Ceramics 101: A Beginner's Guide

Description

Ceramics are solid inorganic compounds. They are typically produced by forming and heating natural or synthetic raw materials at high temperatures. Historically significant, ceramics are now utilised for their durability, heat resistance and electrical insulation properties in technology, medicine, electronics and consumer products. Modern ceramics have diversified into various technical types, including aluminium oxide, zirconium dioxide, boron nitride and boron carbide, each characterised by defined properties and industrial applications.

-What are Ceramics

Ceramics are non-metallic and inorganic materials. They are hardened by heating. They are generally manufactured from natural clay, minerals and other raw materials and subsequently fired at high temperatures to achieve strength and durability.

-Types of Ceramics

- Traditional Ceramics – This category comprises pottery, tiles and bricks made from clay-based materials.

- High-Performance Ceramics – Developed for specialised industrial and technological applications, for example in biomedical implants, aerospace components and semiconductor devices.

- Refractory Ceramics – Utilised in high-temperature environments such as furnaces, owing to their heat resistance.

- Glass Ceramics – A hybrid material that exhibits properties of both glass and ceramics, used in cookware and electronics.

-Properties of Ceramics

- High Heat Resistance – Capable of withstanding extreme temperatures, thereby serving applications in furnaces and aerospace.

- Hard and Brittle – They exhibit high compressive strength but may fracture when subjected to impact.

- Chemical and Corrosion Resistance – They do not rust and do not degrade easily when exposed to chemicals.

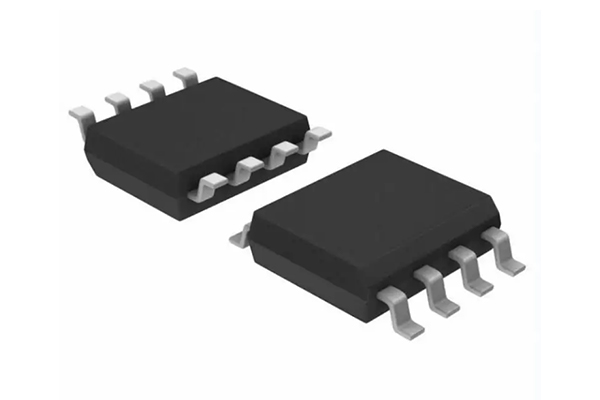

- Electrical Insulation – Their non-conductive properties make them suitable for electronic applications.

- Aesthetic Versatility – Employed in decorative pottery, tiles and fine porcelain.

-Applications of Ceramics

- Construction – Used in bricks, tiles and cement for building purposes.

- Electronics – Incorporated in insulators, capacitors and semiconductor components.

- Medical – Applied in dental implants, bone replacements and prosthetic devices.

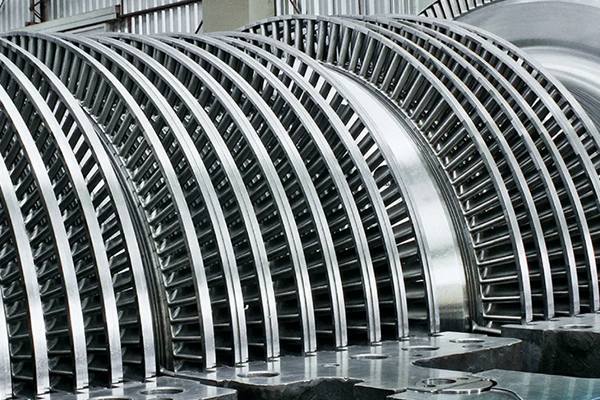

- Aerospace & Automotive – Utilised in heat-resistant coatings, engine parts and aerospace components.

- Art and Household Goods – Found in pottery, tableware and decorative ceramics.

Aluminium Oxide

Aluminium Oxide, chemically known as alumina (Al₂O₃), is defined by its high hardness, wear resistance and thermal stability. Alumina ceramics offer excellent electrical insulation, which is important in electronic devices and insulators. Their resistance to chemical attack makes them suitable for chemical processing equipment and corrosion‐resistant components. In addition, aluminium oxide is frequently used in biomedical applications, such as hip joint replacements, owing to its biocompatibility and mechanical reliability.

Zirconium Dioxide

Zirconium Dioxide (ZrO₂) is noted for its enhanced toughness and strength, which exceed those of many conventional ceramics. It is sometimes referred to as “ceramic steel”. It is employed in applications that require resistance to cracking and impact, for instance in cutting tools and dental implants. Its high thermal expansion and effective insulation properties render it suitable for thermal barrier coatings in turbine engines, as well as for use in jewellery and decorative products.

Boron Nitride

Boron Nitride (BN) is occasionally called “white graphite”. Its structure is analogous to that of graphite. It primarily functions as an electrical insulator. Boron nitride ceramics demonstrate excellent thermal conductivity, electrical insulation and chemical inertness. These properties facilitate their use in heat sinks, high-temperature lubricants and insulating components within electronic devices. Their capacity to endure thermal shocks supports their application in aerospace components and refractory linings.

Boron Carbide

Boron Carbide (B₄C) is one of the hardest ceramic materials, exceeded only by diamond and cubic boron nitride. Its high hardness and wear resistance make it suitable for ballistic protection, abrasive materials and cutting tools. Its low density coupled with high hardness has led to its use in ballistic armour and shielding applications within aerospace.

Table of Properties and Applications

The following table provides an overview of the key properties and primary applications for the ceramic materials discussed:

|

Ceramic Material |

Density (g/cm³) |

Hardness (Mohs) |

Thermal Conductivity (W/m-K) |

Primary Applications |

|

Aluminium Oxide |

3.95 |

9 |

30 |

Electrical insulation, biomedical implants, chemical equipment |

|

Zirconium Dioxide |

5.68 |

8 |

2 |

Cutting tools, dental implants, jewellery, thermal coatings |

|

2.25 |

2 |

600 |

Electrical insulation, heat sinks, lubricants, aerospace components |

|

|

2.52 |

9.5 |

30 |

Ballistic protection, abrasives, cutting tools, aerospace shielding |

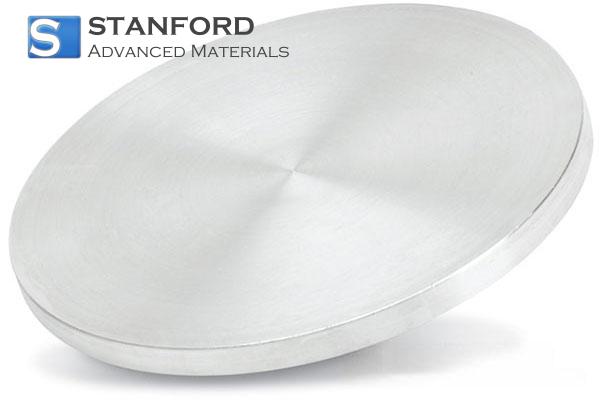

Additional information can be found at Stanford Advanced Materials (SAM).

Frequently Asked Questions

1. How are ceramics manufactured?

Ceramics are produced by shaping raw materials such as clay and firing them at high temperatures, thereby hardening and strengthening the material.

2. What is the difference between traditional and modern ceramics?

Traditional ceramics, such as pottery and tiles, are used for everyday applications, whereas high-performance ceramics are developed for specialised uses such as biomedical implants and aerospace components.

3. Why are ceramics brittle?

Ceramics exhibit a fixed molecular structure with strong bonds; given that they lack flexibility, they may fracture when subjected to impact.

4. How are ceramics commonly used in daily life?

Ceramics are incorporated in kitchenware, tiles, electrical insulators, biomedical implants and smartphone screens.

5. Are ceramics environmentally sustainable?

Many ceramics are manufactured from natural materials and possess extended lifespans. Consequently, they contribute to sustainable material usage despite some energy-intensive processing steps in industrial production.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento