SiC And Si₃N₄ Ceramics In Environmental Protection And Clean Energy

Description

Silicon carbide and silicon nitride ceramics are utilised in various industrial sectors. They offer high mechanical strength. Their performance remains stable at high temperatures and in demanding conditions. This article evaluates their role in reducing environmental emissions and supporting clean energy initiatives.

Content

Silicon Carbide (SiC) is a compound composed of silicon and carbon bound together. Silicon nitride, or Si₃N₄, is a ceramic that contains silicon and nitrogen. Both materials maintain performance under high temperatures and pressures.

SiC exhibits high thermal conductivity and has a melting point exceeding 2 700°C. It features a wide bandgap. The material is employed in electronic devices and high-performance engines. In environmental protection, SiC ceramics are used in filtration systems to capture harmful particles. Components manufactured from SiC withstand heat and friction. Consequently, in solar cells, SiC components enhance the conversion of sunlight into clean energy. For instance, many solar cell modules integrate SiC-based parts to improve efficiency under bright sunlight.

Silicon nitride demonstrates high fracture toughness and low thermal expansion. Its structure resists rapid temperature fluctuations without failure. Si₃N₄ ceramics are frequently applied in turbine blades and engine parts. This material is chosen because it maintains functionality under demanding conditions. In clean energy applications, Si₃N₄ is used in gas turbines and engines where high temperatures require components with long service lives. Its strength contributes to the effective operation of clean energy systems, notably in wind turbines and power converters.

Related Cases and Studies

Consider specific cases. A power station replaced its older turbine blades with Si₃N₄ components. Consequently, the station improved operational efficiency and reduced greenhouse gas emissions. In another instance, manufacturers installed SiC filters to remove dust and harmful chemicals from exhaust gases. These filters maintained performance even after extended use, thereby reducing airborne pollutants.

The characteristics of both ceramics contribute to energy-saving techniques. SiC is employed in inverters for electric vehicles and wind turbines. Its performance results in reduced energy loss during conversion. Consequently, energy usage becomes more efficient and CO₂ emissions decrease. Si₃N₄ underwent testing under extreme generation conditions and maintained its strength after thousands of hours at temperatures over 1 300°C. This wear resistance makes it a common choice.

When installations experience wear under harsh conditions, maintenance costs increase. Both SiC and Si₃N₄ ceramics demonstrate long-term stability and resist corrosive gases and high temperatures. Consequently, significant cost savings are achieved. This efficiency improvement directly supports cleaner energy production and reduces the frequency of component replacement.

The clean energy sector now focuses on sustainability and minimal environmental impact. Materials that fulfil these objectives are critical. SiC and Si₃N₄ ceramics contribute to the safe operation of energy installations and industrial units. Their extended service lives and consistent performance support machinery that operates efficiently. They provide a dependable method for reducing maintenance downtime and resource consumption.

Researchers and engineers select these ceramics because they perform well under demanding conditions. They have been implemented in various projects that aim to reduce environmental pollutants and data volumes. Numerous studies provide numerical data. For example, research indicates that SiC filters capture over 95% of harmful particles in combustion systems. Data reveal that Si₃N₄ maintains its strength after thousands of hours at temperatures over 1 300°C. These figures support initiatives in environmental safety.

Both materials have been utilised in heavy industry for many years. Over time, technological advances have aligned these ceramics with modern clean energy requirements. They are used in new power stations, power converters and pollution control devices. Adjustments in design and manufacturing methods have increased their effectiveness, without compromising safety or lifespan.

Conclusion

SiC and Si₃N₄ ceramics are significant in environmental protection and clean energy. Their performance and durability have contributed to reducing harmful emissions and energy wastage. They are suitable for filters, engine components and power conversion devices. Their ability to withstand high temperatures and wear supports reliable operation. Their incorporation in modern systems demonstrates the continued relevance of traditional materials in addressing energy challenges. Engineers and companies utilise this durability to reduce maintenance and repair costs. These ceramics remain an integral part of sustainable clean energy technology.

Frequently Asked Questions

Q: What is the primary use of silicon carbide in clean energy technology?

Q: It is used in high-performance inverters and filters in solar cells and electric vehicles.

Q: How does silicon nitride perform in harsh environments?

Q: It resists thermal shocks and mechanical stresses and is applied in turbines and engine components.

Q: Can these ceramics improve energy efficiency in industrial installations?

Q: Yes, their extended service life and stable performance reduce waste and enhance overall efficiency.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

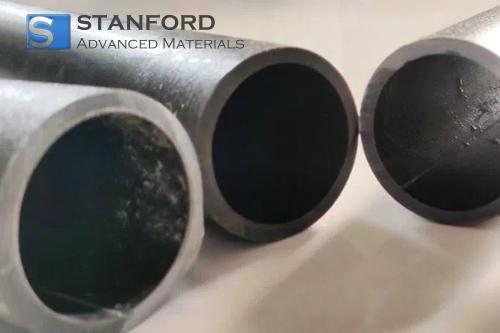

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento