Benefits Of Titanium Nitride Coating For Cutting Tools

With the advancement of modern industry, science and technology, materials for cutting tools have been developed considerably. These materials include carbon tool steel, high‑speed tool steel, cemented carbide and composite materials. Many cutting tools currently in use exhibit a short lifespan, which reduces production efficiency because the surface hardness and wear resistance are insufficient.

It was determined that coating the surfaces of tools made from high‑speed steel or hard-alloy steel with a titanium nitride coating improves performance. This article details the benefits of titanium nitride coating for cutting tools.

Benefits of Titanium Nitride Coating for Cutting Tools

Titanium nitride is a stable compound that demonstrates corrosion and oxidation resistance. It has a gold-like appearance; however, its use is primarily functional rather than decorative.

The hardness value of the titanium nitride coating exceeds 2 500 Vickers hardness (HV). When a tool is coated with a titanium nitride layer of 3–5 microns, it exhibits increased wear resistance and heat tolerance. Consequently, the tool’s lifespan and cutting performance improve. For example, the lifespan of a titanium nitride coated roller end mill increases by a factor of 3 to 4. This increase allows for a higher cutting speed when machining gears, thereby reducing processing time and costs.

Physical vapour deposition (PVD) is the method used for applying the titanium nitride coating. In this process, titanium is evaporated under vacuum and reacts with nitrogen to form a hard composite film on the tool surface. The processing temperature is maintained at approximately 350 °C, thereby ensuring that the properties and dimensions of high‑speed steel tools remain unaffected.

Due to its measured performance, titanium nitride coated tools became widely adopted in industrialised countries and have provided significant economic benefits for the machining sector. Japan is a leading nation in this technology. Many Japanese tool manufacturers supply products with a titanium nitride coating. Some products are sold in European countries and the United States, and many have been successfully introduced to the domestic market in Japan.

Conclusion

Thank you for reading this article. We trust that it has assisted in clarifying the benefits of titanium nitride coating for cutting tools. If you require further information on titanium nitride, please visit Stanford Advanced Materials (SAM) for additional details.

Stanford Advanced Materials (SAM) is a global supplier of titanium products and has over two decades of experience in the production and distribution of titanium and titanium nitride. The company supplies titanium products that meet rigorous research and production specifications. Consequently, SAM is a potential supplier and business partner for titanium nitride.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

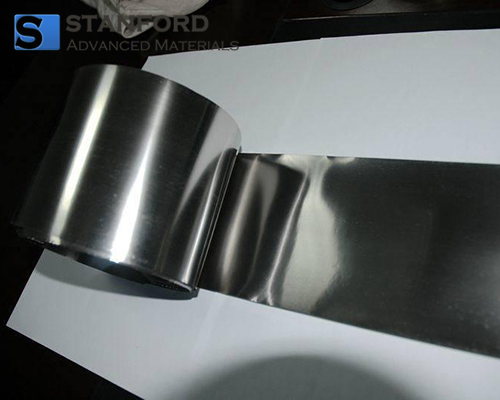

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento