Memory Alloys Reshape the Future of Mechanical Engineering

1 Introduction

In the history of engineering materials, we are entering a brand-new era of intelligence. Among these, shape memory alloys (SMA) stand out. This material possesses the ability to remember its original shape and recover its initial form from a deformed state under specific conditions, such as heating. This unique combination of shape memory effect and superelasticity transcends the limitations of conventional metals, driving innovation across multiple fields—from aerospace and biomedical applications to micro-robotics. Consequently, exploring how SMA leverages its inherent advantages to overcome limitations in traditional machinery—such as structural complexity, energy efficiency, and environmental adaptability—while analysing its core application value and future evolution trajectory emerges as a significant research endeavour.

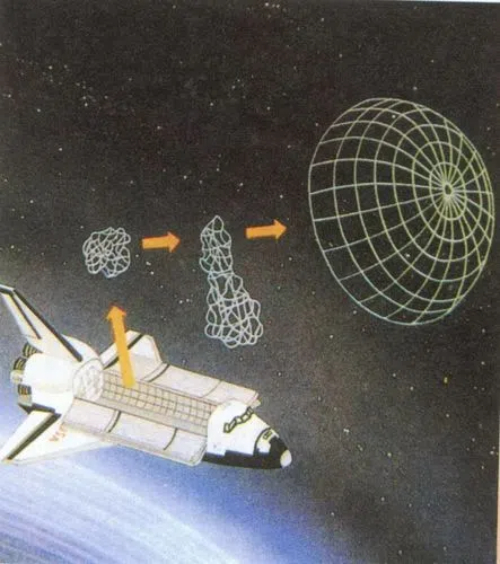

Fig. 1 Memory Alloys

2 Mechanism and Properties of Shape Memory Alloys

2.1 Core Mechanism: Martensitic Phase Transformation

Martensitic transformation is a non-diffusive phase transformation, also known as a displacement-type transformation. Strictly speaking, within displacement-type transformations, only those where atomic displacement occurs via shear, maintaining interface continuity and coherent macroscopic elastic deformation between phases, with sufficient strain energy to alter phase transformation kinetics and product morphology, qualify as martensitic transformations. A phase transformation where atoms are replaced without diffusion (i.e., composition and nearest-neighbour relationships remain unchanged) and undergo shear (resulting in a positional relationship between the parent phase and martensite), thereby altering their shape. This transformation generally refers to first-order nucleation and growth phase transformations (characterised by abrupt changes in heat and volume, such as exothermic reactions and expansion).

Martensitic transformation exhibits thermal and volumetric effects, with the transformation process involving nucleation and growth. However, no comprehensive model exists yet to explain how nuclei form and grow. Martensite growth rates are high, sometimes reaching up to 10 cm/s. It is hypothesised that the configuration of crystal defects (such as dislocations) in the parent phase influences martensite nucleation. Yet, experimental techniques cannot yet observe the configuration of dislocations at the phase boundary, preventing a complete understanding of the martensitic transformation process. Its characteristics can be summarised as follows:

Martensitic transformation is a diffusionless phase transformation. During this process, atoms do not undergo a random walk or sequential hopping across interfaces. Consequently, the new phase (martensite) inherits the chemical composition, atomic order, and crystal defects of the parent phase. Atoms undergo ordered displacement, maintaining their relative positions with neighbouring atoms. This displacement is shear-type. The resultant atomic displacement generates lattice strain (or deformation). This shear displacement not only alters the lattice structure of the parent phase but also induces macroscopic shape changes. Consider a straight line PQRS etched onto the surface of a polished specimen. If a portion of the specimen (A1B1C1D1-A2B2C2D2) undergoes martensitic transformation (forming martensite), the line PQRS will bend into three connected segments: PQ, QR', and R'S', while the planes A1B1C1D1 and A2B2C2D2 at the two-phase interface remain strain-free and rotation-free, termed habitual (precipitation) planes. This shape change is called invariant plane strain. The resulting deformation creates protrusions on the pre-polished specimen surface. Surface protrusions in high-carbon steel martensite reveal tilting at the interface during martensite formation. Under an interference microscope, the height of these protrusions and their sharp, well-defined edges become visible.

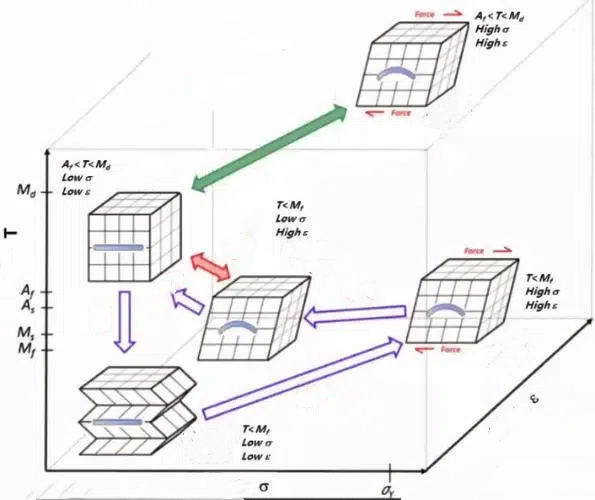

Fig. 2 Martensitic Phase Transformation

2.2 Two Key Features

1. Shape Memory Effect, SME

The shape memory effect refers to the ability of SMA to fully recover its initial memorised shape after undergoing plastic deformation at low temperatures, by heating it above a critical temperature (known as the austenite transformation completion temperature, Af).

The memory capability of shape memory alloys is not inherent but is imparted through a thermomechanical treatment process called training. Essentially, this process creates a preferred orientation within the material through heat treatment and deformation, serving as a template for martensite formation during cooling and austenite recovery during heating.

The training process primarily involves the following steps:

Setting the Shape: The alloy is heated to a very high temperature (typically well above Af, e.g., over 500°C) and processed into the desired memory shape (e.g., a straight wire). At this elevated temperature, the alloy exists in the austenite phase, exhibiting a highly ordered cubic crystal structure. Maintaining this shape during a prolonged heat treatment effectively imprints this ordered structure as the final shape to be recovered.

Constraint and Cooling: The alloy is cooled under constrained conditions (e.g., bending it into a coil and securing it before cooling). This process ensures that during subsequent phase transformations, internal stress fields are released along the predefined path.

Stabilisation: After multiple heat-constraint-cool cycles, stable dislocation arrays and stress fields form within the alloy. This enables the material to learn reversible transformation between two forms: one in the low-temperature martensite phase and another in the high-temperature austenite phase.

Shape memory alloys primarily exhibit either unidirectional or bidirectional memory. Unidirectional memory is the most common type. After deformation at low temperatures, the alloy recovers its memory shape solely through heating. However, upon subsequent cooling, it does not automatically revert to the deformed shape and requires external force. Most commercial applications (such as stents and actuators) rely on this effect. The bidirectional memory effect, achieved through specialised training, enables the alloy to not only revert to its high-temperature shape (austenite) upon heating but also automatically and reversibly return to a distinct low-temperature shape (martensite) during cooling. This effect allows cycling between the two shapes without external force, though the training process is more complex and typically results in shorter fatigue life.

Fig. 3 Shape Memory Effect

2. Superelasticity, SE/ Pseudoelasticity

Superelasticity refers to the phenomenon where SMA, when subjected to external forces above its Af temperature (i.e., fully in the austenite phase), undergoes seemingly plastic deformation far exceeding that of conventional metals (reaching 8% or higher). However, upon unloading, the deformation immediately and automatically recovers. Because it appears like elastic deformation yet involves a vast strain range, it is termed superelasticity or pseudoelasticity.

The physical essence of this phenomenon is stress-induced martensitic phase transformation. When the material is in the austenitic state (a high-temperature phase with a stable crystal structure), applying stress beyond a critical threshold causes it to yield not through dislocation slip (the conventional plastic deformation mechanism in metals), but by inducing localized transformation of austenite into martensite. This martensite is termed stress-induced thermoelastic martensite. The phase transformation consumes mechanical energy, manifesting as a stress plateau (a nearly flat region on the stress-strain curve where strain increases significantly while stress remains largely constant). When stress drops below another critical threshold, the martensite undergoes immediate reverse transformation back to austenite—as it is thermodynamically unstable above the Af temperature—resulting in complete macroscopic shape recovery. This recovery process similarly forms a stress plateau.

Superelastic Ni-Ti alloys (Nitinol) are widely used in eyeglass frames, dental orthodontic wires, soft mechanisms, and vascular stents. These products exhibit superelasticity at room temperature (above Nitinol's Af temperature), enabling them to withstand significant deformation without permanent damage.

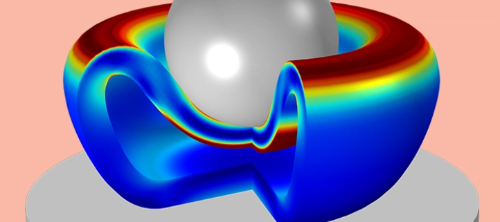

Fig. 4 Simulation of the Compression of Hyperelastic Materials

2.3 Common Types

Among the numerous shape memory alloys, Nitinol undoubtedly stands out as the most exceptional and widely applied representative. This nickel-titanium alloy is renowned for its outstanding properties, boasting the highest shape memory strain recovery rate and superelasticity, coupled with excellent fatigue life and biocompatibility. These qualities make it the mainstay in medical implant fields such as cardiovascular stents and orthodontic wires. Despite its higher cost and complex processing, the ability to precisely control phase transition temperatures by adjusting its composition makes it equally necessary in aerospace and precision robotics.

Fig. 5 Nitinol Guide Wire

In contrast, copper-based shape memory alloys, represented by Cu-Zn-Al and Cu-Al-Ni, follow a different path. Their greatest advantage lies in low cost and the ability to activate memory effects at higher temperatures. However, their performance limitations are also pronounced: typically exhibiting significant thermal hysteresis, low fatigue life, and inherent brittleness. These characteristics restrict their use in high-precision, high-reliability applications, confining them primarily to cost-sensitive commercial products like thermostatic switches and electrical contactors.

Iron-based shape memory alloys, particularly Fe-Mn-Si alloys, have pioneered another significant direction. Their greatest appeal stems from extremely low raw material costs coupled with high strength and stiffness comparable to ordinary steel. Although exhibiting smaller recovery strain and less pronounced superelasticity, their excellent machinability (good casting, rolling, and welding properties) and ability to provide substantial driving forces make them suitable for macro-engineering applications like pipeline connections and large-scale structural seismic dampers. This demonstrates the immense potential of shape memory technology in large-scale industrial applications.

3 Core Applications of Shape Memory Alloys in Mechanical Engineering

3.1 Intelligent Actuation and Drive

The core application principle of shape memory alloys lies in their unique thermodynamic phase transition behaviour: when heated above the critical temperature, the alloy transforms from its low-temperature martensite phase to the austenite phase. This induces a reversible rearrangement of its internal crystal structure, manifesting macroscopically as the material's ability to contract and generate substantial restoring force. This process directly converts input thermal energy into mechanical energy output. Conversely, during cooling, the material readily reorients under external force, preparing for the next work cycle. This integrated thermal-to-mechanical energy conversion makes it a compelling smart actuation material.

In the high-tech aerospace sector, the actuation capabilities of shape memory alloys find applications. For instance, modern aircraft require dynamically adjustable intake duct grilles to optimise engine efficiency based on speed and altitude. Traditional hydraulic or motor systems are complex and cumbersome, whereas actuators made from shape memory alloys can be precisely controlled via simple electrical heating to extend or retract, accurately regulating grille opening and closing. Furthermore, in adaptive wing technology, alloy components embedded within wing skins or structures enable continuous aerodynamic shape changes through temperature control. This replaces traditional hinged control surfaces, significantly reducing drag and noise. In space environments, satellite solar panels and antennas must be tightly folded during launch to fit within the fairing, then reliably deployed after orbital insertion. Release mechanisms or deployment hinges based on shape memory alloys can smoothly and silently complete deployment tasks upon sensing thermal radiation in space or activation by onboard heaters, offering greater reliability than traditional pyrotechnic explosive mechanisms.

In robotics, shape memory alloys are driving a change in actuation methods. They are hailed as the ideal material for creating artificial muscles. In bionic robots, fingers, necks, or limb joints can mimic muscle bundle contraction and relaxation using bundled Nitinol wires. By controlling heating and cooling rhythms through pulsed currents, these alloy muscles achieve near-natural motion while simplifying traditional transmission structures like gears and motors, significantly reducing overall weight. This advantage is particularly pronounced in micro- and soft-robotics, where conventional electromagnetic motors become inefficient at these scales. Shape memory alloy wires can deliver effective power output even at the millimetre or micrometre level, driving the joints or fins of micro-robots to achieve dexterous crawling or swimming motions.

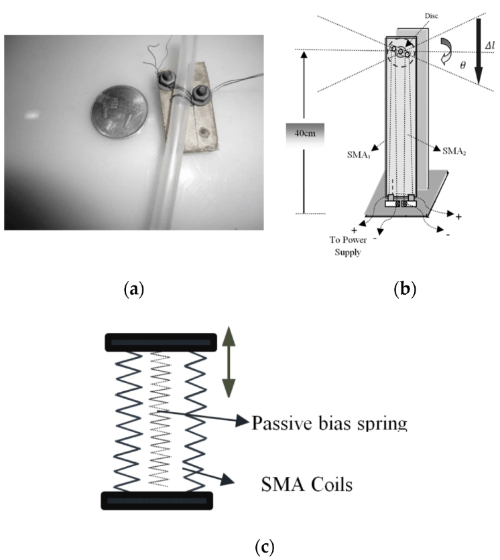

In industrial automation, shape memory alloy actuators offer novel solutions with their silent operation, non-magnetic properties, and compact design. Microfluidic control systems exemplify this application. Traditional solenoid valves generate noise and magnetic interference during operation, posing risks in explosion-proof or clean environments. In contrast, microvalves driven by shape memory alloy springs precisely regulate opening via programmable electrical heating signals, enabling fluid on/off control and flow regulation. This process generates virtually no audible noise and produces no electromagnetic interference, making it particularly suitable for applications demanding extreme quietness and electromagnetic compatibility. Examples include medical analytical instruments, precision laboratory equipment, and climate control systems in luxury automobiles.

Fig. 6 Memory Alloys for Smart Actuation

3.2 Efficient Connections and Fastening

The core application principle of shape memory alloys lies in their ability to directly convert thermal energy into mechanical energy. Their driving force originates from the recovery stress released during the material's martensitic reverse transformation (heating to restore the austenitic phase). This stress is not generated by conventional electromagnetic effects or mechanical transmission, but rather stems from the intrinsic nature of the material's internal crystal structure rearrangement. This provides the physical foundation for achieving exceptionally simple and reliable mechanical actuation.

In aerospace and precision instrumentation, this principle is applied to manufacture high-performance pipe fittings. Traditional fluid conduit connections like welding or threaded joints risk stress concentration, uneven sealing, or loosening under severe vibration. Sleeve-type pipe fittings made from NiTiN (nickel-titanium nitride) with unidirectional memory effect feature an inner diameter mechanically expanded at low temperatures. When heated above its transformation temperature at the installation site, it forcefully contracts back to its memorised smaller diameter. This creates a powerful clamping force against the connected pipe, achieving a uniform 360° seal. This connection not only provides exceptional sealing but also effectively resists fatigue and vibration. Since its recovery stress is continuously present, its reliability far surpasses traditional methods, making it essential in aircraft hydraulic systems, fuel lines, and deep-sea exploration equipment.

In mechanical and electronic industries, the superelastic properties of shape memory alloys also shine. Contact pins in IC sockets are a prime example. As chip pin pitches continue to shrink, traditional spring-loaded probes face challenges of manufacturing complexity and unstable contact pressure. Contact pins made from superelastic Nitinol wire undergo stress-induced phase transitions when compressed by chip pins during testing, generating substantial, near-constant elastic deformation. Upon pin release, the pins instantly and fully recover. This process delivers exceptionally stable and repeatable contact pressure, ensuring signal integrity during testing. Its outstanding fatigue life enables millions of test cycles, making it a core component in high-reliability testing.

Furthermore, this principle extends to orthopedic fixation in medical implants. While biocompatibility is paramount, from a mechanical perspective, orthopedic compression screws or plates made from shape memory alloys—implanted in a low-temperature deformed state and restored to shape by body heat—deliver sustained, self-applied compression at fracture sites. This promotes bone healing, demonstrating the work performed by the material's restorative force.

Fig. 7 Memory Alloys Are Used in Aerospace Applications

3.3 Safety Protection and Sensing

The intelligence of shape memory alloys stems from their precise phase transition behaviour, with their core applications ingeniously leveraging two critical thresholds: the phase transition critical temperature and the critical stress. These parameters function as the material's smart switches. When the ambient temperature or mechanical stress reaches a preset critical point, they trigger a phase transition in the material, enabling it to execute predetermined mechanical actions or alter its own mechanical properties. This achieves automatic responses without requiring complex external control.

In the field of thermally sensitive protection devices, this property is harnessed to construct exceptionally simple and reliable passive safety systems. The principle involves precisely setting the phase transition critical temperature of an SMA component (such as a spring or actuator) at a specific safety threshold. For instance, in the trigger mechanism of an electrical overheat protection switch or a fire alarm, a pre-compressed SMA spring remains compressed at normal temperatures, maintaining electrical continuity. Once the ambient temperature rises due to a fault or fire and exceeds its critical temperature, the spring rapidly recovers its stored elongation state, generating significant displacement to instantly break the circuit or activate the alarm device. This entire process is entirely driven by the material's inherent properties, requiring no power source or sensors, ensuring reliability and suitability for applications demanding high safety standards with passive safeguards.

In engineering vibration control, SMA's phase-change properties are leveraged to develop advanced smart dampers. These applications employ a sophisticated principle, utilising both temperature- and stress-induced phase transitions. When incorporated as the core energy-dissipating element within a damper, the SMA component is engineered with a critical stress threshold. During normal-amplitude vibrations in structures like bridges, high-rise buildings, or precision platforms, stress levels remain below this threshold. In this state, the SMA remains in its austenitic phase, providing high stiffness to maintain normal operational dynamics. However, during extreme events like strong winds, earthquakes, or massive impacts, intensified structural vibrations cause stresses exceeding the critical threshold. This triggers a martensitic phase transition within the SMA element. The phase transition process absorbs substantial mechanical energy (vibration energy), rapidly damping vibration amplitude. More intelligently, the altered material stiffness post-transformation also shifts the structure's natural frequency, preventing resonance with external excitation and safeguarding the main structure's integrity. This integrated capability of energy dissipation and frequency modulation demonstrates SMA's potential as a smart material for enhancing the resilience of engineering systems.

Fig. 8 Temperature-Controlled Thermosensitive Gasket

3.4 Energy Absorption and Dissipation

The superelastic deformation capability of shape memory alloys provides a unique mechanism for energy absorption, fundamentally stemming from the substantial hysteresis loops exhibited during stress-induced martensitic phase transformation and its reverse phase transformation. When an elastically superplastic SMA element is loaded, the stress plateau consumes mechanical energy to complete the austenite-to-martensite transformation. During unloading, the stress plateau of the reverse transformation also requires energy. The difference between these two plateaus—the area enclosed by the hysteresis loop—represents the energy absorbed and dissipated by the material within a single cycle. This physical property makes it an ideal passive energy-dissipating material.

In seismic engineering, this principle is applied to the damper systems of new buildings and bridges. These superelastic SMA elements (often fabricated as rods or strands) are integrated into structural supports or connections. Under conventional wind vibrations or minor seismic events, structural stresses remain below the SMA's critical threshold. The material remains in its rigid austenitic state, providing sufficient stiffness for normal structural operation. However, during intense seismic events, structural deformation rapidly increases, causing stresses within the SMA to exceed the critical threshold. This triggers a large-scale stress-induced phase transition. Functioning like a mechanical fuse, this phase transition converts violent seismic kinetic energy into heat through a hysteresis effect, dissipating it effectively. This process suppresses structural vibrations and protects the main structure from catastrophic deformation. Notably, due to its superelasticity, the damper automatically returns to its original shape and position after load removal following an earthquake. Unlike traditional dampers requiring replacement, this achieves structural self-resetting, significantly enhancing post-earthquake functional recovery.

In human impact protection, the energy-absorbing properties of superelastic SMA enhance equipment safety. For instance, high-performance sports helmets incorporate SMA materials or composite layers within their inner lining structures. During collisions, the impact force induces superelastic deformation in the SMA components. Their broad hysteresis loop enables them to absorb and dissipate energy more effectively than other elastic materials, thereby reducing peak acceleration transmitted to the head and mitigating concussion risks. Similarly, replacing traditional underwire with superelastic NiTi wire in sports bra support structures not only delivers improved suppleness and comfort but also provides critical cushioning protection during unexpected impacts or vigorous movement. At the moment of collision, SMA components absorb impact energy through phase transition, mitigating chest force, then automatically revert to their original shape. This maintains product durability and the sustainability of protective functionality.

4 Strengths, Challenges, and Future Outlook

4.1 Summary of Core Advantages

The core advantage of shape memory alloys lies in their disruption of traditional mechanical system design paradigms. They integrate actuation, sensing, and structural functions into a single unit, creating a highly integrated intelligent system. Their most distinctive feature is an exceptionally high power-to-weight ratio, meaning they can generate substantial actuation forces or recover stresses with little mass. This characteristic holds importance for weight-sensitive fields such as aerospace and micro-robotics, enhancing system energy efficiency.

Simultaneously, the operational mechanism of SMA actuators is fundamentally a solid-state phase transition. This eliminates the need for complex transmission components like traditional motors and gearboxes, realising the concept of material as machine. This actuation method not only simplifies mechanical structures by reducing moving parts and potential failure points—enhancing system reliability—but also delivers clean advantages: silent operation, absence of electromagnetic interference, and zero wear debris. This makes SMA a solution in semiconductor manufacturing equipment requiring cleanliness, medical instruments demanding quiet environments, and precision detection devices needing to avoid magnetic interference.

Ultimately, SMA's multifunctionality elevates its value. It is no longer a passive component but an active unit capable of sensing environmental stimuli (such as temperature or stress changes) and responding (by driving or altering stiffness). This triple functionality—sensing, driving, and structural support—lays the foundation for constructing adaptive smart structures, marking a transition in mechanical engineering from reliance on complex mechanisms to harnessing the inherent intelligence of materials.

4.2 Current Challenges

Despite the potential of shape memory alloys, their path to large-scale engineering applications remains hindered by challenges that require solutions. First, their response speed is constrained by the inherent thermal cycling process: while electrical heating can quickly induce phase-change contraction, the subsequent cooling and heat dissipation often rely on environmental heat exchange. This bottleneck limits actuation frequency, rendering them unsuitable for scenarios requiring high-frequency reciprocal motion.

Second, an energy efficiency dilemma exists. While SMAs exhibit high energy conversion efficiency when generating displacement and force, maintaining specific shapes or states (such as sustained contraction) requires continuous electrical input to compensate for thermal losses. This results in significant static energy consumption, posing a burden for battery-powered portable devices or spacecraft undergoing long-term orbital operations.

Additionally, high material and control system costs present barriers to commercialisation. The raw materials and precision fabrication processes for high-performance NiTiN alloys are costly. Achieving precise, reliable actuation requires supporting systems including temperature sensors, feedback circuits, and complex control algorithms, substantially increasing overall solution complexity and total cost.

Finally, long-term reliability faces the challenge of fatigue life. During repeated phase transition cycles, materials gradually accumulate damage due to internal dislocation proliferation and grain boundary migration. This leads to degradation in critical properties such as driving strain and recovery stress, ultimately causing component failure. Enhancing the stability and durability of phase transition cycles is fundamental to ensuring reliable operation in crucial safety applications. Collectively, these challenges represent the obstacles currently limiting the broader adoption of shape memory alloys.

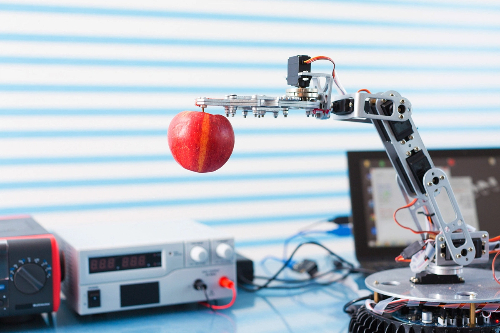

Fig. 9 Application in Various Types of Robotic Systems

4.3 Future Development Trends

The future development of shape memory alloys will unfold along two dimensions: overcoming existing bottlenecks and pioneering new application paradigms. Its evolutionary trajectory entails interdisciplinary convergence. The primary breakthrough lies in developing new materials. Researchers are designing and fabricating novel memory alloy systems with higher phase transition temperatures, longer fatigue lifespans, and lower costs through methods such as multi-component alloying and nano-precipitation. Examples include developing high-temperature SMAs stable above 200°C or more economical iron-based and copper-based high-performance materials to widen their application boundaries.

Simultaneously, the evolution of intelligent control strategies will significantly unlock SMA's potential. By integrating artificial intelligence and machine learning algorithms, control systems can leverage historical data and real-time feedback to predict and adaptively manage SMA's complex thermo-mechanical coupling behaviour. This approach addresses control challenges posed by nonlinear hysteresis, achieving smooth, precise, and efficient actuation performance.

Future system architectures will increasingly adopt hybrid design philosophies. SMAs will no longer be viewed as replacements for traditional actuators but as collaborative units integrated with other actuation technologies—such as electromagnets, hydraulic systems, or piezoelectric ceramics—to form hybrid systems. This aims to harness complementary strengths: for instance, utilising SMAs' high power-to-weight ratio and silent operation for macro-displacement while employing piezoelectric ceramics' rapid response for high-frequency fine-tuning, thereby integrating multiple advantages.

Ultimately, additive manufacturing (4D printing) technology will revolutionise design freedom for SMA. It enables the direct fabrication of integrated smart components featuring complex internal structures and preprogrammed deformation sequences. Under specific stimuli, these components autonomously fold, unfold, or twist from two-dimensional or simple three-dimensional forms into their final functional configurations according to programmed designs. This facilitates true structure-as-function, delivering customised intelligent deformation solutions for reconfigurable robots, adaptive aerospace structures, and next-generation medical devices.

5 Conclusion

Shape memory alloys, as representatives of smart materials, are fundamentally reshaping the design paradigm of mechanical engineering through their unique shape memory effect and superelasticity. They propel mechanical systems from conventional configurations reliant on complex gears, linkages, and motors toward intelligent evolution characterised by simplified structures, reduced weight, and integrated functionality. This represents not merely an advancement in a single material technology, but a fundamental change in design philosophy—where the task of engineers shifts from merely designing mechanisms to achieve motion and function to “designing the material itself.” By endowing materials with intelligent responsiveness, they become new entities capable of sensing, driving, and bearing structural loads.

Looking ahead, as materials scientists achieve breakthroughs in developing novel alloys (such as high-temperature, low-cost SMAs) and control algorithms deeply integrate with artificial intelligence technologies, shape memory alloys will become more embedded in our mechanical world. They will expand beyond critical aerospace and medical applications into broader industrial uses and everyday life, leading to smart structures and systems beyond current imagination. Ultimately, this will herald a new mechanical era characterised by autonomous sensing, intelligent responsiveness, and adaptive transformation.

For engineers and designers looking to explore or source these advanced materials, Stanford Advanced Materials (SAM) offers a comprehensive range of shape memory alloys and related smart materials to support innovation and application.

Reference:

[1] Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

[2] Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

[3] Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modelling and engineering applications. Springer Science & Business Media.

[4] Ma, J., Karaman, I., & Noebe, R. D. (2010). High temperature shape memory alloys. International Materials Reviews, 55(5), 257-315.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento