List Of Iridium Materials In The Aerospace Industry

Why the Aerospace Industry Relies on Iridium

Aerospace Applications often require materials that withstand extreme temperatures and harsh chemical environments. Iridium exhibits a high melting point and durability. These properties make it a practical choice for parts exposed to high loads. Aircraft components, space vehicles and satellites benefit from the strength and stability of Iridium.

The following table provides an overview of the principal properties of Iridium:

|

Property |

Value / Description |

|

Atomic number |

77 |

|

Symbol |

Ir |

|

Atomic mass |

192.22 u |

|

Crystal structure |

Face-centred cubic (FCC) |

|

Density |

22.56 g/cm³ |

|

Melting point |

2 446 °C (4 435 °F) |

|

Boiling point |

4 428 °C (8 002 °F) |

|

Electrical resistivity |

~5.3 μΩ-cm at 20 °C |

|

Thermal conductivity |

147 W/m-K |

|

Coefficient of thermal expansion |

6.4 × 10⁻⁶ /K |

|

Hardness |

~6.5 (Mohs scale) |

|

Tensile strength |

200–500 MPa (varies with form and processing) |

|

Corrosion resistance |

High; it withstands acids, oxidation and salts |

|

Magnetic properties |

Paramagnetic |

|

Applications |

Crucibles, spark plugs, aerospace, electrical contacts, medical devices |

Iridium Alloys in High-Performance Aeronautical Systems

In high-performance aerospace systems, iridium alloys are frequently employed. Engineers use these alloys in the design of jet engines, rocket engines, nozzles and re‐entry vehicle components. Studies have shown that iridium alloys withstand rapid temperature fluctuations. Their strength remains consistent under significant mechanical stress. Consequently, these alloys contribute to the safety and operational performance of aerospace systems. In many applications, these alloys are used where failure cannot be tolerated. For example, re‐entry vehicles require materials that resist intense heat and stress.

Iridium Coatings for Extreme Environments

Iridium coatings provide additional protection in adverse environments. Many combustion chambers and engine components receive an iridium coating to resist thermal and chemical damage. The metal is applied as a thin film that shields the base materials.

In practice, iridium coatings reduce oxidation at high temperatures and protect against corrosion from reactive chemicals present in rocket propellants. Given that high temperatures with oxygen exposure cause oxidation in many metals, an iridium coating significantly lowers this risk. This method has been employed in numerous engine components in aerospace, thereby maintaining performance over time.

Iridium in Satellite and Propulsion Technology

In satellites and propulsion systems, iridium plays multiple roles. It is a key component in satellite thrusters and hydrazine catalysts, which are used for propulsion. These catalysts assist in the decomposition of fuel to generate the required thrust. The material is also incorporated in systems designed for stationary operation. This design allows satellites to remain in their designated orbits for extended periods.

The performance of iridium is critical when minor malfunctions could lead to system failure. Many propulsion systems have long operational lifetimes. In these cases, any material that maintains its performance over time is essential. Iridium aids in the stabilisation and maintenance of the control systems that guide spacecraft.

Radiation-Hardened Iridium Components

Space is subject to high levels of radiation. Electronic equipment and other components must be protected against such exposure. Iridium components are used for radiation shielding and in the enclosures of nuclear radioisotope thermoelectric generators (RTGs). RTGs depend on iridium to securely contain their radioactive material.

The chemical stability of iridium ensures that it does not degrade in highly irradiated zones. Furthermore, its high density provides a barrier against high-energy particles. Aerospace engineers have employed iridium in missions where prolonged radiation exposure might otherwise damage critical electronic and structural components.

Iridium Catalysts for Space Propulsion

Catalysis represents another important application for iridium in space. In certain propulsion systems, the metal functions as a catalyst in the decomposition of monopropellant fuels. This process releases energy rapidly and efficiently to generate thrust. Some satellites and interplanetary missions rely on this catalytic process for precise manoeuvres.

This property of iridium ensures that efficient propulsion is achieved even with low fuel consumption. In many cases, satellites exhibit a more stable and responsive operation because the catalytic reaction remains constant over time. The consistent performance of these catalysts provides mission planners with an additional level of assurance.

Conclusion

Iridium plays a critical role in the aerospace sector. The alloys, coatings, catalysts and radiation‐hardened components all contribute to the operational performance and safety of aerospace systems. Whether used in high-performance jet engines or in sensitive satellite thrusters, iridium is a fundamental material. Aerospace engineers have used this metal for many years, and its significance is likely to increase as technologies extend into more extreme environments.

Frequently Asked Questions

Q: Why is iridium used in the aerospace industry?

Q: Iridium withstands high temperatures and aggressive chemicals, which makes it suitable for critical aerospace components.

Q: Where is iridium used in propulsion systems?

Q: Iridium is utilised in catalysts for monopropellant systems and in satellite thrusters for efficient fuel decomposition.

Q: How do iridium coatings benefit engine components?

Q: Iridium coatings provide thermal, oxidation and corrosion resistance, thereby extending the service life of engine components.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

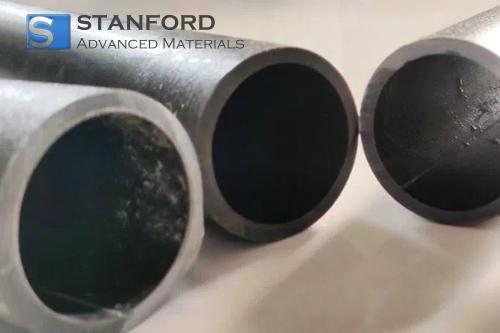

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento