Advancements In Porous Silicon Carbide Materials For Catalytic Applications

Description

Porous silicon carbide materials have become an essential component in catalytic processes. These materials exhibit considerable strength and resist high temperatures. They also possess an extensive surface area. The pore network enables catalysts to adhere more effectively and operate at an increased rate. This article provides a succinct overview of recent advances.

Introduction to Porous Silicon Carbide

Porous silicon carbide is manufactured using specialised techniques that generate minute pores throughout the material. These pores increase the surface area available on catalyst supports. The pore sizes range from a few nanometres to several micrometres. This range assists in various catalytic reactions. The material is recognised for its hardness and strength, even when subjected to temperatures frequently exceeding 1 200 °C.

Incremental improvements in these materials have been realised over the past ten years. Researchers have worked to control the pore formation process. They aim to achieve uniform pore size and high porosity. Multiple studies have reported a porosity of up to 60 per cent while maintaining strength. This porous silicon carbide has been employed in catalysts for motor vehicles and in chemical processing plants. In these applications, the porous structure increases the available active sites for reactions.

Related Cases

Several cases have demonstrated that catalysts supported on porous silicon carbide exhibit increased long-term stability. A study in chemical laboratories revealed that the developed porous structure reduced catalyst deactivation by 20 per cent compared to older supports. In another instance in the petrochemical industry, reaction downtime decreased upon the use of these materials. Consequently, the formation of by-products was lowered, thereby increasing overall yield. These data are pertinent for researchers in catalysis.

Production Methods for Porous Silicon Carbide

The production process typically incorporates template techniques combined with thermal treatments. A common method employs preformed templates that burn out during high-temperature sintering. This process leaves a network of interconnected pores. The method requires precise temperature control. Such control was not achievable with older techniques. The new methods provide a reliable procedure to produce consistent materials. The resulting porous network remains intact even under challenging conditions.

Benefits and Properties

Furthermore, the material exhibits favourable chemical resistance. It retains its integrity in corrosive atmospheres. Conditions such as those encountered in flue gas cleaning are common in industrial operations. Porous silicon carbide supports handle acids and alkalis more effectively than many other materials. In practice, this results in catalysts requiring less maintenance in industrial plants.

Another property of porous silicon carbide is its lower weight compared with other high-temperature ceramics. This characteristic offers an advantage in weight savings. In industries such as aerospace and transport, every gram is important. The ability to reduce weight without compromising strength benefits manufacturers. The consistency and improvement of these materials result from years of joint research in laboratories and workshops.

The development of these materials does not rely on a single discovery. It is a cumulative process that benefits several industrial sectors. In catalytic applications, the porous structure facilitates a more efficient progression of reactions. The uniform distribution of pores creates a substantial active volume for reactions. Owing to these properties, industries can safely lower operating temperatures while increasing yield. Consequently, energy consumption and overall costs are reduced.

Conclusion

Recent progress in the manufacture of porous silicon carbide for catalytic applications is notable. The material now exhibits high porosity, strength and resistance to both heat and chemicals. Data and practical examples demonstrate that these advances enhance catalytic performance across industries ranging from automotive to petrochemistry. Further information is available at Stanford Advanced Materials (SAM).

Frequently Asked Questions

Q: What advantages do porous silicon carbide materials offer in catalysts?

Q: They provide an extensive surface area, improved thermal stability and chemical resistance.

Q: What are the typical pore sizes in this material?

Q: The pore sizes range from a few nanometres to several micrometres.

Q: In which industries are these materials most commonly used?

Q: They are employed in automotive catalysts and petrochemical processing plants.

Reference:

[1] Tuci, Giulia & Liu, Yuefeng & Rossin, Andrea & Guo, Xiangyun & Pham, Charlotte & Giambastiani, Giuliano & Pham-Huu, Cuong. (2021). Poröses Siliziumkarbid (SiC): A Chance for Improving Catalysts or Just Another Active-Phase Carrier? Chemical Reviews. 121. 10.1021/acs.chemrev.1c00269.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

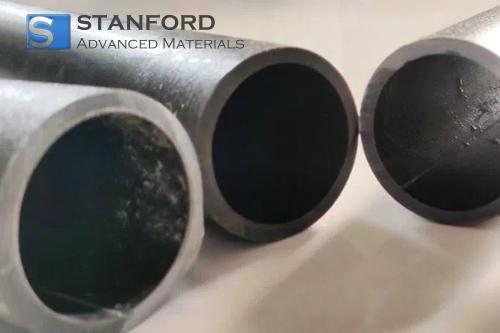

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento