Types Of Corrosion-Resistant Bearings For Clean Technologies

Description

Corrosion resistant bearings play a key role in sustainable technology. They withstand aggressive chemicals and varied environmental conditions. Many clean technologies depend on these bearings to maintain operational continuity. Examples include wind turbines, solar tracking systems and water treatment facilities. This article provides an overview of different types of rolling bearings, examines their characteristics and presents examples from practical applications.

Content

Corrosion in bearings is a common issue in industries that handle chemicals, saltwater or urban pollutants. Engineers and technicians have investigated methods that improve bearing performance. Long-term studies and practical experience have resulted in the development of various types of corrosion resistant bearings.

Stainless Steel Bearings

One prevalent type is stainless steel bearings. These bearings are produced using high-quality metals, such as grade 316 stainless steel. Grade 316 is preferred because it contains molybdenum, which increases resistance to chloride corrosion. In coastal areas, stainless steel bearings have performed reliably. Many wind turbine manufacturers use them to ensure the longevity of their installations. Reports indicate that, when properly maintained, stainless steel bearings can operate for up to 20 years.

Ceramic Bearings

Another recognised category is ceramic bearings. Ceramic materials provide marked resistance to corrosion and contribute to low friction. They withstand high temperatures and exposure to aggressive chemicals. Ceramic bearings are employed in applications where even small particles can cause malfunctions. In solar tracking systems, for example, ceramic bearings promote consistent movement. They are also employed in high-speed applications, thereby increasing operating efficiency. In certain cases, ceramic bearings have maintained performance even under continuous chemical cleaning.

Hybrid Bearings

Hybrid bearings combine ceramic and steel components. The cage and race are generally made from steel while the rolling elements are ceramic. This design allows for high load capacity with reduced friction. Hybrid bearings are installed in precision equipment in water treatment plants and chemical processing facilities. One instance involved a municipal water treatment plant that experienced reduced maintenance downtime following the installation of hybrid bearings.

Polymer-based Bearings

A less common yet promising alternative is polymer bearings. These bearings utilise materials such as Polytetrafluoroethylene (PTFE) and other technical polymers. They do not offer the same mechanical strength as metal bearings but feature resistant surfaces. They are self-lubricating and reduce friction and wear. They are suitable for use in highly chemical environments. Polymer-based bearings are generally selected for lower load applications compared with hybrid or metal bearings.

Related Cases

Practical data underline the importance of material selection. In one instance, a solar power station in Nevada replaced conventional steel bearings with hybrid bearings. This change resulted in a reduction in operating temperature and a decreased frequency of maintenance. In another example, the introduction of ceramic bearings in a chemical processing facility in Texas reduced bearing-related downtime. These cases indicate that bearing choice should reflect environmental conditions and load factors.

Conclusion

In conclusion, corrosion resistant bearings are vital for the operation of clean technologies. Stainless steel bearings, ceramic bearings, hybrid bearings and polymer-based bearings all offer specific attributes and are suited to different applications. Choosing a bearing based on verified data and previous case studies can result in a longer service life and reduced maintenance requirements. As technology advances, these bearings will assume an increasingly significant role in sustainable and secure industrial processes.

Frequently Asked Questions

Q: Why are stainless steel bearings well suited for coastal regions?

Q: They are selected because the inclusion of molybdenum increases resistance to chloride corrosion, thereby extending their service life.

Q: What benefits do ceramic bearings offer in high-speed applications?

Q: They provide low friction and maintain performance at high temperatures and in the presence of aggressive chemicals.

Q: Are hybrid bearings used in water treatment plants?

Q: Yes, they are preferred in chemically intensive environments because of their precision and long-term durability.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

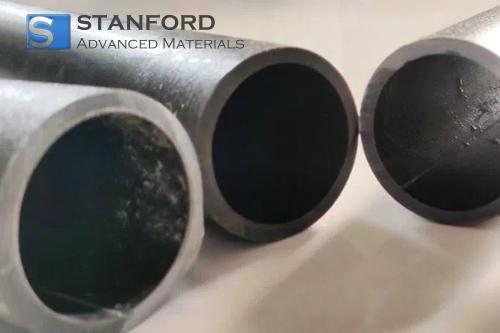

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento