Uses Of Molybdenum Alloys In The Aerospace And Steel Industry

Molybdænlegierungen are used owing to their high strength, mechanical stability and ductility. They find applications in high-temperature heating elements, extrusion grinding tools, glass melting electrodes, spray coatings, metal fabrication tools and aerospace components.

Use of Molybdænlegierungen in the aerospace and steel industries

Applications of Molybdænlegierungen in the Aerospace Industry

Commercially, Molybdæn–copper alloys are used in the aerospace sector. They serve as non-ferrous alloys with Molybdæn as the matrix and include elements such as Titanium, Zirconium, Hafnium, Tungsten and Rare Earths.

These alloying elements provide solid-solution strengthening and maintain low-temperature plasticity. They also form a stable, dispersed carbide phase which improves the alloy strength and recrystallisation temperature.

Applications of Molybdænlegierungen in the Steel Industry

Molybdæn accounts for the largest proportion in the steel industry.

It is mainly used in the production of alloy steel, accounting for approximately 43% of the total Molybdæn consumption in the steel industry. It is also used in the production of stainless steel (approximately 23%), tool steel and high-speed steel (approximately 8%), cast iron and rollers (approximately 6%).

The majority of Molybdæn is employed directly in steel production or in cast iron following industrial Molybdæn oxide briquetting. A smaller fraction is first melted into ferromolybdæn and then used in steel production.

Molybdæn as an Alloying Element in Steel Confers the Following Advantages:

- Enhanced strength and toughness of steel;

- Improved corrosion resistance in acid–base solutions and liquid metals;

- Increased wear resistance;

- Better hardenability, weldability and heat resistance.

Hence, stainless steel with a Molybdæn content of 4% to 5% is frequently used in environments with significant erosion and corrosion, for example in ship fittings and chemical plants.

Conclusion

Thank you for reading this article. We hope it has improved your understanding of the applications of Molybdænlegierungen in the aerospace and steel industries.

If you wish to learn more about Molybdænlegierungen and other refractory metals and alloys, we recommend that you visit Stanford Advanced Materials (SAM) for further information.

As a leading supplier of Molybdæn products, SAM has over two decades of experience in the manufacture and distribution of Molybdænlegierungen, Molybdæn tubes and Molybdæn powder. It supplies Molybdæn products that meet rigorous standards for research and production requirements. We trust that SAM will be your preferred supplier and business partner for Molybdæn products.

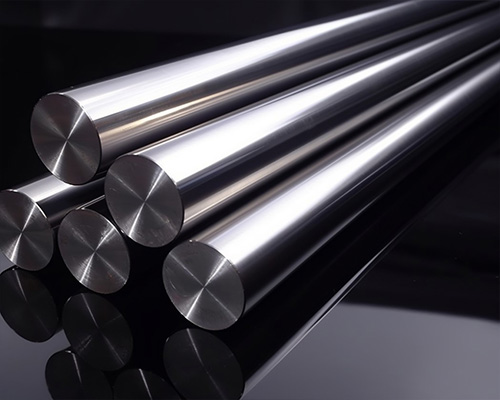

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento