How Porous Silicon Carbide Work For Energy Conversion And Environmental Governance As Catalyst Carriers

1. Introduction

Porous Silicon Carbide has been used for many years in modern catalyst technology. This material exhibits a specific set of properties. Its high specific surface area is an essential factor for effective catalysis, as a larger surface provides more active sites for chemical reactions. Porous Silicon Carbide demonstrates high thermal stability and retains its properties at elevated temperatures. It is chemically inert, meaning that it does not react with many corrosive chemicals. Its substantial mechanical strength enables its use in harsh operating conditions. These characteristics justify its application as a catalyst support.

Modern industry requires catalysts that maintain stable performance over time. In energy conversion and environmental protection, a catalyst that remains stable and effective is critical. Porous Silicon Carbide is preferred for these purposes given that its physical and chemical properties facilitate consistent catalytic performance.

2. Structure of Porous Silicon Carbide

Porous Silicon Carbide displays structural features that are specific to the material. It typically contains pores of varying diameters and a significant proportion of voids. These voids contribute to the overall surface area available for reactions. A high specific surface area is achieved by controlled sintering and chemical vapour deposition, thereby forming a network of pores and channels.

The surface chemistry is critical for the support’s functionality. A treatment of the Silicon Carbide surface is possible, thereby increasing the catalyst’s adsorption onto the support. For example, the introduction of chemical groups may enhance the chemical interaction between the support and the catalyst. Experiments have shown that surface-treated Silicon Carbide yields improved dispersion of catalyst particles. Industrial trials have demonstrated that the reaction rate increases when these treated materials are employed.

The pore structure also aids in the distribution of active species. A uniform pore size leads to even dispersion of catalyst nanoparticles. This prevents agglomeration and thereby improves reaction efficiency. Standard methods, such as treatment with acids or bases, have been used to modify the surface chemistry. Such modifications tailor the porous structure to meet specific reaction requirements.

3. The Role of Porous Silicon Carbide in Catalysis

Silicon Carbide retains its performance under extreme conditions. It is able to withstand both high temperatures and corrosive environments. Catalysts frequently lose activity when exposed to harsh conditions, whereas porous Silicon Carbide offers a stability that many supports do not. Its porous structure facilitates better dispersion of catalyst particles, thereby ensuring that smaller active particles are evenly distributed.

The large pores promote faster mass transfer, thereby allowing reactants to reach active sites more rapidly. In addition, heat transfer is improved, given that a uniform reaction temperature is maintained. Uniform temperatures help to avoid hot spots that may damage the catalyst. Several laboratory and industrial tests have recorded longer catalyst lifespans and increased activity when porous Silicon Carbide is used as a support.

The combination of thermal, chemical and mechanical stability supports a wide range of reactions. Energy conversion and environmental management processes require materials that accommodate rapid temperature fluctuations and corrosive gases. Porous Silicon Carbide has been verified under these conditions. The improved dispersion of the catalyst means that a lower amount of precious metals is required while maintaining efficiency.

4. Applications in Energy Conversion

Porous Silicon Carbide is employed in various energy conversion processes. One significant application is in the Fischer-Tropsch synthesis, where carbon monoxide and hydrogen react to produce liquid fuels. Trials using Silicon Carbide supports have shown improved catalyst performance.

Another application is the production of synthesis gas via methane reforming. In this process, methane is converted into synthesis gas. The thermal stability of porous Silicon Carbide ensures that the reforming catalyst remains active for extended periods. The methanation of carbon monoxide and carbon dioxide is an additional example; in these reactions, small catalyst particles are securely anchored to the Silicon Carbide support, thereby leading to increased conversion rates.

Practical applications have shown that reactors using Silicon Carbide catalyst supports exhibit improved heat management and enhanced energy efficiency. These factors contribute to optimising fuel production and reducing overall energy consumption.

5. Applications in Environmental Catalysis

Porous Silicon Carbide is also significant in the field of environmental catalysis. Many systems employ it to remove pollutants from exhaust gases. Its chemical inertness ensures that no unwanted side reactions occur, thereby preserving efficiency over time. In water treatment, Silicon Carbide supports are used in filters to capture organic compounds and heavy metals from contaminated water.

Air purification systems also benefit from its structure. Fine particulate matter and harmful gases are captured on the expansive surface of the support. Several pilot projects have utilised porous Silicon Carbide in the treatment of industrial emissions. The improved dispersion of the catalyst, resulting from the porous structure, has led to higher reaction rates and cleaner outcomes.

Industrial installations have recorded longer catalyst lifespans when using porous Silicon Carbide. Lower maintenance costs and increased reaction efficiencies are clear advantages. These benefits contribute to reducing environmental impact and improving public health standards.

6. Conclusion

Porous Silicon Carbide provides a combination of properties that are beneficial for catalysis. Its large surface area, thermal stability, chemical inertness and mechanical strength support improved mass and heat transfer during reactions. The material has a measurable impact on energy conversion processes, such as Fischer-Tropsch synthesis, methane reforming and methanation, as well as on environmental catalysis by removing pollutants from water and air. The application of porous Silicon Carbide as a catalyst support promises more efficient and environmentally sound industrial processes.

7. Frequently Asked Questions

F: Why is porous Silicon Carbide ideal for catalysis?

F: Its large surface area, thermal stability, chemical inertness and mechanical strength enhance catalyst dispersion and reaction efficiency.

F: How does the porous structure improve reaction performance?

F: The porous structure facilitates improved mass and heat transfer, thereby ensuring that the catalysts are evenly distributed and remain active.

F: For which applications is porous Silicon Carbide typically used?

F: It is employed in energy conversion, for example in Fischer-Tropsch synthesis and synthesis gas production, as well as in environmental catalysis for pollutant removal.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

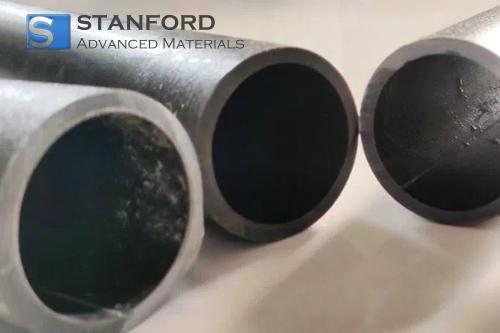

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento