2 Different Ways To Produce Hyaluronic Acid And Its Applications

Introduction

Hyaluronic Acid (HA), also known as Hyaluronan, is a linear polysaccharide discovered in 1918 by Karl Meyer and John Palmer [1]. In this article, a brief introduction is provided regarding the nature of hyaluronic acid, its production methods and its applications.

What is Hyaluronic Acid?

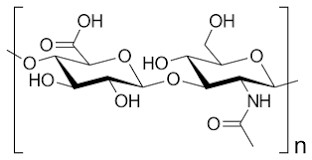

Hyaluronic acid (HA) is a linear glycosaminoglycan composed of repeating disaccharide units of glucuronic acid and N-acetylglucosamine. See Figure 1. A typical HA molecule may exhibit the structure shown in Figure 1 more than 10 000 times [2].

Figure 1: Structure of a hyaluronic acid monomer: Glucuronic acid is presented on the left and N-acetylglucosamine on the right.

HA is commonly located in the extracellular matrix of epithelial, neural and connective tissues of vertebrates. It is also present in certain microorganisms, such as streptococci, as part of their extracellular capsule. In these microorganisms, HA serves both as a protective agent and as a barrier that interferes with recognition by the host immune system during infection [2].

Owing to its high water-binding capacity and established biocompatibility, hyaluronic acid is used in numerous applications within biomedical pharmaceutics, cosmetics and clinical investigations. HA is capable of absorbing large quantities of water and functions as a lubricant and shock absorber in joints and connective tissues. Given its repetitive structure, variations in chain length result in quantifiable differences in properties, thereby enabling a range of applications. Consequently, demand for HA has increased steadily since its discovery. Two approaches have been developed to produce HA efficiently and cost-effectively.

How is Hyaluronic Acid Produced?

Currently, two main sources are utilised for the production of hyaluronic acid: animal and bacterial sources. Let us first consider hyaluronic acid obtained from animal sources.

Hyaluronic Acid Obtained from Animal Sources

Hyaluronic acid was first isolated in 1934 by Meyer and Palmer from the vitreous humour of bovine eyes. Subsequently, various animal tissues such as rooster combs, human umbilical cords and bovine synovial fluid have been employed for its extraction. The overall process comprises the homogenisation of the animal tissue, extraction, purification and formulation of the final product [1]. Different extraction and purification methods are applied depending on the raw material and the desired quality of the HA product. For example, see high-purity HA for medical purposes.

Washing: Prior to extraction, the animal tissue is cleaned using a mixture of ethanol and chloroform, or with water, acetone and ethanol. For instance, rooster combs are collected and subjected to treatment in 95% ethanol that has been saturated with chloroform for one day. This washing step is repeated until the wash solution appears transparent and colourless. This procedure removes undesirable components such as iron, copper and phosphate ions, given that HA may be oxidised or degraded by these ions.

Extraction: The pre-treated animal tissue is then extracted with a mixture of water and chloroform in a 20:1 ratio. The mixture is stirred at least twice to extract as much HA as possible. The extraction solution is allowed to stand for a minimum of 24 hours at temperatures between 4 and 25 °C. The mixture is filtered, and a 1:1 mixture of chloride and chloroform is added, followed by stirring for 3 to 5 hours at temperatures between 4 and 25 °C.

Purification: Because the HA extracted from animal tissue contains various impurities, such as proteins, lipids, peptides and low-molecular-weight precursors, simple washing with organic solvents is insufficient. Therefore, proteolytic enzymes are added to the extract at its natural pH and the solution is stirred for 5 days at room temperature. The aqueous phase is then collected and passed through a Teflon filter for sterilisation. Three volumes of ethanol are added to precipitate the polysaccharide. Finally, the polysaccharide undergoes an additional precipitation with ethanol and acetone, is sterilised with acetone and dried under vacuum [1].

The final HA product has a molecular weight exceeding 750 000 Da. The production efficiency is approximately 0.8 g of hyaluronic acid per 1 kg of rooster combs.

Hyaluronic Acid from Bacterial Sources

Hyaluronic acid produced from bacteria has experienced rapid development over the past two decades. A few gram-positive bacteria, such as certain strains of Streptococci or Pasteurella, can be used for HA production. These bacteria typically must meet the following criteria:

- The bacteria should be non-toxic and not harmful to humans, and must be non-haemolytic.

- The bacteria must not exhibit hyaluronidase activity against HA. HA is a long-chain compound with a simple repetitive structure that can be readily degraded under mechanical, thermal, chemical and enzymatic conditions.

- High production efficiency is also an important consideration.

Streptococci from groups A and C are frequently employed for HA production due to their high yield. However, these strains also produce toxins. Given that the gene sequence responsible for HA biosynthesis has been identified, many bacteria (Bacillus, Agrobacterium, E. coli, Lactococcus) can be genetically modified to express the gene and produce HA. Consequently, non-haemolytic and hyaluronidase-negative bacteria are selected and their gene sequences are modified to enable HA production [2].

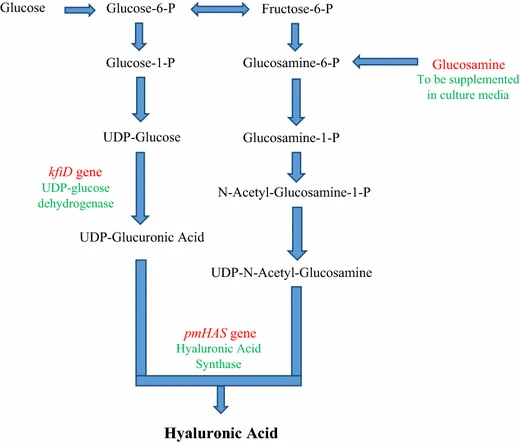

The overall process for obtaining hyaluronic acid from bacterial sources is complex. Figure 5 illustrates the production of HA by the bacterium E. coli [2].

Figure 5: An overview of the biosynthetic pathways utilised by E. coli to produce hyaluronic acid [2].

Applications of Hyaluronic Acid

The applications of hyaluronic acid depend on its molecular size: high molecular weight (approximately 1 000 to 1 500 kDa), medium molecular weight (approximately 200 to 800 kDa) and low molecular weight (approximately 5 to 200 kDa).

High-molecular-weight hyaluronic acid (HMW-HA) is typically used in skincare products to provide surface hydration. Due to its large molecular size, it does not penetrate deeply into the skin; rather, it forms a film on the surface which prevents water loss and maintains hydration. This type of HA is commonly incorporated into moisturising creams, sheet masks and other hydration products.

Low-molecular-weight hyaluronic acid (LMW-HA) can penetrate more deeply into the skin. Consequently, it is used in anti-ageing skincare products where it may assist in stimulating collagen production and improving the structural integrity and appearance of the skin. It is also utilised in serums and other formulations that are rapidly absorbed.

For further information, please refer to: High- vs. low molecular weight hyaluronic acid

Medium-molecular-weight hyaluronic acid (MMW-HA) has an intermediate molecular size. This variant is less commonly used in skincare formulations; however, it is considered beneficial for both surface hydration and deeper skin penetration. It may be incorporated into formulations designed to provide both immediate and sustained hydration.

In addition to its use in topical skincare products, hyaluronic acid is employed in injectable treatments such as dermal fillers. Typically, these fillers combine high and low-molecular-weight hyaluronic acid to provide immediate volumetric enhancement and hydration, along with longer-lasting volumising effects.

Overall, the various applications of hyaluronic acid depend on its molecular size and the specific skincare issues being addressed. High-molecular-weight HA is appropriate for superficial hydration, while low-molecular-weight HA is beneficial for anti-ageing and collagen stimulation. Medium-molecular-weight HA, although less frequently used, may contribute to both surface and deeper hydration.

Conclusion

In summary, hyaluronic acid can be extracted from both animal and bacterial sources. HA products are manufactured in various molecular sizes to address distinct applications in skincare.

Stanford Advanced Materials has extensive experience in the production and distribution of high-, medium- and low-molecular-weight hyaluronic acid. It is important to select a product that is appropriately formulated and suited to your specific skincare requirements in order to achieve the desired outcomes. For further details, please visit our homepage.

References

- Polyak, F., Khabarov, V. N., Boykov, P. Y. and Selyanin, M. A. (2015). Hyaluronic acid: Production, properties, application in biology and medicine. John Wiley & Sons, Incorporated.

- Sze, J. H., Brownlie, J. C. and Love, C. A. (2016). Biotechnological Herstellung von Hyaluronsäure: ein kleiner Überblick. 3 Biotech, 6(1), 67. https://doi.org/10.1007/s13205-016-0379-9

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento