MAX Phase Ceramics Explained: Structure, Properties, and Applications

Introduction

Scientists and engineers have been interested in a special group of materials known as MAX Phase Ceramics. These materials bring together the best aspects of ceramics and metals. They are not one-dimensional in their behaviour. Instead, they show both the high-temperature stability of ceramics and the excellent machinability of metals. In simple terms, these compounds behave as ceramics in hardness and metals in their ability to bend. Such a mix makes them useful in numerous applications.

Structure of MAX Phase Ceramics

The phrase “MAX Phase” comes from their chemical formula. In this formula, M stands for a transition metal, A is an element from groups 13 or 14 in the periodic table, and X represents carbon or nitrogen. This combination creates a layered structure that gives the material its unique behaviour.

At the heart of MAX Phase Ceramics is their layered crystal structure. Each layer contributes to what we see as a balance between ceramic and metal qualities. The general formula for these compounds is written with three letters: M, A, and X. For example, in a compound such as Titanium Silicon Carbide (Ti3SiC2), titanium is the transition metal, silicon serves as the A element, and carbon occupies the X spot.

The atomic layers are stacked in a manner that leads to weak bonding between certain layers. This design is what gives these ceramics some of their surprising features. The layers where metallic bonds exist allow the material to absorb impact without breaking easily. Meanwhile, the ceramic layers maintain the material's stability even at high temperatures. The result is a material that can withstand high stress levels and hot conditions while still being easily shaped.

This structure differs significantly from that of traditional ceramics. In common ceramics, a strong ionic or covalent bond holds the atoms in place in a rigid manner. MAX Phase Ceramics have this built-in flexibility due to their unique bonding pattern. This balanced design means the material can be used where traditional ceramics would fracture under physical shock or changes in temperature.

The layered structure also means that cracks do not spread easily. In many cases, a crack might deflect or stop entirely when it encounters a different layer. This quality gives MAX Phase Ceramics an advantage in applications that require a tough yet light material. Many researchers have tested these compounds using methods such as electron microscopy and X-ray diffraction to confirm their structure. Such tests indicate that these ceramics maintain their pattern even after years of use in various environmental conditions.

Key Properties of MAX Phase Ceramics

One of the most intriguing aspects of MAX Phase Ceramics is their unique set of properties. They can endure high heat, resist corrosion, and have a surprising level of ease in machining. Let me delineate a few of these properties with specific examples.

First, consider thermal stability. These ceramics can sustain high temperatures for extended periods. For example, when Titanium Silicon Carbide is heated, it remains stable well above 1 000°C. This is a useful property when working with machines or devices that often operate at high temperatures. The materials do not lose their shape or integrity, even after constant heating.

Next comes the property of electrical and thermal conductivity. Unlike most ceramics, which do not conduct electricity well, MAX Phase Ceramics exhibit metal-like conductivity. This means they can be employed in applications where heat must be dissipated quickly. In one instance, a sample of these ceramics displayed conductivity readings comparable to some pure metals. This property can be critical for designing systems that require rapid heat dissipation.

Another key property is machinability. Traditional ceramics are known to be brittle and hard to shape. MAX Phase Ceramics, however, can often be cut and shaped using conventional tools. This makes them appealing for parts that need to be customised during production. For instance, industries that produce high-performance components frequently use these ceramics because they can be finished to very tight tolerances without requiring highly expensive machinery.

Wear resistance is also a noted quality. These ceramics can endure friction and wear without breaking apart. In practical terms, they have been subjected to speeds and abrasive conditions where normal ceramics would quickly wear out. Specific tests have shown that wear rates are significantly lower in some MAX Phase compounds compared to traditional ceramics. This means that parts made from these materials can have a long lifespan even in harsh settings.

Lastly, these ceramics possess an interesting ability to self-heal minor cracks. Under certain conditions, small cracks may close up naturally under heat or pressure. This contrasts with normal ceramics, which would simply crack and become unusable. The self-healing property, while not spontaneous in every situation, occurs often enough to be considered a considerable benefit.

While the numerical data can vary based on the specific compound and processing method, the overall picture is clear. Many experiments support that these ceramics can handle high temperatures, operate under stress, and be processed into complex shapes. The combination of properties makes MAX Phase Ceramics a valuable material for engineering challenges that require durability and flexibility.

Applications of MAX Phase Ceramics

The practical uses of MAX Phase Ceramics are extensive and varied. They have found roles in industries that require materials with both toughness and high-temperature stability. Let us discuss some common cases and examples that illustrate how and where these ceramics perform best.

One area is the automotive industry. Some car parts experience high friction and heat. Utilising MAX Phase Ceramics in these parts can lead to longer-lasting components. They are used as wear-resistant coatings on engine components. In one trial, a turbine component coated with a MAX Phase compound demonstrated a wear reduction of up to 30 per cent compared to standard coatings.

Another common application is in high-temperature processing equipment. The ceramics can be used in furnaces or heating elements where the material must endure severe heat. Their strong thermal stability renders them ideal for parts that must be both strong and light. For example, certain sections of industrial ovens have been replaced with components made from these ceramics to maintain performance even after long hours of operation.

In the field of electronics, materials combining heat conductivity and physical durability are essential. MAX Phase Ceramics perform well in environments that heat up rapidly. They are efficient in transferring heat away from sensitive components. One known application involved the use of these ceramics in high-power electronic substrates. This assisted in maintaining stable temperatures without overheating in electronic devices.

There are also potential applications in cutting tools. The high durability and self-healing properties make these ceramics suitable for components that experience significant wear. Some research indicates that tools coated with MAX Phase compounds maintain their edge longer than those with standard ceramics. Although not every manufacturer has revised their processes, the initial data appears promising.

Furthermore, these ceramics have begun to find a role in wear-resistant coatings for various industrial equipment. Parts that are subjected to constant friction and stress benefit from the toughness of MAX Phase Ceramics. In several laboratory trials, specimens coated with a MAX Phase compound outperformed uncoated ones in longevity tests.

Conclusion

In summary, the applications of MAX Phase Ceramics are extensive. They are present in automotive components, high-temperature furnaces, electronic devices, and even in cutting tool coatings. The unique combination of ceramic and metallic qualities renders them excellent candidates for any situation that demands strength, heat resistance, and durability in one material. Each application leverages a different aspect of their properties, demonstrating the versatility of these ceramics. For more advanced ceramics, please check Stanford Advanced Materials (SAM).

Frequently Asked Questions

F: What are MAX Phase Ceramics made of?

Q: They consist of a transition metal, an A-group element, and carbon or

nitrogen.

F: Can MAX Phase Ceramics handle high temperatures?

Q: Yes, many compounds remain stable above 1 000°C.

F: Are these ceramics easy to shape compared to traditional

ceramics?

Q: Yes, they can be machined using standard techniques without much difficulty.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

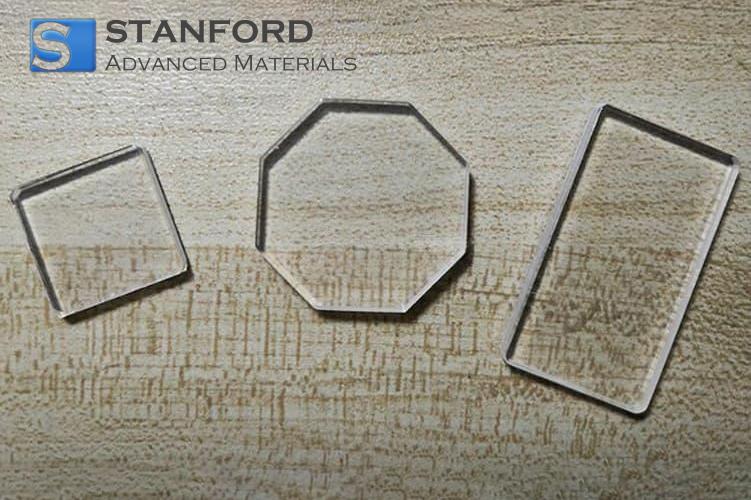

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

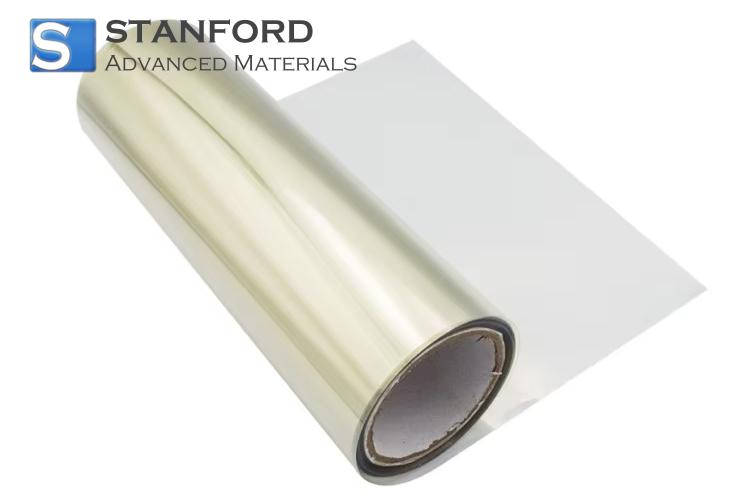

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento