SAM Launches Tantalum Marker Bands For The Medical Industry

Tantalum Marker Bands for the Medical Industry

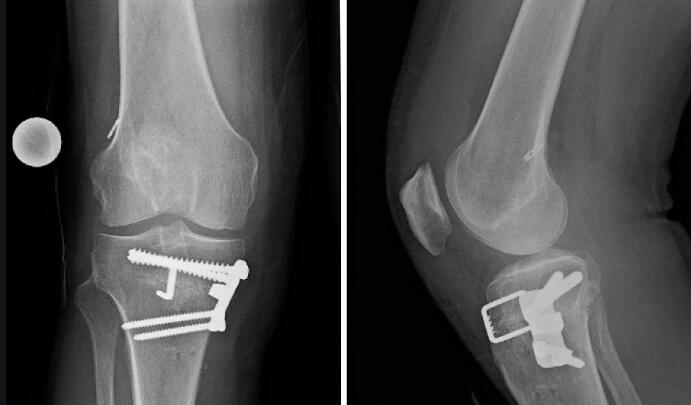

Stanford Advanced Materials (SAM), the leading supplier of materials, is pleased to introduce customised tantalum marker bands for the medical industry. Radiopaque marker bands are thin-walled metal tubes affixed at specific points on a catheter to improve visibility under X‑ray fluoroscopy.

Molly Wang of Stanford Advanced Materials (SAM) stated: "Currently, marker bands are manufactured using high‑density metals such as platinum and gold. These precious metals are scarce, thereby driving up production costs – recently, prices of up to 56 $/g for platinum have been reported."

Tantalum Marker Bands vs. Platinum Marker Bands

Tantalum is less expensive than platinum; however, it presents manufacturing challenges. Although tantalum is a suitable substitute for platinum, it has been largely disregarded given the difficulties in production.

SAM has addressed this issue and now offers tantalum marker bands that yield equivalent performance to platinum or other marker bands while incurring only a fraction of the cost. In the near future, platinum marker bands will be replaced, given that tantalum is gaining prominence.

Advantages of Tantalum Marker Bands

Marker bands assist in guiding and positioning catheters during medical procedures, particularly when X‑ray visibility is required. SAM’s marker bands are manufactured under strict dimensional tolerances and without burrs.

Tantalum Marker Bands for the Medical Industry

Why Choose SAM?

With years of experience and industry expertise, SAM is capable of manufacturing tantalum marker bands with tight tolerances, thinnest walls and optimal surface and edge conditions within the medical technology sector.

Tantalum marker bands are produced to customer specifications in a range of diameters. SAM stocks various sizes of tantalum marker bands for immediate requirements.

Bars

Bars

Beads & Spheres

Beads & Spheres

Bolts & Nuts

Bolts & Nuts

Crucibles

Crucibles

Discs

Discs

Fibers & Fabrics

Fibers & Fabrics

Films

Films

Flake

Flake

Foams

Foams

Foil

Foil

Granules

Granules

Honeycombs

Honeycombs

Ink

Ink

Laminate

Laminate

Lumps

Lumps

Meshes

Meshes

Metallised Film

Metallised Film

Plate

Plate

Powders

Powders

Rod

Rod

Sheets

Sheets

Single Crystals

Single Crystals

Sputtering Target

Sputtering Target

Tubes

Tubes

Washer

Washer

Wires

Wires

Converters & Calculators

Converters & Calculators

Write for Us

Write for Us

Chin Trento

Chin Trento