Electrode Materials For Plasma Cutting Machines

Introduction

What is plasma cutting? How does the process operate? Which components constitute a plasma cutter? This article provides responses to these queries and presents significant information regarding electrode materials for plasma cutting.

Plasma Cutting Technique: Mechanism and Advantages

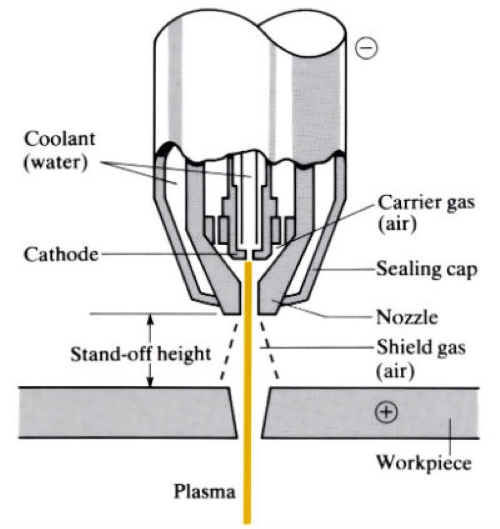

[1]

[1]

Plasma cutting is a method whereby a high-velocity stream of ionised gas, known as plasma, is employed to cut electrically conductive materials. The process involves several key steps:

1. Ignition of the Arc: A high-frequency spark ionises the gas within the plasma torch, thereby creating a conductive channel for the arc.

2. Formation of Plasma: The arc heats the gas to extremely high temperatures, converting it into plasma. The plasma is subsequently expelled at high speed through a nozzle.

3. Cutting of the Material: The extreme heat of the plasma stream melts the material at the cutting interface. Consequently, the high-speed gas stream removes the molten metal and produces a precise cut.

This method yields several advantages over conventional cutting techniques:

- Speed: It operates significantly faster than conventional cutting methods, particularly with thinner materials.

- Precision: It produces clean and precise cuts with minimal heat-affected zones, thereby reducing the need for post-processing.

- Versatility: It cuts a broad range of metals including carbon steel, stainless steel, aluminium, copper and various alloys.

- Cost-effectiveness: It results in lower operating costs compared to other cutting methods, such as laser cutting, given the reduced consumption of consumables and lower maintenance requirements.

Plasma Cutting System: Components and Significance

A plasma cutting system comprises several key components. They operate in combination to execute the cutting process. The principal components are:

1. Power Supply:

The power supply provides the required electrical energy to generate the plasma arc. Its capacity, typically ranging between 30 and 400 amperes, determines the machine’s cutting capabilities.

2. Plasma Torch:

The plasma torch houses the electrode and the nozzle, through which the plasma arc is channelled. It is designed to withstand high temperatures and permits precise control over the cutting process.

3. Electrode:

The electrode generates the arc that ionises the gas to form the plasma. It is an essential component that influences the stability and quality of the plasma arc. Typically, the electrode is constructed from copper with a high-durability insert such as hafnium or tungsten.

4. Nozzle:

The nozzle directs the plasma stream onto the workpiece. It ensures a focused stream at high speed and is composed of materials resistant to high temperatures.

5. Gas Supply:

The gas supply delivers the gas required to generate the plasma, for instance compressed air, oxygen, nitrogen or argon. The selection of the gas affects both the quality and efficiency of the cut and is aligned with the material being processed.

6. Control Panel:

The control panel enables the operator to adjust settings such as current, gas flow and cutting speed. Modern machines incorporate digital interfaces, thereby permitting precise control and ease of operation.

These components function together to generate a high-temperature plasma arc that melts and cuts the workpiece material efficiently and precisely.

Electrode Materials for Plasma Cutting Systems

Electrodes play a central role in plasma cutting systems and directly impact both the cutting performance and the longevity of the equipment. In a plasma cutter, the electrode is located centrally with the nozzle directly beneath it. These two elements are classified as wear parts and must be replaced once significant wear is detected. Worn electrodes, nozzles and swirl rings can produce uncontrolled plasma arcs that may cause severe damage to the torch.

To achieve extended operational life and improved performance, the following materials are principally used for electrodes:

1. Copper:

- Properties: Offers excellent electrical conductivity and effective heat dissipation.

- Usage: Forms the main body of the electrode and provides a base for high-durability inserts.

2. Hafnium:

- Properties: Possesses a high melting point, effective durability and good conductivity.

- Usage: Commonly implemented as an insert at the electrode tip to enhance cutting performance and lifespan.

3. Tungsten:

- Properties: Exhibits a high melting point and satisfactory conductivity.

- Usage: Employed in some electrodes due to its ability to withstand high temperatures.

Advanced Electrode Material: Hafnium Wire

Hafnium Wire:

Recent advancements in electrode materials have demonstrated the advantages of utilising hafnium wire inserts in electrodes. Hafnium wire withstands extreme temperatures due to its high melting point. This property extends electrode life, thereby decreasing the frequency of electrode replacement and minimising downtime. Hafnium electrodes ensure stable arc ignition and maintenance, which results in cleaner cuts and reduces the requirement for frequent replacements. Although the initial cost is higher, the extended lifespan and improved performance contribute to long-term cost savings by lowering the overall operational costs.

Hafnium Wire vs. Zirconium Wire:

1. Performance Differences:

Hafnium wire used in plasma cutting nozzles exhibits good chemical stability and resistance to corrosion. Its high melting point ensures the stability of the cutting nozzle, thereby preventing melting and deformation. In contrast, zirconium wire is prone to oxidation and corrosion and tends to expand under high temperatures, which can lead to deformation of the nozzle and subsequent damage.

2. Application Scenarios:

Hafnium wire is suitable for high-precision cutting applications that require high chemical stability and resistance to corrosion. It is preferred for cutting materials that are difficult to process. Zirconium wire is generally employed in less demanding cutting tasks, such as processing copper and aluminium, where the requirements for durability and stability are lower. [2]

Conclusion

Plasma cutting systems are essential tools in modern metal processing. They deliver rapid and precise cuts across a wide range of materials. The selection of electrode material is crucial for the operational performance and efficiency of these systems. Recent advancements, such as the use of hafnium wire, have improved plasma cutting technology by producing cleaner cuts, extending electrode life and reducing operational costs. An understanding of the importance of high-quality electrode materials and current technological developments enables the achievement of optimal results in cutting operations. Further information is available at Stanford Advanced Materials (SAM).

References:

[1] The Open University. (2018). Plasma arc cutting. The Open University. https://www.open.edu/openlearn/science-maths-technology/engineering-technology/manupedia/plasma-arc-cutting

[2] Xu, S. (2005). Zirconium-Hafnium Wire Processing and its Application in Plasma Cutting Electrodes. Chinese Journal of Rare Metals. https://www.cqvip.com/qk/93288x/200501/15443902.html

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento