Introduction Of 4 Ultra-precision Machining Techniques For Si3N4 Balls

Siliziumnitrid-Keramikkugeln (Si3N4) possess many quantifiable properties. They exhibit high hardness, wear resistance, low density, and a low coefficient of thermal expansion. They also offer high heat resistance, non-magnetism, corrosion resistance, high thermal conductivity, self-lubrication and the capacity to endure temperature cycling. These attributes make them the chosen material for ball bearings operating at high temperatures, high speeds and in specialised environments.

Silicon nitride ceramic balls are deployed in wind turbines, high-speed precision spindles, high-temperature engines and other applications. As a key component of bearing systems in essential equipment, the ultra-precision grinding and polishing quality influences bearing performance and service life. The ultra-precision grinding and polishing techniques for Si3N4 ceramic balls are described below.

The ultra-precision grinding and polishing technology for Si3N4 ceramic balls mainly comprises magnetohydrodynamic polishing, chemical-mechanical polishing and ultrasonic-assisted polishing. These processing techniques enable micromachining of the Si3N4 surface. Excess material is removed by controlled plastic fracture. Consequently, a very smooth and undamaged surface is obtained.

Magnetohydrodynamic Polishing

In magnetohydrodynamic polishing, colloidal Fe3O4 is added to an abrasive mixture at a volume fraction of 5–10%. A Si3N4 ceramic ball blank is placed into a cylindrical grinding disc filled with a mixture of magnetic fluid and abrasive. Beneath the disc, a series of permanent magnetic poles are arranged. Under the magnetic field, the magnetic particles move towards the strong field and thereby cause the abrasive to float in the magnetic fluid. When the drive shaft rotates, the ball blank rotates in the mixture while orbiting the disc. The abrasive in the magnetic fluid polishes the ceramic ball. The ball blank undergoes a load of approximately 1 N per ball and exhibits elasticity. Consequently, surface scratches and microcracks from mechanical grinding are markedly reduced.

The material removal rate during magnetohydrodynamic polishing can reach 12 µm/min, which is more than 40 times that achieved by magnetic fluid polishing. Experiments have confirmed that sphericity reaches 0.14 µm and surface roughness is reduced to 0.01 µm after 3 hours of processing.

Chemical-mechanical Polishing

Chemical-mechanical polishing has been applied in ultra-precision processing of technical ceramics, functional ceramics such as yttrium oxide-stabilised zirconium dioxide and metallic materials. During polishing, nano-scale abrasive particles suspended in the liquid cause high temperature and pressure at the contact point with the Si3N4 ball. A chemical reaction occurs rapidly and produces a new material that is softer than the workpiece material. The reaction product is subsequently removed by mechanical friction between the Si3N4 ball and the grinding disc at a scale of around 0.1 nm. Consequently, a super-smooth surface is achieved.

Researchers currently use a cerium oxide polishing solution based on water to chemically and mechanically polish silicon nitride ceramic balls. This process produces a smooth surface with a roughness Ra of 4 nm.

Ultrasonic-assisted Vibrational Polishing

Ultrasonic-assisted vibrational polishing combines ultrasonic vibrations with mechanical processing. Some researchers enhanced the ultrasonic torsional vibration on the upper grinding disc. Consequently, the processing rate increased by two to three times compared with the traditional coarse grinding phase. Researchers also combined magnetorheological polishing with ultrasonic technology to process Si3N4 ceramic balls. Tests indicated that the material removal rate was higher when ultrasonic vibrations were applied. Moreover, the surface roughness of the Si3N4 ball decreased from 0.260 µm to 0.025 µm after 1 hour of processing.

Magnetorheological Cluster Polishing

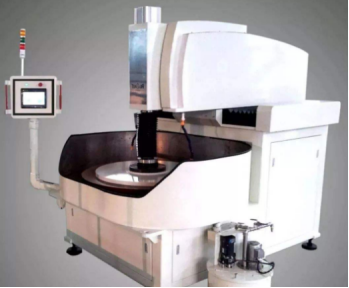

To achieve efficient processing of high-precision ceramic balls, a research team proposed a magnetorheological polishing technique. This method places several small magnetic objects in a regular pattern on the back of both the upper and lower polishing discs made from non-magnetic materials. When magnetorheological polishing fluid is injected onto the disc, a polishing cushion is formed above each magnetic pole. The polishing cushion covers and polishes the ceramic ball. A gap is maintained between the upper and lower polishing discs during processing. During operation, the rigid contact is converted into flexible contact. Given that the polishing cushion continuously covers the ceramic balls, secondary deformation due to impact and heating is reduced. The team developed a test apparatus for magnetorheological polishing of ceramic balls and conducted trials with silicon nitride ceramic balls.

Magnetorheological cluster polishing provides effective polishing, high efficiency and surface protection. This technique improves the polishing efficiency of Si3N4 ceramic balls and guarantees surface quality and form accuracy.

About the Author

Cathie Montanez is the project scientist at Stanford Advanced Materials (SAM). She was previously a research professor at the School of Materials Science and Engineering at a university. She is now responsible for performance evaluation and technical consultation regarding SAM products such as refractory metals, ceramics, laboratory crucibles and abrasive rods.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento