The Past And Preset Of Molybdenum: Discovery And Applications

Molybdenum is a silvery‐white, hard and tough metal with a high melting point and high thermal conductivity. Owing to its high strength, high melting point, excellent corrosion resistance and high wear resistance, it is used in the steel industry, petroleum industry, chemical industry, electrical and electronics sectors, medical field and agriculture. In this article, we examine the discovery, properties and applications of Molybdenum.

Discovery, properties and applications of Molybdenum

The Discovery of Molybdenum

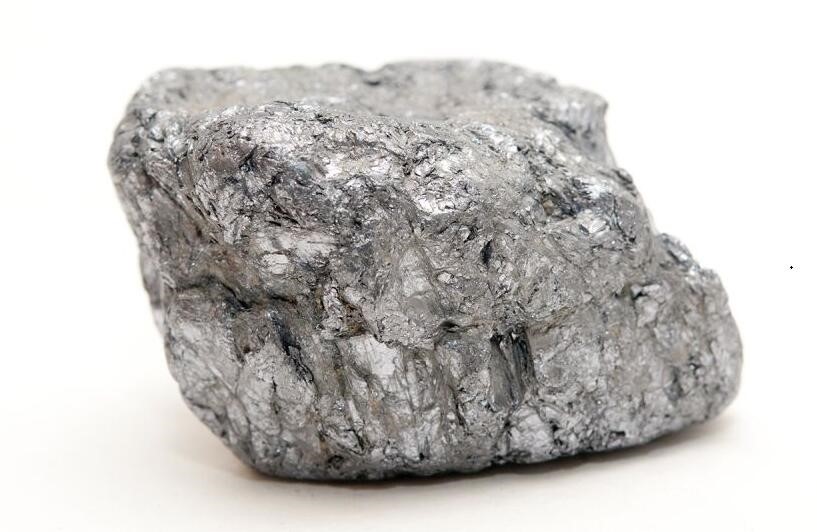

Molybdenum is a hard, silvery‐white metal. How was Molybdenum discovered?

The soft, black mineral molybdenite (molybdenum sulphide) was frequently mistaken for graphite or lead ore until 1778 when the German chemist Carl Scheele analysed it and confirmed it was neither of these substances nor an entirely new element. Given that Scheele did not have a suitable furnace to reduce the white solid to metal, the identification took several years.

Scheele later became known as "Scheele the Unfortunate" as several of his chemical discoveries, including oxygen, were credited to others. In subsequent years, researchers assumed that molybdenite contained a new element; however, it proved difficult to identify because no one managed to reduce it to the metal. Some researchers converted it into an oxide which, in the presence of water, formed molybdic acid, but the metal itself remained undetected.

Eventually, the Swedish chemist Peter Jacob Hjelm ground molybdic acid with carbon in linseed oil to create a paste. This paste ensured close contact between the carbon and the molybdenite. He then heated the mixture in a sealed crucible to produce the metal, which he named Molybdenum after the Greek word "molybdos", meaning lead. According to the Royal Society of Chemistry, the new element was announced in the autumn of 1781.

Development of the Molybdenum Industry

In 1891 the Frenchman Snyder Schneider introduced lead as an alloying element to produce molybdenum armoured plates. He verified that molybdenum performed better than tungsten. Consequently, molybdenum gradually replaced tungsten and was employed as an alloying element in steel, marking the commencement of industrial applications for molybdenum.

In 1900, the ferromolybdenum production process was established, enabling molybdenum steel to meet the specific performance requirements of armour steel. By 1910, production of molybdenum steel increased substantially. Since then, molybdenum has become an essential component in heat‐resistant and corrosion‐resistant construction steels and has gained significance in non‐ferrous nickel alloys and chromium alloys.

Molybdenum is widely used in the electrical industry. One reason is that powder metallurgy and pressing techniques for this dense metal have been rigorously researched and implemented in production. Another reason is that the First World War led to an increased demand for tungsten. Given the supply shortages of tungsten, molybdenum, with its high hardness and impact toughness, was used as a substitute. With growing demand, new molybdenum sources were explored, and a large Clay-Max molybdenum deposit was discovered in Colorado, USA, which was mined from 1918.

To address the decrease in demand for molybdenum after the First World War, researchers investigated its use in civilian industries, such as incorporating molybdenum into steels for wheel manufacturing. In 1930, researchers proposed that forged and heat‐treated molybdenum‐based high‐speed steels satisfy stringent standards. This finding opened a new application market for molybdenum. Consequently, the incorporation of alloying elements initiated a new phase in the use of molybdenum in steel and other materials.

By the late 1930s, molybdenum was a widely used industrial raw material. During the Second World War, the American molybdenum company Clay Max developed a vacuum arc melting process that produced molybdenum ingots weighing between 450 and 1 000 kilograms. This process paved the way for utilising molybdenum as a construction material.

Applications of Molybdenum in Modern Industry

Molybdenum is chiefly used in the steel industry (80%), followed by applications in the chemical industry (approximately 10%). In addition, molybdenum is utilised in the electrical industry, the medical field, agriculture and other sectors.

- Steel Industry

In the steel industry, molybdenum is primarily employed in the manufacture of alloyed steel, stainless steel, tool steel, high‐speed steel, cast iron and rolled steel. The incorporation of molybdenum increases strength, toughness, corrosion resistance and wear resistance and improves hardenability, weldability and heat resistance. The production of molybdenum alloys by adding elements such as Molybdenum Lanthanum Alloy and TZM Alloy has demonstrated improved performance relative to pure molybdenum.

- Chemical Industry

In the chemical industry, molybdenum is employed as a lubricant, catalyst, pigment, flame retardant, smoke suppressant and corrosion inhibitor for organic polymers. Principal products include molybdenum dioxide, molybdenum trioxide, molybdate and ammonium paramolybdate.

- Electrical & Electronics Industry

Molybdenum exhibits good electrical conductivity and high temperature resistance. Its coefficient of thermal expansion is comparable to that of glass. It is used in the production of core wire, lead wire, hooks and other components for filament windings. Molybdenum wire is also an appropriate electrode for cutting tool machines that process various steels and hard metals. Its stable processing improves the precision of formed components.

- Medical Sector

Molybdenum is an important nutrient. Along with iron and magnesium, it is an essential trace element. It is present in soil and is absorbed through the consumption of plants and animals that feed on these plants.

After ingestion, molybdenum is absorbed from the stomach and intestines into the bloodstream and then transported to the liver, kidneys and other parts of the body. A portion is stored in the liver and kidneys, while the majority is converted into a molybdenum cofactor. Excess molybdenum is excreted in the urine. The molybdenum cofactor activates four vital enzymes that regulate chemical reactions within the body.

- Animal Husbandry and Agriculture

In animals, molybdenum forms part of an enzymatic composition. The addition of molybdenum supplements to feed meets the nutritional requirements of the animals. Furthermore, molybdenum is one of the essential trace elements for plant growth. The application of ammonium molybdate can substantially increase crop yields.

Conclusion

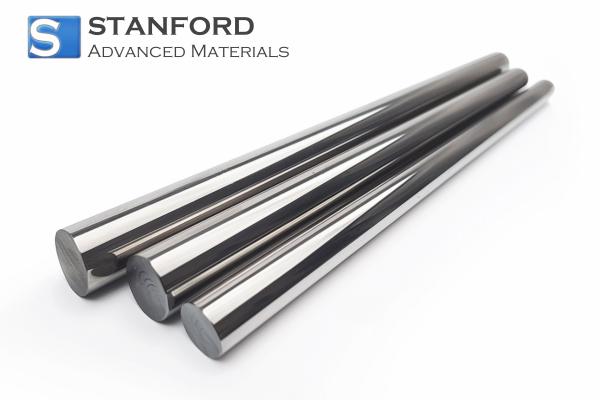

We thank you for reading our article and trust it has enhanced your understanding of the discovery, properties and applications of molybdenum. If you wish to learn more about molybdenum and its alloys, we recommend visiting Stanford Advanced Materials (SAM) for further information.

As a supplier with more than two decades of experience in the manufacture and sale of molybdenum tubes, molybdenum metal powder and molybdenum alloys, Stanford Advanced Materials (SAM) is well established in the production of molybdenum products for research and industrial requirements. We believe that SAM will be your preferred supplier and business partner for molybdenum products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento