Comparative Study Of Niobium Titanium With Niobium Tin For Superconducting Applications

Description

The article provides a detailed overview of Niobium-Titanium and Niobium-Tin. It compares their physical and superconducting properties. The discussion focuses on practical applications such as Magnetic Resonance Imaging and particle accelerators.

Advantages and Disadvantages

Niobium-Titanium is a well-known superconducting alloy. Its use is based on its ductility and reproducible performance. It exhibits a critical temperature of approximately 9 Kelvin and can withstand magnetic fields up to approximately 10 Tesla. Its manufacturing process is simple, thereby allowing engineers to draw it into wires and coils with ease.

In contrast, isNiobium-Tin an intermetallic compound. It exhibits superconducting properties that suit high-energy applications. Niobium-Tin typically has a critical temperature near 18 Kelvin. It is rated to operate in magnetic fields of 20 to 30 Tesla. Consequently, it is utilised in particle accelerators and fusion reactors where high magnetic fields are required. Manufacturers must apply a heat treatment process to convert the precursor materials into a superconducting phase. This reaction heat treatment requires careful control of temperature and duration to achieve the correct intermetallic structure.

Further reading: Types of Superconducting Materials and Their Applications

How to Choose: Niobium-Titanium versus Niobium-Tin

The selection between these two materials depends on the application. If flexible and ductile superconducting wires are required, Niobium-Titanium is often chosen. Its manufacturing procedure is relatively simple and its superconducting performance is sufficient for many applications, for example in MRI systems.

Conversely, Niobium-Tin is indicated when higher magnetic fields are necessary. In the construction of magnets for fusion reactors, its high critical magnetic field compensates for its brittleness. Research laboratories for high-field magnets use controlled heat treatments to yield superconductors from Niobium-Tin that meet high field requirements.

Technicians benefit from the formability of Niobium-Titanium. It can be twisted and bent without losing its superconducting properties. This quality is important for devices that require long wires with minimal energy loss. In contrast, the stiffness of Niobium-Tin requires that its shape be fixed during manufacture. Typically, it is cast or wound first and then subjected to a controlled heat treatment.

Engineers face different challenges with each material. The simple manufacturing process of Niobium-Titanium permits mass production and lower costs in applications such as MRI systems. The more complex processing of Niobium-Tin increases production costs. Consequently, it is used selectively in projects that demand higher performance. Examples include superconducting magnets for research reactors and modern accelerators, where performance under high magnetic fields is critical.

The comparison between Niobium-Titanium and Niobium-Tin is significant in superconductivity. Each material exhibits properties favourable for specific applications. Differences in mechanical properties, superconducting temperatures and magnetic field tolerances determine their appropriate use. It is essential that engineers, materials scientists and application specialists are aware of these differences to select the correct material for their superconducting projects.

Summary Table

|

Feature |

Niobium-Titanium |

Niobium-Tin |

|

Critical temperature |

Approximately 9 Kelvin |

Approximately 18 Kelvin |

|

Critical magnetic field |

Approximately 10 Tesla |

20 to 30 Tesla |

|

Mechanical properties |

Ductile and formable |

Brittle; requires careful handling |

|

Manufacturing process |

Simple warm drawing |

Complex; requires reaction heat treatment |

|

Common applications |

MRI, nuclear magnetic resonance magnets |

Particle accelerators, fusion reactors, high-field magnets |

|

Processing costs and complexity |

Lower cost; high production yield |

Higher cost; lower production yield |

Conclusion

Niobium-Titanium and Niobium-Tin both play significant roles in superconducting technology. Niobium-Titanium is suitable for applications that require formability and a simple manufacturing process. Niobium-Tin offers higher critical magnetic field properties despite necessitating more complex processing. The choice between them depends on specific performance and cost considerations. Advances in superconducting technology depend on matching material properties to application requirements.

Frequently Asked Questions

Q: What is the critical temperature of Niobium-Titanium?

A: Niobium-Titanium has a critical temperature of approximately 9 Kelvin.

Q: Which material is used for high-field magnets in fusion reactors?

A: Niobium-Tin is used because it can withstand magnetic fields up to 30 Tesla.

Q: Why is Niobium-Titanium frequently used in MRI applications?

A: Its ductility and simple manufacturing process make it suitable for MRI magnets.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

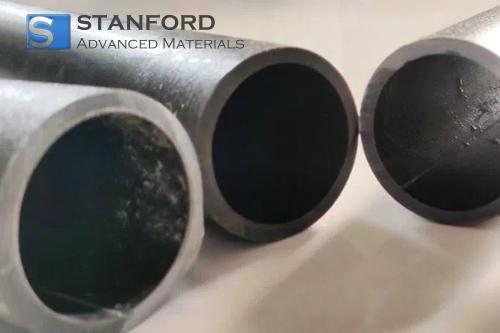

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento