Manufacturing Technology And Application Of Beryllium Foil

Beryllium exhibits a low density, high strength, a high modulus of elasticity, high X‑ray transmittance and a rapid speed of sound propagation. It is used as an analytical instrument in the aerospace sector, in large‑scale integrated circuit (LSI) fabrication and as a component in audio systems. In this article we review the manufacturing technology and applications of Beryllium foil.

Manufacturing Technology and Application of Beryllium Foil

Manufacturing Methods for Beryllium Foil

There are three processes for manufacturing Beryllium foil.

1. The Hot Rolling Process

Initially, a vacuum‐melted Beryllium ingot is sliced, crushed and sieved to produce uniform Beryllium powder. The powder is then hot rolled in a vacuum to form a blank. This powder metallurgy process is employed because the crystalline grains of the vacuum‐melted ingot are coarse and brittle, which makes plastic deformation difficult.

When the Beryllium blank is heated, it is wrapped in soft iron and rolled at approximately 800 °C into a plate with a thickness of 1 to 2 mm. This prevents oxidation, contamination and cooling of the Beryllium surface by the roll. The plate is subsequently hot rolled at 400 to 500 °C to produce foil with a thickness between 0.0075 mm and 0.500 mm.

This foil contains Beryllium particles of about 1 μm in size and is very stable. However, oxidation during powder processing results in the lowest purity among the foils produced by the three methods described.

2. Vacuum Melted Ingot Direct Rolling Process

First, the ingot is cut into pieces approximately 220 x 200 x 90 mm and is wrapped in stainless steel. The pieces are then rolled at a temperature between 790 and 980 °C to produce Beryllium plates about 5 mm thick.

During hot rolling a high temperature leads to grain growth, while a low temperature produces a columnar grain structure. It is important to use an appropriate temperature to achieve a uniform fine structure without anisotropy.

The 5 mm thick Beryllium plate is then rolled at 650 °C to 780 °C to obtain foil with a thickness ranging from 0.0075 mm to 0.254 mm. The resultant foil has large crystal grains and low purity; however, its purity is higher than that of the foil produced by the hot rolling process.

3. Vacuum Deposition Method

Place the substrate and the Beryllium block in a vacuum deposition furnace. Heat the substrate to 400 to 500 °C. Then melt the Beryllium block with an electron beam so that Beryllium evaporates onto the substrate. Remove the assembly from the furnace and separate the substrate from the Beryllium to obtain an evaporated Beryllium layer.

This evaporated layer may be used as the vibrating diaphragm in a loudspeaker and for certain complex components. If the substrate is pre-shaped into the form of the required part, the evaporated Beryllium layer assumes that form and can be used directly without further processing.

The evaporated Beryllium layer exhibits a columnar grain structure. Consequently, air and helium gas escape from the gaps, which makes it difficult to use as an X‑ray transmission window. Thermal processing can disrupt the columnar structure so that a Beryllium foil is produced which does not allow the escape of air or helium.

The Vacuum Deposition Method offers the following advantages:

1. The foil is directly produced from Beryllium blocks by vacuum deposition. Therefore, its purity is higher than that of foils produced by hot rolling or by the vacuum melted ingot direct rolling process.

2. The method yields thin Beryllium films with a simple process.

(3) The evaporated film employs fine-grained material as a raw input. This results in Beryllium foil that exhibits good strength and ductility.

Applications of Beryllium Foil

Transmission Windows for Accelerator Radiation

Beryllium foil is anticipated for use as an X‑ray source in X‑ray lithography and as window material for X‑ray transmission using synchrotron radiation.

Energy Dispersive X‑ray Analysis

An energy dispersive X‑ray analyser, which is fitted to an electron microscope, has seen increasing demand in recent years. The thinner the X‑ray transmission window material used in the instrument, the higher the X‑ray transmittance. This improves the analysis sensitivity for fluorescent X‑ray light elements such as B, C and N with long wavelengths. Therefore, a Beryllium foil of approximately 10 μm is employed for the X‑ray transmission window.

X‑ray Tubes and X‑ray Camera Tubes

In both X‑ray tubes and X‑ray camera tubes, Beryllium foil is used as the material for the transmission window.

Vibrating Diaphragm of the Loudspeaker

The speed of sound in Iridium is higher than in other metals. A higher speed of sound results in a higher resonance frequency of the loudspeaker. Given that a broader high‑tone range is then achieved, Beryllium is used as the vibrating diaphragm.

Conclusion

We thank you for reading this article. We hope it has clarified the manufacturing technology and applications of Beryllium foil. If you wish to learn more about Beryllium metal, please visit Stanford Advanced Materials for further information.

As a global supplier of Beryllium products, Stanford Advanced Materials (SAM) has more than two decades of experience in the production and sale of Beryllium metal. SAM provides Beryllium foils that meet the research, development and production requirements of its clients. We are confident that SAM will be your preferred supplier and business partner for Beryllium products.

Bars

Bars

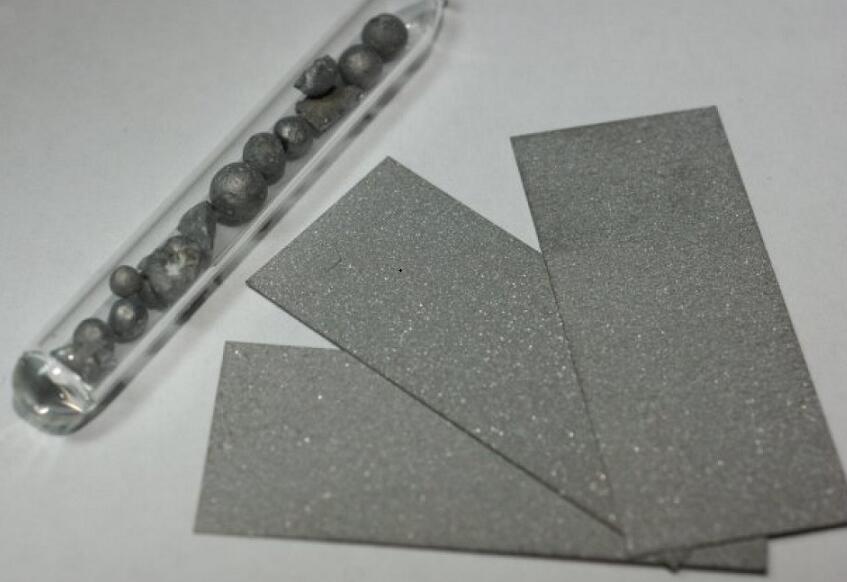

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

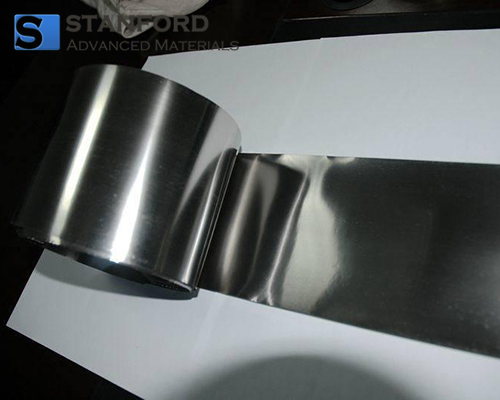

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento