3D Printing Powder: What Is It & How Is It Used?

3D printing, a more commercial term for Additive Manufacturing (AM), was first mentioned by Murray Leinster in the 1940s. Although 3D printing accounts for less than 1 % of the global manufacturing market, its scale doubles every three years due to quantifiable advantages over conventional methods. The global 3D printing market is anticipated to increase at an annual rate of 20.8 % between 2022 and 2030 [1]. Its extensive application in healthcare, the automotive sector, aerospace and defence confirms its growing adoption.

3D printing comprises seven methods: vat photopolymerisation, material jetting, material extrusion, binder jetting, powder bed fusion, sheet lamination and directed energy deposition. The latter four methods all employ 3D printing powder as the primary feedstock.

What is 3D Printing Powder?

3D printing powder refers to the particulate material used in 3D printing. Typically it is composed of metal, an alloy, ceramics or a polymer.

3D printing powder is classified into two groups based on its morphology: spherical and irregular. Spherical powder exhibits enhanced flowability. Consequently, it can distribute evenly and form uniform layers that yield stable components. However, spherical powder is more expensive than its irregular counterpart.

How is 3D Printing Powder Produced?

Most methods for producing 3D printing powder rely on atomisation techniques, including water atomisation and gas atomisation.

Water Atomisation (WA)

The atomisation begins with melting the base metal or alloy in a furnace. The molten material is held for a period to ensure complete homogenisation. It is then transferred into a refractory crucible fitted with a controllable nozzle. Once the nozzle is opened, the molten liquid enters the atomisation chamber and falls freely. High-velocity water jets cool, atomise and condense the droplets. Finally, the powder is collected from the chamber floor and subsequently dried. The powder produced by water atomisation is generally irregular and is not utilised in 3D printing.

Gas Atomisation (GA)

Gas atomisation is similar to water atomisation except that a high-pressure inert gas stream is used to atomise the molten liquid. Given that the specific heat capacity of gas is lower than that of water, the droplets require a longer time to cool and solidify. Consequently, the powder produced tends to be spherical. The particle diameter is difficult to control and typically ranges from 0 to 500 μm. Despite the usage of inert gas in all steps, contamination may occur during the transfer of molten material from the furnace to the crucible or during other stages.

Electrode Induction Melt Gas Atomisation (EIGA)

Developed on the basis of gas atomisation, this process uses rotating metal rods as the raw material, which are melted by induction heating. The molten rods fall directly into the atomisation chamber. With the EIGA method, it is possible to produce powder with a narrower particle size distribution. This technique is increasingly applied in the production of active alloy powders such as Ti-6Al-4V.

Plasma Atomisation (PA)

Plasma atomisation employs plasma as the heat source to melt the raw material, which is provided in powder or wire form. As the material passes through the plasma, it is melted and atomised simultaneously by inert gas jets. The subsequent steps follow those of gas atomisation. This method is capable of producing powder that is both more spherical and finer.

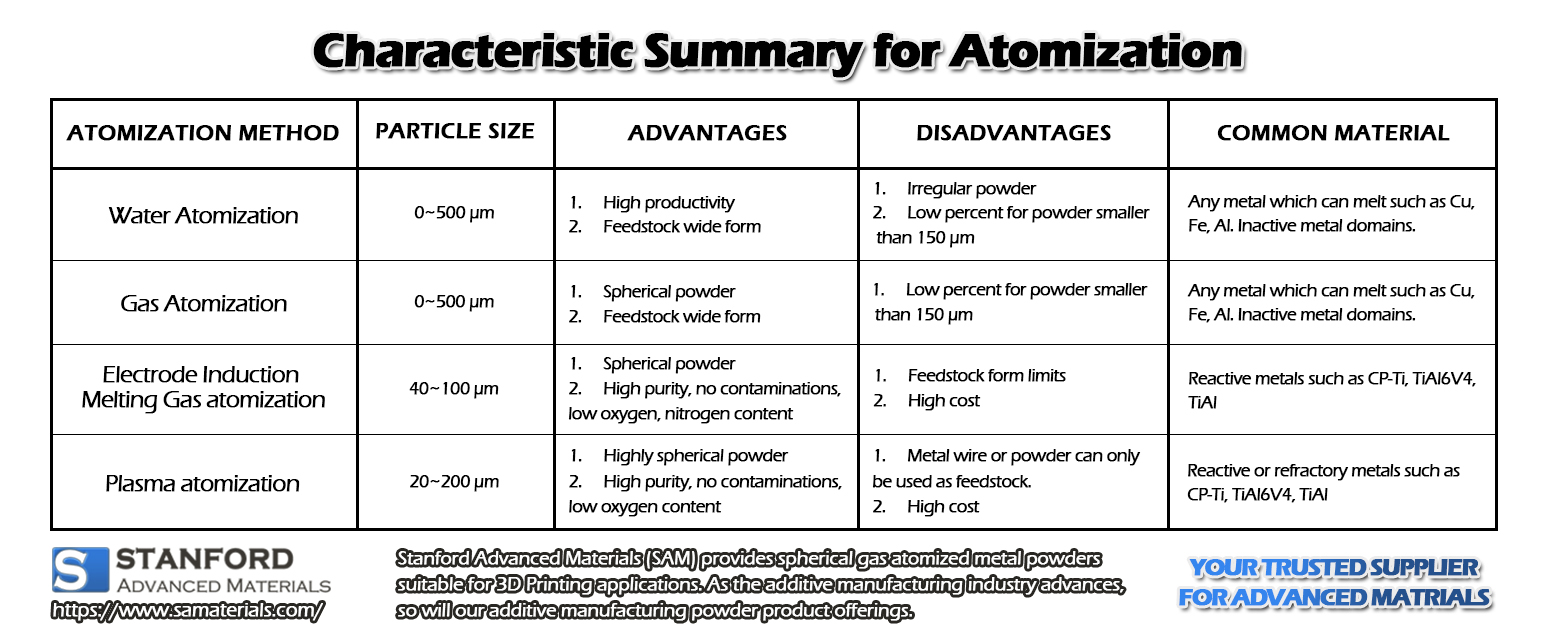

Table 1 presents an overview of the four atomisation methods described above.

How is 3D Printing Powder Utilised?

3D printing powder is primarily used in powder bed-based 3D printing technologies such as powder bed fusion and binder jetting. The fundamental process involves the layer-by-layer construction of components using the powder. This approach enables the production of more intricately detailed and custom components compared to conventional techniques.

A recoater retrieves the powder (typically spherical metal or polymer powder, for example, spherical titanium powder) from the supply system and applies a thin, even layer onto the build plate. Subsequently, a laser selectively melts the powder. Once a thin layer has been processed, the build platform is lowered by one layer height and the supply system raises the powder by an equivalent amount, thereby repeating the process. This procedure is referred to as powder bed fusion.

Another technique employs a binder to join the powder particles. Other processes resemble powder bed fusion. This approach is known as binder jetting.

The powder serves as the primary material spread onto the build plate to form a thin layer. The parameters of the powder are critical in achieving components with high detail and hardness. Irregular powder does not form uniform and high-density layers. This may result in components with lower density even if the print process is interrupted. Although spherical powder performs better in terms of layer uniformity, its cost is higher. Powders with smaller particles allow for thinner layers, thus requiring a greater quantity of powder for the same layer thickness. These layers are finer and more sensitive compared to those formed with larger particles. For powders with a particle size below 20 μm, caution is necessary because they are prone to agglomeration and may form uneven layers. Special techniques are required when using such fine powders.

Further information is available on the Stanford Advanced Materials Homepage.

Reference

1. 3D Printing Market Size & Share Report, 2022-2030. (n.d.). Retrieved on 07/12/2022, from https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento