Top 5 Methods For Effective Metal Cutting

Introduction

The effective cutting of metal requires the correct method to ensure precision, speed and quality. Each method offers specific advantages and is suitable for certain applications. This article describes the five main procedures for metal machining with details of their merits and common uses.

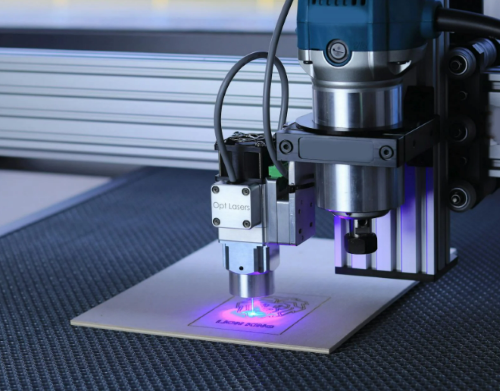

1. Laser Cutting

Laser cutting is a high-precision process in which a focussed laser beam is employed to melt, burn or vapourise metal. The process achieves tight tolerances and detailed features and is therefore appropriate for applications requiring high precision.

[1]

[1]

-Advantages:

Laser cutting provides accuracy and permits the production of complex shapes and intricate details. The method processes thin materials rapidly, thereby increasing productivity. It produces high-quality edge finishes that often eliminate the need for post-processing. In addition, laser cutting is versatile and may process various metals including steel, aluminium and titanium.

-Applications:

Laser cutting is used in industrial manufacturing for the production of precision components. It is employed in the automotive sector for cutting metal parts and in the aerospace industry for producing detailed components. Metal fabrication businesses also adopt laser cutting for customised designs and products.

Read more: Types of high-temperature refractory metal materials for laser forming

2. Water Jet Cutting

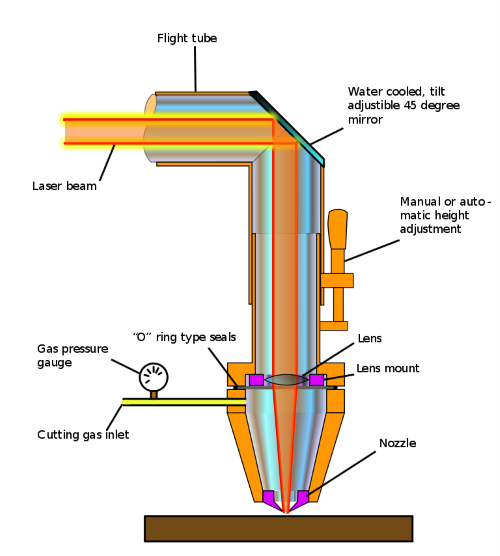

In water jet cutting, a high-pressure water jet – occasionally combined with an abrasive – is used to cut metal. The method is valued because no heat affected zone (HAZ) is produced, thereby preserving the material’s structural integrity.

[2]

[2]

-Advantages:

The primary advantage of water jet cutting is the absence of a heat affected zone, which maintains the material’s properties. The method is versatile and can process various materials including metals, composites and ceramics. It is effective when cutting thick materials and is environmentally friendly because it does not produce hazardous fumes or residues.

-Applications:

Water jet cutting is applied in the aerospace industry for precision component cutting. It is also used in the automotive sector and in the production of metal art and sculptures. Specialist fabrication businesses employ water jet cutting due to its versatility and precision.

3. Plasma Cutting

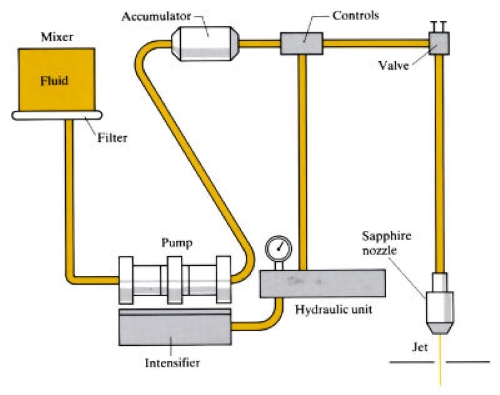

Plasma cutting utilises a high-velocity, high-temperature plasma jet to cut electrically conductive materials. The method is recognised for its speed and efficiency when processing thin to medium-thickness metals.

[3]

[3]

-Advantages:

Plasma cutting reduces processing time when compared to autogenous methods. It produces clean cuts with minimal slag and reduces the extent of required post-processing. The equipment is frequently portable and suitable for on-site tasks. In addition, plasma cutting efficiently processes thick materials.

-Applications:

This method is applied in demolition and building projects. It is used in industrial manufacturing, in vehicle repair and restoration, and in shipbuilding. The capacity of plasma cutting to quickly process metal makes it a valuable tool in these sectors.

Further reading: Electrode Materials for Plasma Cutting Machines

4. Oxy-fuel Cutting

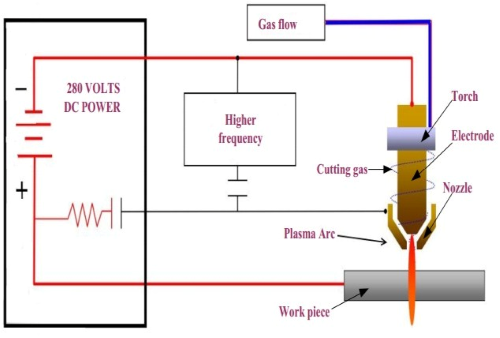

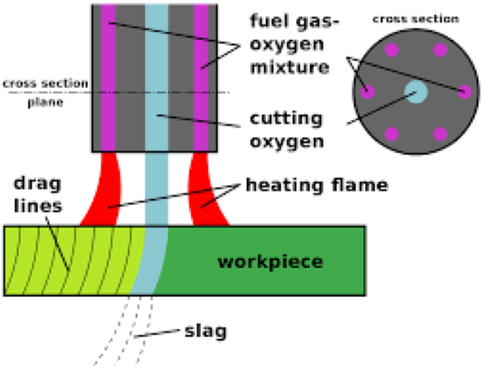

Oxy-fuel cutting, also known as autogenous cutting, employs a mixture of oxygen and fuel gases to cut metal through oxidation and melting. This traditional method continues to be used given its cost efficiency and simplicity in certain applications.

[4]

[4]

-Advantages:

Oxy-fuel cutting is relatively inexpensive in terms of equipment and operating costs. The method is effective for cutting thick steel plates, where other techniques may encounter difficulties. It is simple to operate, requires minimal training and is portable, thereby allowing various cutting tasks.

-Applications:

Oxy-fuel cutting is utilised in heavy industries such as shipbuilding and construction, where thick metal plates require processing. It is also used in metal recycling and recovery operations, given its capacity to dismantle large structures efficiently.

5. Mechanical Cutting (Sawing, Shearing and Milling)

Mechanical cutting encompasses techniques such as sawing, shearing and milling, which physically sever metal using applied force. These methods are regarded for the accuracy and control they offer.

-Advantages:

Mechanical cutting delivers high accuracy and repeatability. The techniques are effective for a wide range of materials and thicknesses. They result in a good surface finish and usually require minimal additional processing. The capacity to precisely control the cutting process is beneficial when producing complex components.

-Applications:

Mechanical cutting is common in metal fabrication companies for producing individual parts and prototypes. It is also employed in manufacturing detailed components and in bespoke metal processing. These techniques are appropriate for applications requiring precise cuts and smooth surfaces.

Conclusion

Each metal cutting procedure has specific advantages that render it suitable for different applications and materials (see Table 1). Laser cutting provides accuracy and speed for detailed designs, while water jet cutting offers versatility without thermal damage. Plasma cutting is selected for its speed and its ability to process thick materials efficiently, and oxy-fuel cutting remains an inexpensive option for heavy-duty tasks. Mechanical cutting methods such as sawing, shearing and milling provide precision and versatility for a variety of metal machining projects.

The choice of method depends on the material type, thickness, the precision required and the specific application requirements. For further information please visit Stanford Advanced Materials.

Table 1: The 5 Main Methods for Effective Metal Machining

|

Method |

Advantages |

Applications |

|

Laser Cutting |

- High accuracy - Fast processing, particularly for thin materials - High edge finish quality - Versatile for various metals |

- Industrial manufacturing - Automotive industry - Aerospace industry - Custom metal fabrication |

|

Water Jet Cutting |

- No heat affected zone (HAZ) - Versatile for various materials - Effective for thick materials - Environmentally friendly |

- Aerospace industry - Automotive sector - Metal art and sculptures - Specialist fabrication businesses |

|

Plasma Cutting |

- Faster processing time - Clean cuts with minimal slag - Portable equipment - Efficient processing of thick materials |

- Demolition and building projects - Industrial manufacturing - Vehicle repair and restoration - Shipbuilding |

|

Oxy-fuel Cutting |

- Inexpensive equipment and operating costs - Effective for thick steel plates - Simple operation - Portable |

- Heavy industry (e.g. shipbuilding, construction) - Metal recycling and recovery operations |

|

Mechanical Cutting |

- High accuracy and repeatability - Versatile for various materials and thicknesses - Good surface finish - Precise control |

- Metal fabrication companies - Production - Bespoke metal processing |

References:

[1] LaserCutter. (27/05/2024). In Wikipedia. https://commons.wikimedia.org/wiki/File:LaserCutter.svg

[2] The Open University. (06/03/2018). Water jet cutting (Hydrodynamic cutting). The Open University. Retrieved on 27/05/2024 from https://www.open.edu/openlearn/science-maths-technology/engineering-technology/manupedia/water-jet-cutting-hydrodynamic-cutting.

[3] Patel, P., & Rana, J.A. (2015). Parametric Analysis of EN8 (AISI 1040) Alloy Steel on Plasma Arc Cutting. International Journal of Science and Engineering Applications, 4, 90–96.

[4] Oxy-fuel welding and cutting. (20/05/2024). In Wikipedia. https://en.wikipedia.org/wiki/Oxy-fuel_welding_and_cutting

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento