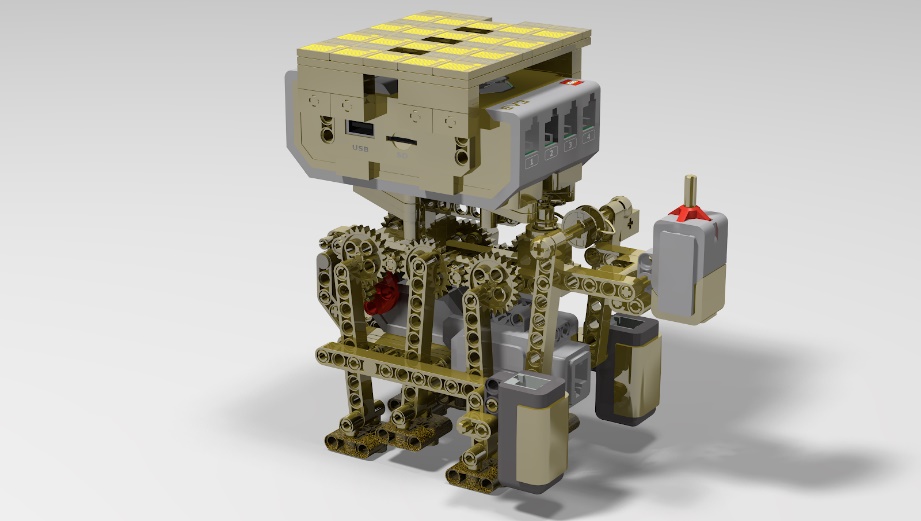

Previous Projects - Prototype Moveable Robot

This article explains a project from my ENED (Engineering Education) course. A team of engineering students designed a prototype movable robot (PMR). The PMR is required to load a specific material, determine its weight and deliver it to a designated disposal station within a facility. We submitted a paper prototype for the class. Physical construction was not feasible given the COVID‐19 pandemic. Consequently, the team investigated the properties of the selected materials and their effects on the final design.

During our technical coursework, we were instructed to use rendering software called BrickLinks. BrickLinks allows constructions with LEGO bricks to be visualised as images. The prototype, if built, would consist of LEGO bricks. All LEGO bricks and parts are manufactured from Acrylonitrile Butadiene Styrene (ABS).1. The robot must be lightweight so that a motor on its back operates efficiently and strong enough to support material containers for weight determination. Additionally, the PMR legs must negotiate obstacles and rubber tyres were not permitted. Consequently, our team selected a LEGO rubber component without a central axle. LEGO utilises a rubber product that has a chemical composition equivalent to that used in commercial tyres.2. It consists of Butadiene Rubber, Styrene Rubber and Natural Rubber.3. We manufactured the PMR feet from rubber to improve stability on uneven surfaces and difficult terrain. Moreover, the feet are mounted on rotatable bearings, enabling them to move forwards and backwards, thereby maintaining a secure stance under adverse conditions.

To explain the design: the PMR follows a painted line on the warehouse floor. Two light sensors detect when a turn is required. This navigation method was mandated rather than selected by our team. The robot’s control unit is housed within a LEGO console mounted on its back and serves as the motor for the six legs. A pulley system at the front lifts the material containers. The design is based on an analysis of arachnid locomotion and leg mechanics, in accordance with the course guidelines.

Above is the final rendering of the robot produced with BrickLinks software. The robot is constructed from a material that supports both the servo and motor at its top and the two light sensors at its front lower portion. The material must also be flexible enough to support the front pulley system. This system can move fully in vertical and horizontal directions to load material containers, measure their weight and transport them to the target. Standard LEGO plastic satisfies these technical requirements, allowing construction without specialised components or 3D‐printed parts, except for the feet. The plastic is appropriate for the chassis and pulley disc but is inherently rigid and lacks elasticity. Therefore, LEGO plastic is inadequate for the feet on uneven or difficult terrain. Consequently, the team employed an advanced material that offers increased flexibility. The chosen component for the robot legs was produced in LEGO tyre rubber with reduced dimensions. This part requires custom manufacturing, is relatively small and only six units are needed. The foot components are attached to an axle that rotates nearly 90°; thereby the robot can adjust its stance when encountering uneven surfaces or obstacles.

The advanced materials used in this project were a mixture of synthetic and natural rubber combined with ABS plastic. The plastic contributed to the rigidity of the robot body while providing flexibility for the lifting system. The rubber was employed to enhance traction and provide the capability to traverse challenging terrain effectively.

Bibliography:

- Pickering, David (1999). Das ultimative LEGO Buch. New York: Dorling Kindersley. ISBN 0-7894-4691-X.

- Threewitt, C. (11/09/2020). Sie werden nie erraten, welches Unternehmen die meisten Reifen der Welt herstellt. https://entertainment.howstuffworks.com/lego-tires.htm.

- S. Tire Manufacturers Association. (2020). Was in einem Reifen steckt. What's In a Tire | USTMA. https://www.ustires.org/whats-tire-0#:~:text=Die%20zwei%20wichtigsten%20synthetischen%20Gummis,in%20Kombination%20mit%20natürlichem%20Gummi.

Note: This article is a submission for the Stanford Advanced Materials College Scholarship 2021.

Juan Ignacio Alvarado

Stanford Advanced Materials Scholarship

University of Cincinnati

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento