List Of Sputtering Targets In Flat Panel Displays

Description

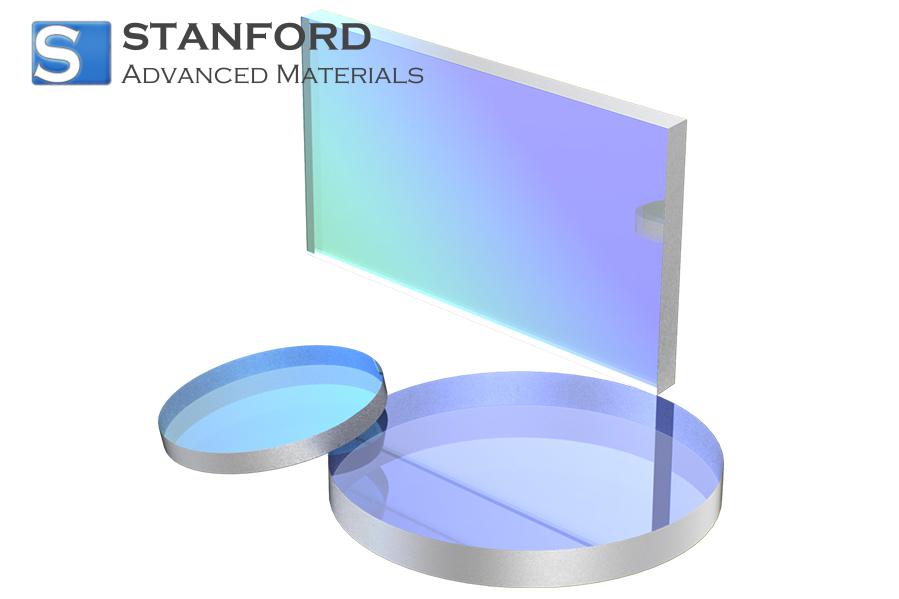

Flat-panel displays rely on thin films produced by a sputtering process. In this process, atoms are ejected from a target material by means of a high-energy ion beam. These atoms are then deposited as a very thin film on a glass substrate. The films may conduct electricity or block light. This dual function supports display operation.

Flat-panel displays include liquid crystal and plasma types. Each display requires films with specific properties. The films may offer transparency, electrical conductivity or act as protective barriers. The sputtering process allows precise control of these film properties.

In the early days of electronics, obtaining uniform films was difficult. Sputtering enables manufacturers to produce films with a thickness of approximately 100 nanometres. These films cause minimal change in light output and exhibit low electrical resistance when required. Sputtering targets are central to this deposition technique.

The process is repeated on large glass panels, thereby creating millions of pixels. Display performance and reliability depend on the uniformity of the film. This method is standard in the manufacture of televisions, computer monitors and mobile displays. Manufacturers select sputtering target materials with particular care.

List of Sputtering Targets in Flat-Panel Displays

Numerous materials serve as sputtering targets. Below is a list of commonly used materials with their properties and applications:

1) Indium Tin Oxide for transparent, conductive films

This target produces a film with a typical resistance of 10 Ohm per square. It offers around 80 per cent light transmittance. Flat-panel displays use this film as a transparent electrode.

2) Aluminium Sputtering Target for reflective electrodes

Aluminium is a lightweight and inexpensive metal. It is easily deposited and forms a conductive film. In displays with reflective properties, aluminium films are combined with other materials.

3) Copper Sputtering Targets for conducting traces

Copper exhibits excellent electrical conductivity. It is used to form conductive paths on a display. Copper films ensure effective signal conduction and reduce energy losses.

4) Molybdenum Sputtering Target for barrier layers

Molybdenum films are used as diffusion barriers. They protect sensitive layers from undesirable interfacial interactions. Given that these films remain stable, they help control chemical reactions during device operation.

5) Tungsten Sputtering Target for high-temperature films

Tungsten is used to obtain films that maintain their properties at elevated temperatures. The films perform well under thermal stress.

6) Titanium Nitride Sputtering Target for protective coatings

Titanium nitride films show high wear and corrosion resistance. They are applied as protective layers in areas where the display may face mechanical forces or chemical exposure.

7) Silver Sputtering Targets for improved reflectivity

Silver provides high electrical conductivity and reflective capability. In some specialised panels, silver films are used to enhance screen brightness.

Conclusion

Flat-panel displays require various sputtering target materials to produce films with defined characteristics. These targets range from conductive transparent layers to protective coatings. The selection of targets directly influences display performance and production consistency. With the appropriate target, the film on a glass substrate fulfils its function as an electrode, barrier or reflector. Material properties and deposition parameters are critical to modern display technology.

Frequently Asked Questions

Q: What is sputtering in flat-panel displays?

A: Sputtering is a process in which atoms are ejected from a target and deposited onto a substrate to form a thin film.

Q: Why is Indium Tin Oxide commonly used?

A: Indium Tin Oxide provides approximately 80 per cent transparency and the electrical conductivity required for display electrodes.

Q: How does the quality of the targets affect flat-panel display production?

A: Targets with consistent composition yield uniform films. This reduces production variability and lowers the incidence of manufacturing defects.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento