How To Deal With The Brittleness Of Ceramic Materials?

As is well known, ceramic materials possess an inherent flaw, namely their brittleness. The brittleness is determined by the chemical bonding and microstructure, and remains an innate property of ceramics. In the following sections, the brittleness of ceramic materials and methods for its improvement are discussed.

Why are ceramic materials brittle?

Ceramic materials are polycrystalline structures composed of ionic or covalent bonds; consequently, no slip systems exist to enable plastic deformation. During manufacture, microscopic defects are inevitably retained on the material surface, which may lead to crack formation. When the material is subjected to external loading, stress is concentrated at the crack tip. In the absence of an alternative mechanism to absorb this external energy, the energy is redirected as new free energy. This new free energy is consumed by the formation of additional surface area as the crack extends, thereby causing a rapid crack propagation that results in brittle fracture.

How can the brittleness of ceramics be improved?

The brittleness of ceramic materials significantly affects the reliability and stability of their properties. Consequently, many researchers in the field of ceramics are investigating ways to reduce brittleness and proposing methods for its improvement. The following section provides a basic compilation of data.

1. Creation of a Weak Interface System in Ceramic Materials

In ceramic materials, since no mechanism exists to absorb external energy, it is feasible to artificially create weak interfacial structures so that the propagation of cracks can absorb external energy through their dissociation without compromising the entire material. Extensive practice over many years has produced several viable solutions.

* Fibre-reinforced Ceramic Matrix Composites

Fibres (or whiskers) are incorporated into the ceramic matrix in a specific manner. The high-strength fibres share the applied load. The weak interface between the fibres (or whiskers) and the ceramic matrix is used to establish an energy absorption system for external stress, thereby reducing brittleness.

For instance, ceramic matrix composites may be used in the LEAP and CMC components for turbine engine casings. The improved engine requires considerably less cooling air than nickel-based superalloys and exhibits a lower specific weight, thereby saving approximately 15% of the fuel previously used.

* Ceramic Composite Materials

When two different materials are joined, differences in thermal expansion coefficients and elastic moduli induce stress at the grain boundaries. Several studies have shown that the strength and toughness of a material increase when nanoscale grains of one substance are present within micrometre-scale grains of another. This phenomenon is referred to as intracrystalline recombination in the nanometre-to-micrometre range. For example, research has demonstrated that the addition of Nano-Silicon Carbide (5%) and Quad-Zirconium Oxide (15%) to an aluminium oxide matrix can achieve a strength of 1 200 MPa, whereas conventional aluminium oxide ceramics typically have a strength of around 300 MPa.

* Self-Hardening Ceramic Material

Although fibres or whiskers are added to the ceramic matrix for reinforcement and toughness, achieving a uniform distribution in a granular ceramic matrix with a high aspect ratio is challenging. Consequently, the composite properties exhibit variability. It is therefore assumed that if a structure with a specific aspect ratio can be formed within the ceramic matrix, a similar effect to that of fibre or whisker reinforcement may be obtained. A portion of the ceramic body can be processed to form a defined aspect ratio. For example, during the sintering of aluminium oxide ceramics, the addition of a small amount of liquid phase can induce anisotropic grain growth. Consequently, the formation of numerous rod-like crystals with a high aspect ratio in the aluminium oxide matrix substantially improves the strength and toughness.

* Laminated Composite Materials

The concept of laminated composites is inspired by natural microstructures observed in molluscs. Two materials with different components are stacked alternately to form a multilayer laminated composite with parallel interfaces. The design incorporates many weak interfaces that are perpendicular to the direction of applied stress. These weak interfaces alter the primary path of crack propagation and are a significant factor in enhancing material toughness. Given that the materials on either side of the layer possess differing elastic moduli and thermal expansion coefficients, residual stresses are generated.

2. Pre-Stressed Ceramic Material from Zirconium Dioxide

Since the concept of ceramic steel emerged, research into tough ceramic materials based on zirconium dioxide has advanced significantly. Zirconium dioxide compounds exist in three crystal forms: cubic at high temperatures, tetragonal at intermediate temperatures, and monoclinic at room temperature. The tetragonal form can be maintained at room temperature if no external load is applied. When external force is applied, a phase transformation occurs in the metastable tetragonal zirconia. During the phase transformation, a portion of the external energy is absorbed. Moreover, the transformation involves a volume change of between 3 and 5 per cent. Consequently, micro-cracks are generated around the crack tip, which is indicative of an increase in material toughness.

The phase transition in zirconium dioxide contributes to enhanced strength and toughness. This characteristic renders zirconium dioxide an effective additive for the reinforcement and toughening of ceramic materials. A range of zirconium dioxide toughened ceramics has been developed. The tetragonal zirconium dioxide polycrystal (TZP) is a notably important toughened ceramic, demonstrating excellent mechanical properties at room temperature.

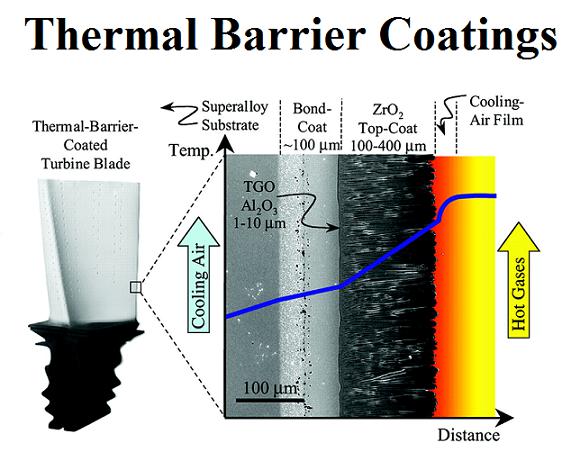

3. Functionally Graded Material

In ceramic coatings, it is often necessary to vary the composition across the coating to secure good performance and high adhesion, either to produce a thicker coating or to reconcile the significant differences in thermal and mechanical properties between the metal substrate and the ceramic coating.

4. Nano-Ceramic Material

A direct correlation exists between grain size and material properties on a microstructural level. When the grain size of a ceramic material reaches the nanoscale, its performance is notably improved. For example, partially stabilised zirconium dioxide ceramics are produced from a mixed powder containing 3 mol% Yttrium Oxide and zirconium dioxide by atmospheric sintering, with gadolinium oxide dispersed in zirconium dioxide as fine crystals with an average diameter of 0.3 μm. When heated above 1 200 ℃, the zirconium dioxide ceramic is capable of an elongation of 12% at a specified strain rate.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento