How New Tungsten Carbide Coating Strengthen The Aircraft Parts?

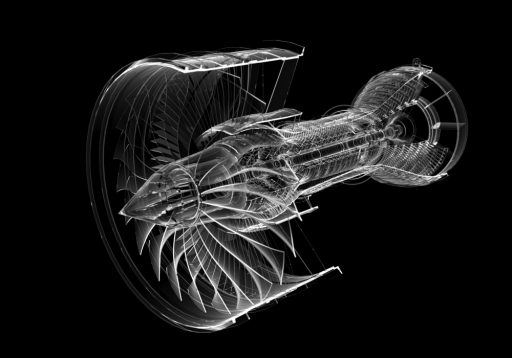

Tungsten Carbide is Widely Used for Aircraft Parts

Tungsten Carbide Materials that possess high hardness, abrasion resistance, high temperature resistance and corrosion resistance are used in aerospace, the oil industry, metallurgy, mechanical engineering and other sectors. In industrial practice, these are identified as cemented carbide coatings. They are produced by utilising Tungsten Carbide/Cobalt as the raw material for thermal spraying onto nickel-based or iron-based substrates. The cost of executing this process is not low; consequently, any reduction in the cost of replacing an entire component is economically justified. The surface finishing coating is widely used in aerospace research and development. Tungsten carbide remains an important coating material for aircraft parts.

New Technologies for Tungsten Carbide Coatings

Due to rapid developments in advanced technology, various performance requirements are placed on materials. Existing coating methods include supersonic flame spraying of tungsten carbide, hard chrome plating, physical vapour deposition of tungsten carbide and explosive spraying of tungsten carbide. Although these techniques have achieved success in certain sectors, each method exhibits specific limitations.

A coating technology known as chemical vapour deposition (CVD) is widely used by established aircraft manufacturers in Europe and the United States. This process deposits tungsten carbide coatings and is recognised as a practical technical and commercial solution. It extends the service life of aircraft components and is applied in the jet engines of aircraft such as the Typhoon and F16.

The CVD coating technology is employed because cobalt is required in conventional spraying methods for cemented carbides. As a binder phase in tungsten carbide materials, cobalt improves the compactness of the material; however, it reduces both wear resistance and corrosion resistance. CVD can be implemented without the use of cobalt. It belongs to the category of nanostructured tungsten carbide coatings and utilises a low-pressure gas medium that crystallises atom by atom. Consequently, by constructing a dense protective layer composed of tungsten and tungsten carbide components that interconnect, both the internal surfaces and the complex geometries of aircraft components are uniformly coated without voids. This method is particularly suitable for designs with intricate shapes that conventional spraying techniques cannot accommodate.

Typical applications of CVD coatings include fuel dosing valves in aircraft, rear thrusters, pins, bushes, bearings, hooks, fasteners, landing gear components, flap tracks and metal strips.

Another advantage of CVD tungsten carbide coatings is that they do not exhibit wear on seals, bearings and other non-metal parts. Uniform nanostructures ensure that the coating wears evenly and maintains or improves surface quality when exposed to abrasive or corrosive environments. In hydraulic actuators, rotating shafts and bearings, a well-coated surface reduces wear on elastomer and PTFE seals and prevents oil leakage.

In summary, tungsten carbide coating technology is widely utilised in the aerospace industry. It mitigates wear on aviation equipment and prolongs the service life of components in aircraft.

Conclusion

We thank you for reading this article and hope that it has provided you with a better understanding of tungsten carbide coatings in aircraft components. For further information on tungsten carbide products, please visit Stanford Advanced Materials (SAM).

Stanford Advanced Materials (SAM) is a global supplier of tungsten metals and tungsten compounds with more than two decades of experience in the manufacturing and distribution of tungsten products that meet the research and production requirements of our customers. We are confident that SAM will prove to be your preferred supplier and business partner.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento