SAM Launches Polymer Tungsten For Radiation Shielding

Introduction

Stanford Advanced Materials (SAM), the industry leader in materials, is proud to announce the release of its new polymer tungsten for radiation shielding. This development contributes to environmentally friendly solutions for radiation shielding.

Rita from SAM explains, “Tungsten is an excellent radiation material, but it is too brittle to be shaped as required. However, mixing tungsten powder with polymer produces a flexible radiation-resistant material. SAM continually seeks innovative ways to meet customer needs. Given the environmental costs of lead, poly tungsten is poised to replace it in the coming years.”

Case Study: Stanford Advanced Materials' Polymer Tungsten for Eco-Friendly Radiation Shielding

The Challenge

In the medical sector, lead has been the standard material for radiation shielding due to its high density and effectiveness. However, lead poses significant health and environmental risks, being toxic and difficult to dispose of safely. Moreover, its rigidity limits design flexibility, making it challenging to mould into complex shapes required for modern medical equipment. The industry required a safer, more adaptable alternative that maintained or exceeded lead's shielding capabilities.

The Solution

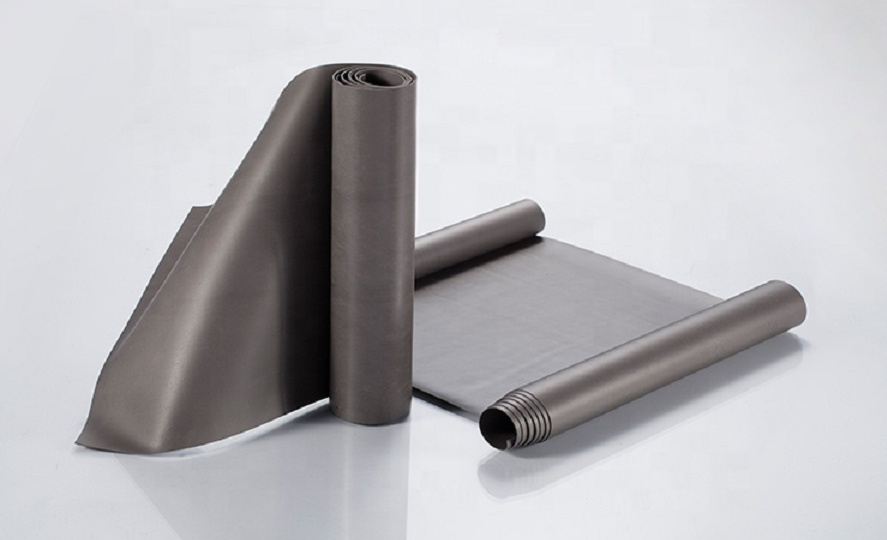

Stanford Advanced Materials (SAM) addressed this challenge by developing Polymer Tungsten, a composite material that combines tungsten powder with various polymers. Tungsten offers excellent radiation shielding properties, similar to lead, but is inherently brittle. By integrating tungsten with polymers, SAM created a flexible, machinable, and environmentally friendly material.

This composite, also known as PolyTungsten, retains the high density necessary for effective radiation shielding while eliminating the toxicity associated with lead. Its flexibility allows for easy moulding into complex shapes, making it suitable for a wide range of medical applications.

The Results

Polymer Tungsten has demonstrated several advantages over traditional lead shielding.

· Equivalent or Superior Shielding: PolyTungsten provides radiation shielding performance comparable to lead, effectively blocking harmful radiation without leakage or hot spots.

· Environmental and Health Safety: Being non-toxic and compliant with UK HSE, and RoHS standards, it poses fewer health risks and environmental concerns.

· Design Flexibility: The material's pliability allows for easy machining and moulding, enabling the production of complex shapes required in modern medical devices.

· Durability: PolyTungsten maintains its form during use, ensuring long-term reliability in medical settings.

What is Polymer Tungsten?

Polymer Tungsten (also known as Tungsten-filled Polymer and PolyTungsten) is a composition of various resins and tungsten powder mixed through special metallurgical technology. Compared with other materials, tungsten poly has unique properties: it can be easily machined, has high radiation resistance, and is environmentally friendly.

Polymer Tungsten is increasingly used in applications where precision, safety, and sustainability are essential:

· Medical Imaging Equipment – X-ray and CT shielding panels, collimators, detector covers

· Nuclear Medicine – Syringes, vials, and radiation therapy devices

· Personal Protection – Lightweight shielding garments and inserts

· Industrial Radiography – Custom shielding for NDT (non-destructive testing) systems

· Aerospace and Defence – Satellite components requiring radiation hardening

Polymer Tungsten vs. Lead for Radiation Shielding

Traditionally, lead (Pb) was the preferred choice for shielding against radiation. It is inexpensive and abundant, but it is toxic and highly hazardous. In fact, it is ranked number two on the United Kingdom’s “Priority List of Hazardous Substances”.

Poly Tungsten has the same density and thickness as lead, thus providing equivalent shielding properties. Additionally, it offers improved durability and is more environmentally friendly. It is non-toxic, reliable, and meets UK HSE, RoHS standards. Furthermore, it retains its form during use and can be applied in various contexts, such as X-ray equipment, CT scanning devices, tungsten poly syringes, and tungsten poly collimators, among others. Analyses of both samples and actual products confirm that SAM’s tungsten-filled polymer products provide radiation shielding that is superior to lead material shielding without leakage or hot spots.

Below is a detailed comparison table of polymer tungsten vs. lead for radiation shielding.

|

Property |

Lead |

Polymer Tungsten |

|

Density |

~11.34 g/cm³ |

Up to 11 g/cm³ |

|

Toxicity |

High (requires special handling and disposal) |

Low (non-toxic and RoHS compliant) |

|

Environmental Risk |

Significant |

Minimal |

|

Design Flexibility |

Limited |

High – easily moulded or extruded |

|

Recyclability |

Challenging |

Easier (thermoplastics can be reused) |

|

Durability |

Brittle, soft |

Structurally stable, impact-resistant |

Why Choose SAM’s Polymer Tungsten?

Stanford Advanced Materials (SAM) is at the forefront of high-performance materials innovation. Our Polymer Tungsten solutions are:

· Tailored to your application

· Tested and certified

· Custom-formulated

Whether you are designing radiation-shielded syringes, protective panels, or precision imaging components, SAM’s Polymer Tungsten provides the performance of metal with the versatility of plastic.

Conclusion

Thank you for reading our article, we hope it assists in understanding the polymer tungsten for radiation shielding. To learn more about tungsten products, please visit Stanford Advanced Materials (SAM) for further information.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento