Application Of Titanium Dioxide In Sunscreen Products

Ultraviolet radiation consists of light waves that are harmful to the human body. Excessive exposure causes skin redness, heat discomfort, premature ageing and loss of firmness, thereby increasing the risk of skin cancer. Given rising public awareness of these effects, research and production of sunscreens have increased both domestically and internationally. This article examines the use of Titanium Dioxide in sunscreen products.

Titanium Dioxide in Sunscreen Products

Historically, sunscreens mostly utilised organic compounds such as Benzophenones, Salicylates, p-Aminobenzoic Acid and Cinnamic Acids. However, these compounds are unstable and may cause toxicity and irritation. Excessive use may result in chemical allergies and elevate the risk of skin cancer. Nano-Titanium Dioxide has been increasingly adopted as a mainstream sunscreen agent.

Nano-Titanium Dioxide is an inorganic component. It offers chemical stability and thermal stability and provides decolourisation and coverage. It disperses easily and is non-toxic, odourless and non-irritant. The component is safe for use and performs sterilisation and deodorisation.

Ultraviolet light is categorised by wavelength into short-wave, medium-wave and long-wave bands. Short-wave ultraviolet rays possess the highest energy but are blocked by the ozone layer. Consequently, medium and long-wave ultraviolet rays are generally harmful to human health.

Due to its small particle size and high activity, Nano-Titanium Dioxide absorbs, emits and scatters ultraviolet radiation. This effect enables it to block medium and long-wave ultraviolet rays effectively.

Furthermore, the final product demonstrates high transparency due to the fine Nano-Titanium Dioxide particles. Consequently, cosmetic formulators widely prefer Nano-Titanium Dioxide and have gradually replaced some organic ultraviolet protectants. The product development record indicates market potential.

Conclusion

We thank you for reading this article. We hope it improves your understanding of the application of Titanium Dioxide in sunscreen products.

If you require further information regarding Titanium and Titanium Dioxide, please consult Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of Titanium Dioxide. It has over 20 years of experience in manufacturing and distributing Titanium and Titanium Dioxide. It supplies titanium products that meet the research and production requirements of its customers. We believe SAM will be your supplier and business partner for titanium products.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

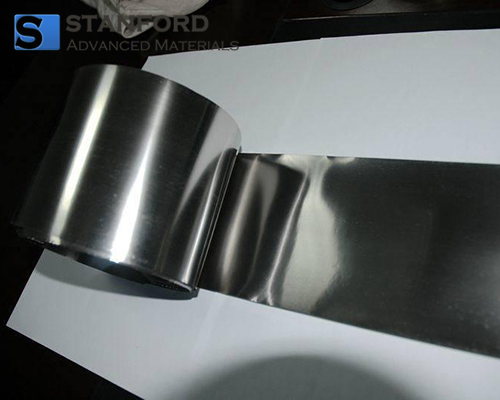

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento