Aviation Aluminum Alloy: New Materials, New Equipment

Aluminium, Magnesium, Titanium and other low-density metals are commonly classified as light metals. Their corresponding Aluminium-, Magnesium- and Titanium alloys are under systematic investigation in research institutions. Their distinct properties and quantifiable development potential have prompted increased attention from academia and industry.

What is Aviation Aluminium Alloy?

Aviation aluminium alloy is a high-strength material widely employed in the aerospace industry. This alloy meets higher requirements in strength, hardness, toughness, fatigue resistance and plasticity than common aluminium alloys. It exhibits favourable mechanical and processing properties and maintains high strength with adequate toughness at 150 ℃ or above, making it a viable candidate for aerospace structural materials.

The principal attribute of aviation aluminium alloys is that their strength is enhanced through deformation heat treatment. This process integrates plastic deformation strengthening with phase transition hardening during heat treatment, thereby standardising the forming process and properties. During plastic deformation, the density of crystal defects increases, which induces variation in the microstructure. Processes including dynamic recovery, dynamic recrystallisation, subdynamic recrystallisation, static recrystallisation and static recovery occur. Consequently, well-controlled microstructural changes result in improved mechanical properties and extended service life.

Classification of Aluminium Alloys for Aerospace

Several classification methods exist for aluminium alloys. They are divided into forging and casting alloys. Forging aluminium alloys withstand compressive forces and can be processed into different shapes and specifications, primarily for aerospace equipment manufacturing.

Forging aluminium alloys are further divided into non-heat-treated and heat-treatable types. The non-heat-treated variants rely on cold working for improvement. They include high-purity aluminium, industrial high-purity aluminium, industrial pure aluminium and other specified grades. In contrast, heat-treatable alloys benefit from quenching and ageing to enhance mechanical properties. These can be categorised into hardened aluminium, forged aluminium, ultra-hard aluminium and specialised aluminium alloys.

Application of Aviation Aluminium Alloys

Experimental data indicate that reducing the weight of a vehicle by 1 kg decreases launch costs by approximately 20 000 $. A weight reduction of 15% in a combat aircraft results in a 15% shorter flight duration, a 20% increase in range and a 30% increase in payload capacity. These quantitative improvements underline the importance of lightweight materials in aerospace engineering.

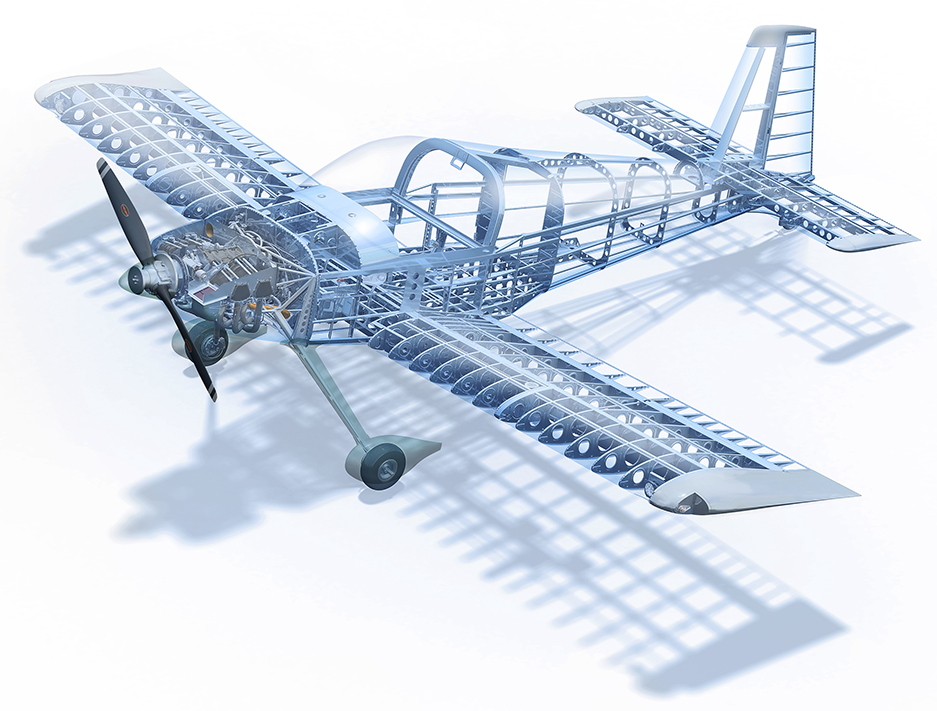

Aviation aluminium alloys are widely used in both aeronautical and astronautical applications. They are selected for attributes such as low density, moderate strength, ease of processing and forming, high corrosion resistance, abundant resource availability and good recyclability. The external skin, beams, ribs, stringers, spacers and landing gears of aircraft are manufactured from these alloys, with usage volumes varying according to aircraft design. Aluminium alloys are common in civil aviation due to economic factors. For instance, aluminium alloy comprises approximately 81% of the fuselage weight in the Boeing 767. Some alloys exhibit advantageous cryogenic properties and are employed in environments containing liquid hydrogen and oxygen. Consequently, the fuel tanks, oxidiser tanks, inter-tank sections, interstage sections, aft sections and instrument capsules of the Saturn V launcher have been fabricated from aviation aluminium alloys.

At present, civil aviation frequently utilises cast parts, forged parts, large extruded profiles, thick plates and Aluminium-Lithium alloys. The primary applications of some key types of aluminium alloys are as follows. 2024 Aviation Aluminium is used in aircraft structural components; 2048 Aviation Aluminium Alloy is principally used for aerospace structural parts and armoured components; 2218 is applied in aircraft engines, diesel engine pistons, engine cylinder heads, turbojet engine impellers and compressor rings; 2219 is utilised for aerospace rocket welding oxidiser tanks, supersonic aircraft skins and other structural parts.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento