Niobium-Titanium Alloys In High-Performance Capacitors, Optical Coatings, And Conductive Components

Description

Niobium-Titanium alloys are utilised in various devices. They are employed in modern equipment. Their strength and stability render them effective. This article explains how these alloys support high-performance capacitors, improve optical coatings and manufacture stable conductive components.

What are Niobium-Titanium Alloys?

Niobium-Titanium Alloys are mixtures of niobium and titanium. A common composition is approximately 47.5% niobium and 52.5% titanium. They provide a balanced combination of mechanical strength and electrical performance. The alloys perform well under demanding conditions. They exhibit good resistance to wear and withstand high temperatures. They have been employed in high-technology applications for many years. Their consistent performance ensures their use in the design of many devices.

High-Performance Capacitors

Capacitors store electrical charge and manage pulses in circuits. High-performance capacitors require materials that do not degrade rapidly. Niobium-Titanium alloys provide a uniform electrical flow and handle rapid current fluctuations. They are used as electrode materials in certain modern capacitors. In capacitors for aerospace or military systems, niobium-titanium electrodes may be employed, given that they maintain stable performance under load. In many instances, these alloys contribute to maintaining consistent functionality when the frequency exceeds 100 kilohertz. This renders them a suitable choice for the development of modern capacitors.

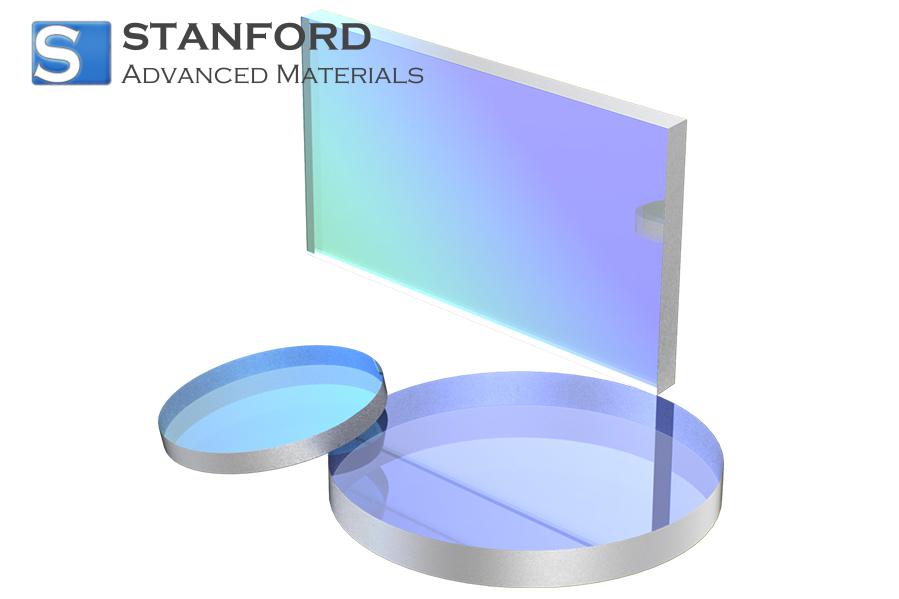

Optical Coatings

Optical coatings control the incidence of light on a surface. They are applied to reduce glare or to increase reflectance. Niobium-Titanium alloys assist in producing such coatings. When deposited as thin films, the alloys form permanent layers on glass or other substrates. Manufacturers utilise these layers in sectors such as photography and astronomy. In some cases, the coating thickness is only a few nanometres. This thin layer leads to measurable improvements in image clarity and protection. The stability of niobium-titanium alloys ensures that the coatings do not wear quickly, even when subjected to varying temperatures and environmental conditions.

Conductive Components

Many devices use materials that conduct electricity while retaining structural integrity. Niobium-Titanium alloys perform well for conductive components. Their excellent conductivity permits their use for wiring in high-frequency circuits. They also operate in systems that function at very low temperatures. Superconducting magnets in medical imaging and particle accelerators rely on these alloys to operate correctly. Their capability to withstand high loads and low temperatures facilitates efficient current conduction. In several designs, the application of niobium-titanium alloys reduces energy loss and improves overall device performance.

Further reading: List of Superconductors and How They Work

Conclusion

Niobium-Titanium alloys play a key role in various high-technology applications. They support the performance of high-capacity capacitors, enhance the quality of optical coatings and ensure consistent conductivity in critical components. Further applications are detailed at Stanford Advanced Materials (SAM).

Frequently Asked Questions

Q: Are Niobium-Titanium alloys effective conductors at low temperatures?

Q: Yes, they maintain their electrical conductivity and mechanical strength in cryogenic environments.

Q: Are these alloys used in aerospace and medical devices?

Q: Yes, they are frequently implemented in systems such as MRI equipment and aircraft circuit boards.

Q: Do Niobium-Titanium alloys resist corrosion and wear?

Q: Yes, their composition provides resistance to corrosion and wear under harsh conditions.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento