An Introduction To Hard Facing Materials

Introduction

In the field of industrial operation and maintenance, longevity is not only a required attribute but a necessity. A key strategy to extend equipment service life is hardfacing, a process that significantly increases the wear resistance of machinery surfaces.

This article examines the concept, advantages, materials employed, the application process and common applications across various sectors.

What is Hardfacing?

Hardfacing is a welding process in which a layer of wear‐resistant material is applied to the surface of a metal component or piece of equipment. This technique protects against abrasion, impact, erosion and other forms of damage that components experience in demanding operating environments.

By applying a hard layer onto a softer base metal, the process increases the service life of critical components and thereby reduces the need for frequent replacements and downtime.

The wear‐resistant material refers to a specific type of alloy or composite applied to a softer base metal. Common materials include carbides (such as Tungsten Carbide and chromium carbide), metal alloys (including nickel‐based, cobalt‐based and iron‐based alloys) and metal matrix composites (MMC), which combine metal with hard particles. The selection of the hardfacing material depends on the specific wear requirements and operating conditions.

What are the Advantages?

Hardfacing materials provide several important benefits in industrial settings. The primary advantages are:

- Extended component lifespan: Hardfacing increases the life of parts that are subject to abrasion, impact or corrosion. This reduces the frequency of replacements or repairs.

- Cost savings: Longer-lasting parts reduce the requirement for new purchases and limit work stoppages for repairs, thereby cutting costs on spare parts and labour.

- Improved performance: Components with hardfacing maintain their shape and operating properties for an extended period.

- Customised protection: Hardfacing may be adjusted to meet the specific requirements of equipment. This includes the type of wear, such as scratches, erosion or impacts, and the operating conditions.

Which Hardfacing Materials are most commonly used in the Industry?

The primary hardfacing materials selected in industry are those that offer high wear resistance and durability in demanding conditions. They contribute to extended equipment life and lower maintenance costs. Common types include:

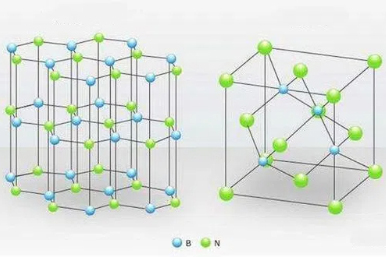

1. Carbides:

- Tungsten Carbide is extremely hard and exhibits high resistance to abrasion. It is frequently used in the mining industry for drilling and cutting.

- Chromium carbide demonstrates high wear resistance, particularly at elevated temperatures. It is suitable for environments with significant corrosion and oxidation.

2. Alloys:

- Nickel‐based alloys offer high corrosion resistance and are appropriate for high temperature conditions and environments where corrosive substances are present.

- Cobalt‐based alloys (Stellite) retain hardness at high temperatures. They are used for cutting tools and engine components.

- Iron‐based alloys are a more cost‐effective option. They provide acceptable wear resistance and can withstand various types of wear.

3. Metals and Metal Matrix Composites (MMCs):

- Bronze and brass are used owing to their resistance to sliding wear. They are commonly applied on bearing surfaces and bushings.

- Metal matrix composites combine metal with hard particles, such as carbides. This composition results in a balance between toughness and wear resistance.

Each material is selected based on the application requirements, including the type of wear (abrasion, impact, erosion etc.), the operating environment (temperature and presence of corrosive substances) and the mechanical properties required. Stanford Advanced Materials (SAM) is a reliable supplier in this field. Stanford Advanced Materials (SAM) provides high‐quality hardfacing materials and customised solutions to extend the life of your equipment.

Table 1. Common Hardfacing Materials

|

Types |

Examples |

Properties |

|

Carbides |

- Chromium Carbide |

- High hardness - High wear resistance - Good performance at elevated temperatures |

|

Alloys |

- Nickel‐based alloys - Cobalt‐based alloys (Stellite) - Iron‐based alloys |

- Corrosion resistance (Nickel) - Retains hardness at high temperatures (Cobalt) - Versatile wear resistance (Iron) |

|

Metals and MMCs |

- Bronze and Brass |

- Resistance to sliding wear (Bronze, Brass) - Balance between toughness and wear resistance (MMCs) |

How are Hardfacing Techniques Applied?

The process may be performed by various welding techniques. The key methods are:

- Deposition Welding: This method applies hardfacing material using welding processes such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW) or flux-cored arc welding (FCAW). It is a versatile method that is applied to a wide range of components.

- Thermal Spraying: In thermal spraying, including plasma spraying and high velocity oxygen fuel spraying (HVOF), the material is applied in a molten or semi-molten state. This method is ideal for applying coatings with minimal thermal impact on the substrate.

- Laser Deposition Welding: A high-intensity laser is used to melt the material, which then bonds with the base metal. This method ensures precise control and minimal dilution between the coating and the substrate, thereby achieving a high-quality finish.

How are Hardfacing Materials Used?

Hardfacing materials are employed in a range of industrial sectors that benefit from increased durability. Their applications include:

- Mining and Construction: Equipment such as drills and shovels are hardfaced to withstand abrasion and impact wear from rock, minerals and construction materials.

- Oil and Gas: Components such as drill bits, valves and pump impellers are protected against wear and corrosion, thereby ensuring reliability in demanding environments.

- Agriculture: Agricultural machinery, including ploughshares and combine harvester knives, receives a hard coat to resist wear from soil and harvested materials, thus extending operational life.

- Manufacturing: Tools and moulds are frequently hardfaced to maintain dimensional accuracy and surface quality, which are essential for the production of high-quality products.

Conclusion

Hardfacing is a key technology for maximising machine lifespan. By selecting appropriate hardfacing materials and processes, industry can significantly extend component service life, reduce maintenance costs and ensure continuous production. Advances in material science and welding technology have increased the potential for these materials to contribute to industrial sustainability and productivity.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Chin Trento

Chin Trento