; Kait, C.F.; Ahmad, A.; Jumbri, K. Ionic Liquid@Metal-Organic Framework as a Solid Electrolyte in a Lithium-Ion Battery: Current Performance and Perspective at Molecular Level. Nanomaterials 2022, 12, 1 076. https://doi.org/10.3390/nano12071076

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento